Electrochemical scale removing device

A descaling, electrochemical technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., to achieve the effect of extending the service period, reducing the risk of corrosion, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

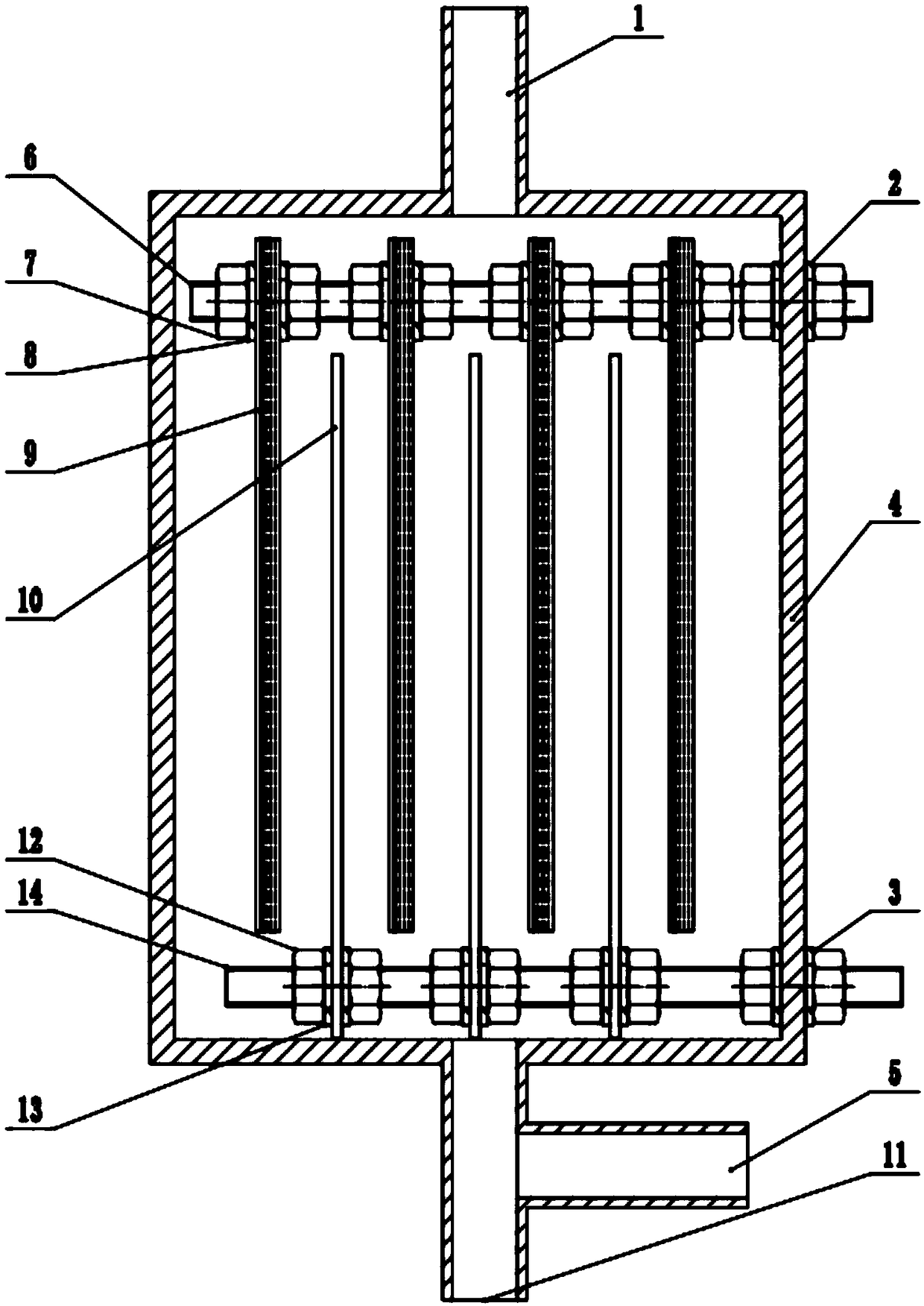

[0023] Such as figure 1 , an electrochemical descaling device, mainly includes a cathode 9 and an anode 10, the cathode 9 is nailed with 7 layers of stainless steel wire mesh, and the mesh numbers of the stainless steel wire mesh forming the cathode are 20 mesh, 12 mesh, 8 mesh, 50 mesh Mesh, 8 mesh, 12 mesh, 20 mesh. The cathode is fixed with stainless steel bolts 6 , nuts 7 and gaskets 8 , and the anode 10 is a DSA anode and fixed with titanium alloy bolts 14 , nuts 12 and gaskets 13 . The distance between adjacent cathodes and anodes is 3 mm. The equipment is placed vertically as a whole, and the water inlet 5 and the slag discharge port 11 are at the bottom of the equipment. During water intake, the pipeline valve at the lower part of the slag unloading port 11 is closed, and water flows in through the water inlet 5 and flows out through the water outlet 1 at the top.

[0024] Specifically, before the operation of the device, the positive pole of the DC constant current...

Embodiment 2

[0034] Such as figure 1 , an electrochemical descaling device, the spacing between adjacent cathodes and anodes is 5mm and 8mm, and the rest of the device parameters and operating conditions are the same as in Example 1. The relationship between the distance between adjacent cathodes and anodes and the performance of the descaler is shown in Table 2. It can be seen that the increase in the distance between adjacent cathodes and anodes does not significantly increase the descaling efficiency, but it significantly increases the descaling required. energy consumption. Therefore, the cathode and anode of the present invention are arranged alternately and closely to achieve the purpose of energy saving.

[0035] Table 2: Effect of spacing of adjacent cathodes and anodes on descaler performance

[0036]

Embodiment 3

[0038] Such as figure 1, an electrochemical descaling device, the multi-layer wire mesh constituting the cathode is selected from stainless steel mesh, copper mesh, nickel mesh and titanium mesh respectively, and the remaining device parameters and operating conditions are the same as in Example 1. The relationship between the material of the wire mesh that makes up the cathode and the performance of the descaler is shown in Table 3. It can be seen that the device uses wire mesh made of nickel, titanium and other materials to achieve better descaling performance, and the material used is stainless steel. And copper wire mesh has higher descaling rate and lower energy consumption.

[0039] Table 3: Effect of the wire mesh material making up the cathode on the performance of the descaler

[0040]

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com