PLA/PBAT (Polylactic Acid/Poly(Butylene adipate-Co-Terephthalate) blending modified biodegradable resin prepared with chain extender and preparation method thereof

A biodegradable resin, blending and modification technology, applied in the field of degradable plastics, can solve the problems of inability to directly blown into film products, poor mechanical properties of resin, viscosity heat loss, etc., to achieve superior mechanical properties, impact resistance and Improvement of tear performance and improvement of resin viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

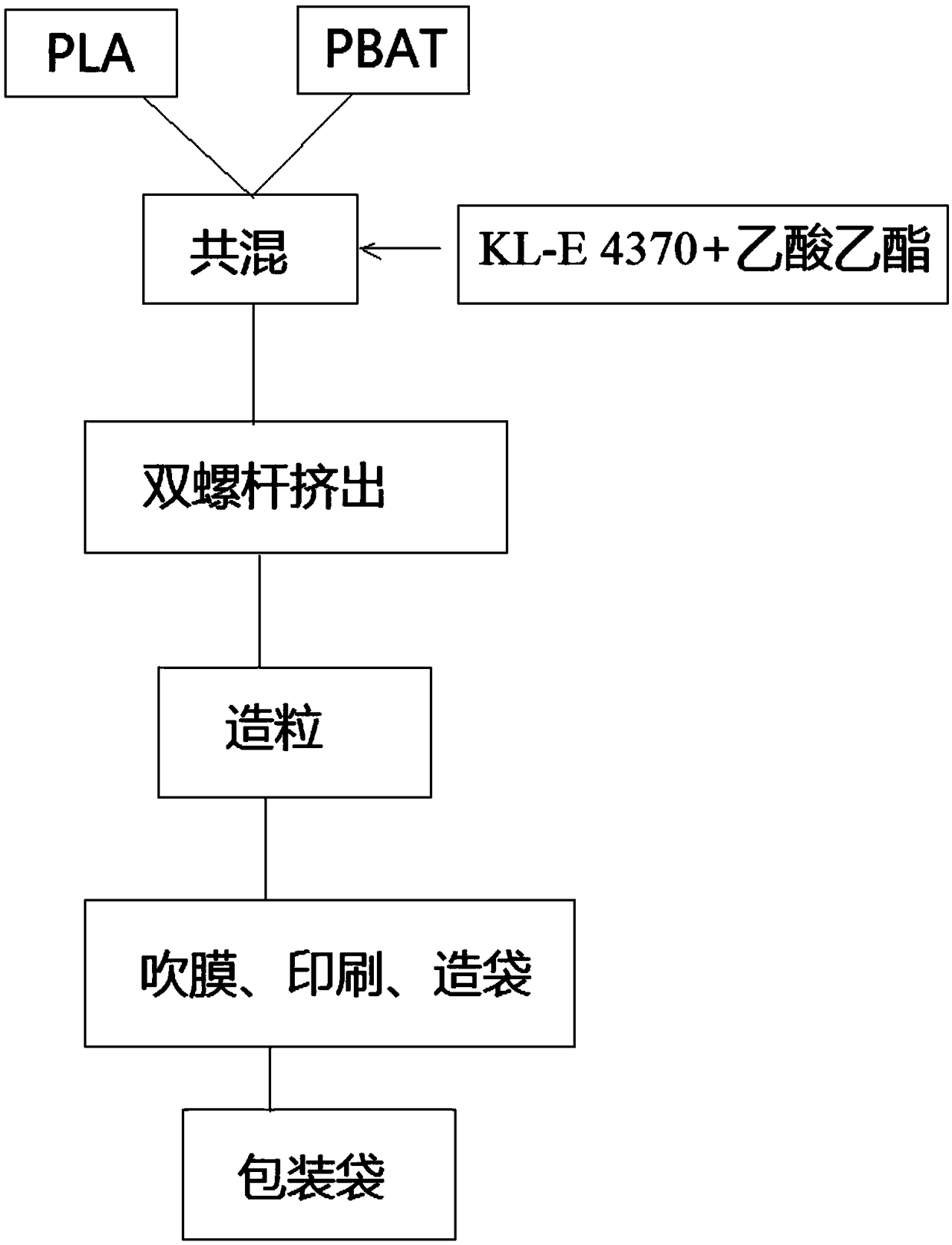

[0029] This adopts chain extender to prepare the method for PLA / PBAT blending modified biodegradable resin, and its steps comprise:

[0030] (1) Add 0.8% of the chain extender KL-E 4370 (Shanxi Research Institute of Chemical Industry) to double the mass of ethyl acetate solution, stir to dissolve it;

[0031] (2), weigh and mix the dried PLA granules and PBAT granules, and spray the solution obtained in step (1) on the surface of the mixed granules by spraying, wherein 20 parts of PLA are 4032D from American Nature Works, and 80 parts of PBAT are from Guangzhou Kingfa Science and Technology Co., Ltd. 1024, KL-E 4370 0.8% share;

[0032] (3), the mixed particles are sent into the twin-screw extrusion granulator, and through extrusion, air cooling, drawing, and cold cutting, PLA / PBAT blended modified biodegradable resin particles are made, wherein the temperature of the twin-screw extrusion The temperature is 130-180°C, the screw rotation speed is 350-400r / min, and the die head...

Embodiment 2

[0036] This adopts chain extender to prepare the method for PLA / PBAT blending modified biodegradable resin, and its steps comprise:

[0037] (1) Add 0.8% of the chain extender KL-E 4370 (Shanxi Research Institute of Chemical Industry) to double the mass of ethyl acetate solution, stir to dissolve it;

[0038] (2), weigh and mix the dried PLA granules and PBAT granules, and spray the solution obtained in step (1) on the surface of the mixed granules by spraying, wherein 10 parts of PLA are 4032D from American Nature Works, and 90 parts of PBAT are from Guangzhou 1024 of Kingfa Technology Co., Ltd., KL-E 4370 0.8%;

[0039] (3), the mixed particles are sent into the twin-screw extrusion granulator, and through extrusion, air cooling, drawing, and cold cutting, PLA / PBAT blended modified biodegradable resin particles are made, and the temperature of the twin-screw extrusion is The temperature is 160-180°C, the screw rotation speed is 350-400r / min, and the die head pressure is 3-5...

Embodiment 3

[0043] This adopts chain extender to prepare the method for PLA / PBAT blending modified biodegradable resin, and its steps comprise:

[0044] (1) Add the chain extender KL-E 4370 (Shanxi Research Institute of Chemical Industry) into the ethyl acetate solution of double the mass, stir to dissolve it;

[0045] (2), weigh and mix the dried PLA particles and PBAT particles, and spray the solution obtained in step (1) on the surface of the mixed particles by spraying, wherein 40 parts of PLA are 4032D from Nature Works of the United States, and 60 parts of PBAT are from Guangzhou 1024 of Kingfa Technology Co., Ltd., KL-E 4370 0.8%;

[0046] (3), the mixed particles are sent into the twin-screw extrusion granulator, and through extrusion, air cooling, drawing, and cold cutting, PLA / PBAT blended modified biodegradable resin particles are made, and the temperature of the twin-screw extrusion is The temperature is 130-180°C, the screw rotation speed is 350-400r / min, and the die head pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow rate | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com