Environmentally friendly waterproof leakage stopping material, preparation method and application

A waterproof blocking and environmental protection technology, applied in the field of building construction, can solve the problems of poor bending strength, etc., and achieve the effects of high bending strength, not easy to crack, and good acid resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

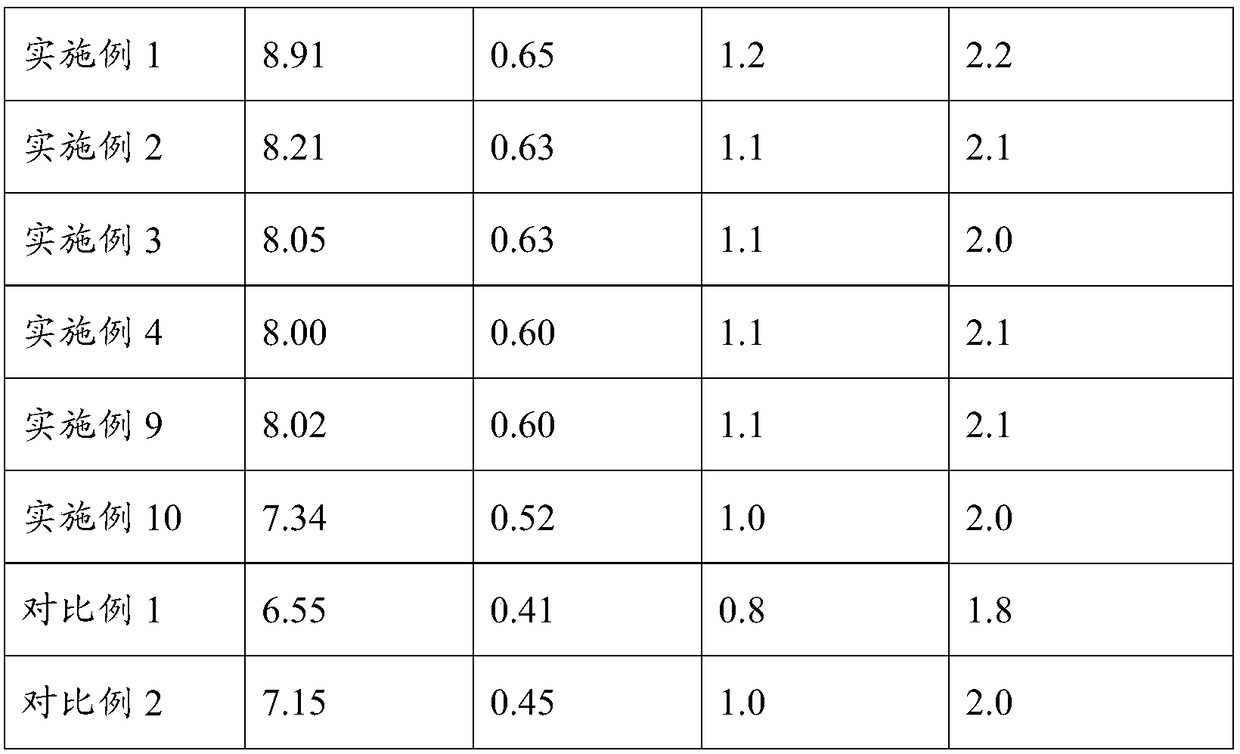

Embodiment 1

[0026] An environmentally friendly waterproof plugging material, made of the following raw materials in parts by weight: 50 parts of silicate, 15 parts of aluminate, 40 parts of redispersible rubber powder, 15 parts of quartz sand, 20 parts of paris plaster powder, 1 part of coagulant, 1 part of additive. The silicate is ordinary Portland cement, the aluminate is calcium aluminate, the retarder is citric acid, and the additive is modified graphene powder.

[0027] The modified graphene powder is prepared according to the following steps:

[0028] Step 1, weigh each raw material component according to the following mass ratio: calcium carbonate 1g, ammonium persulfate 0.2g, graphene powder 10g, water to 1L;

[0029] Step 2, mix the weighed calcium carbonate, water, and graphene powder, react at 85°C for 0.5h under stirring, then add the weighed ammonium persulfate, reflux in a water bath at 95°C for 20min, cool to room temperature, filter, and dry Dry solid to obtain modified...

Embodiment 2

[0036] An environment-friendly waterproof plugging material, which is made of the following raw materials in parts by weight: 100 parts of silicate, 10 parts of aluminate, 10 parts of redispersible rubber powder, 10 parts of quartz sand, 15 parts of paris plaster powder, 10 parts of coagulant, 10 parts of additives. The silicate is ordinary Portland cement, the aluminate is aluminate cement, the retarder is tartaric acid, and the additive is graphene powder.

Embodiment 3

[0038] An environment-friendly waterproof plugging material, which is made of the following raw materials in parts by weight: 80 parts of silicate, 35 parts of aluminate, 35 parts of redispersible rubber powder, 0.5 part of quartz sand, 5 parts of plaster powder, slow 8 parts of coagulant, 5 parts of additive. The silicate is ordinary Portland cement, the aluminate is calcium aluminate, the retarder is citric acid, and the additive is a commercially available cement-based permeable crystalline waterproof material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com