A method for extracting tellurium from copper anode slime

A technology for anode slime and copper slag, which is applied in the direction of element selenium/tellurium and the improvement of process efficiency, can solve the problems of low tellurium recovery rate and complicated process, and achieve the effects of low cost, high metal recovery rate and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

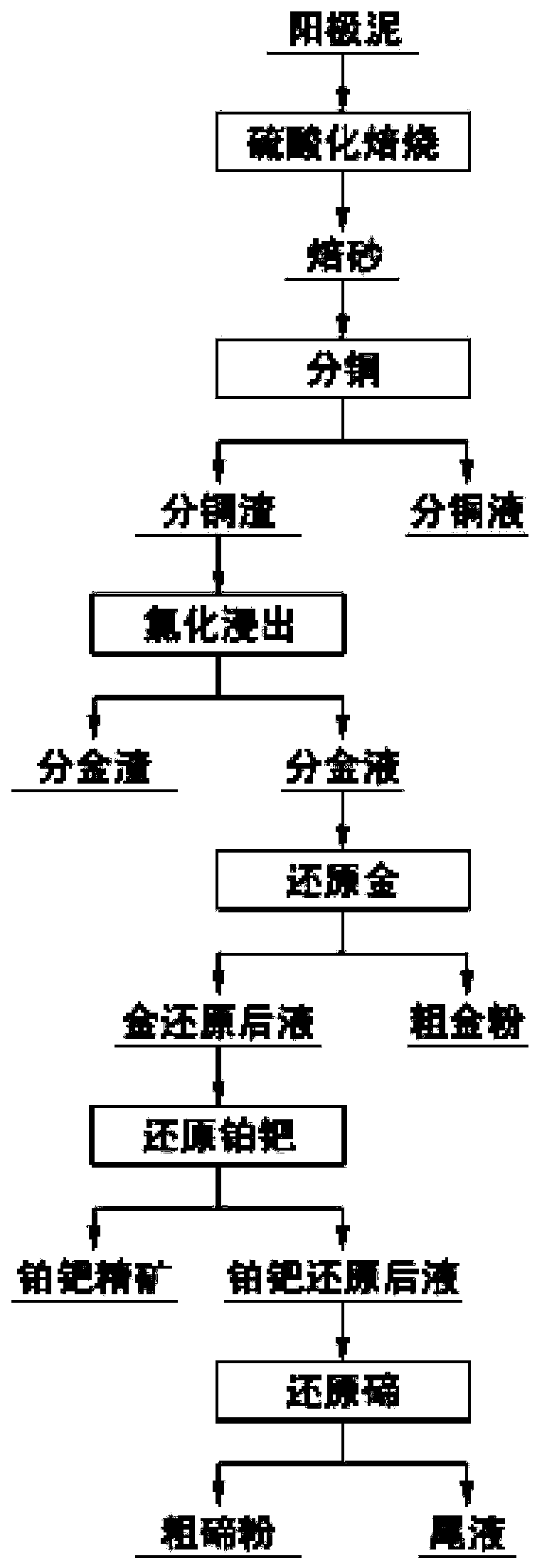

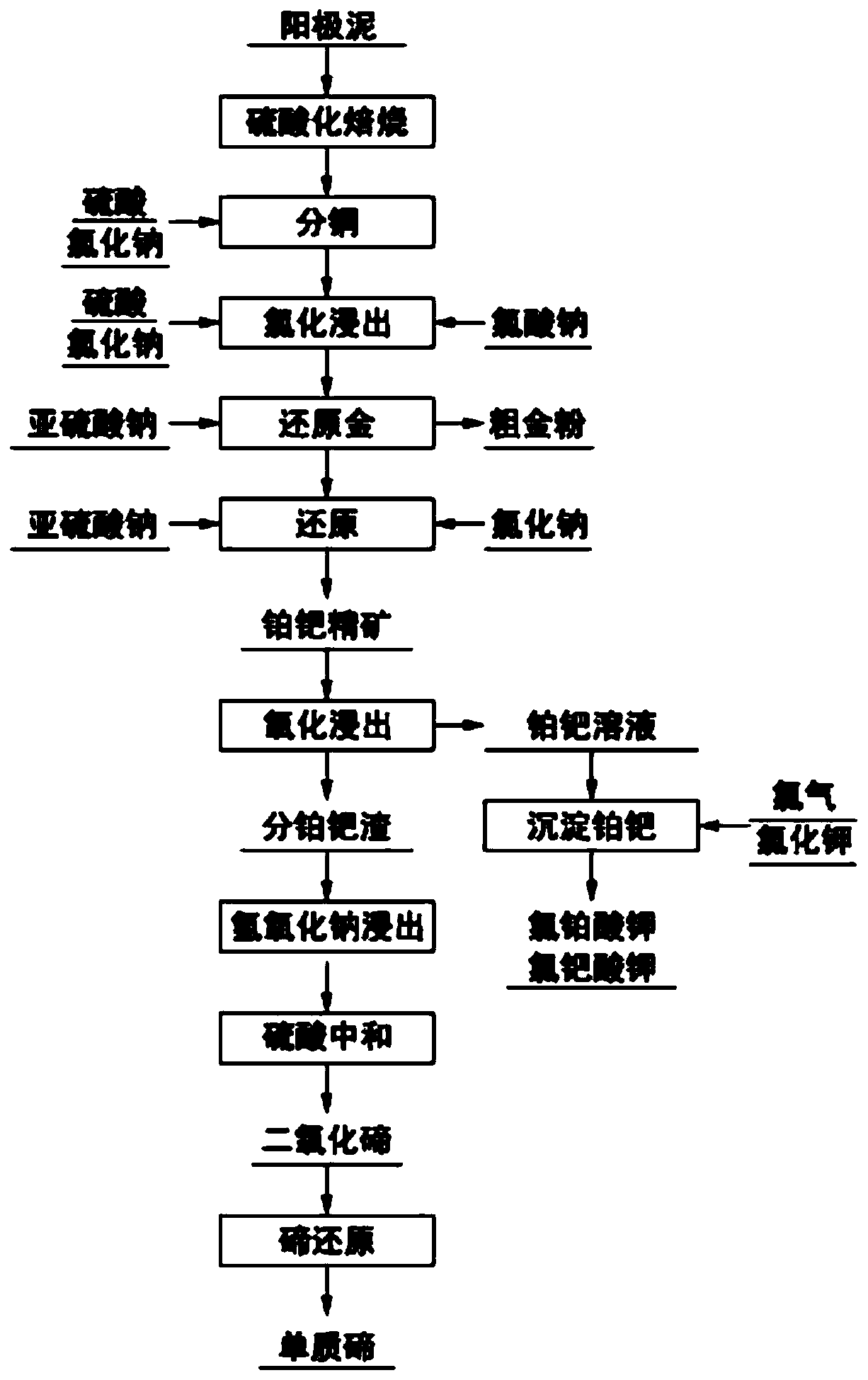

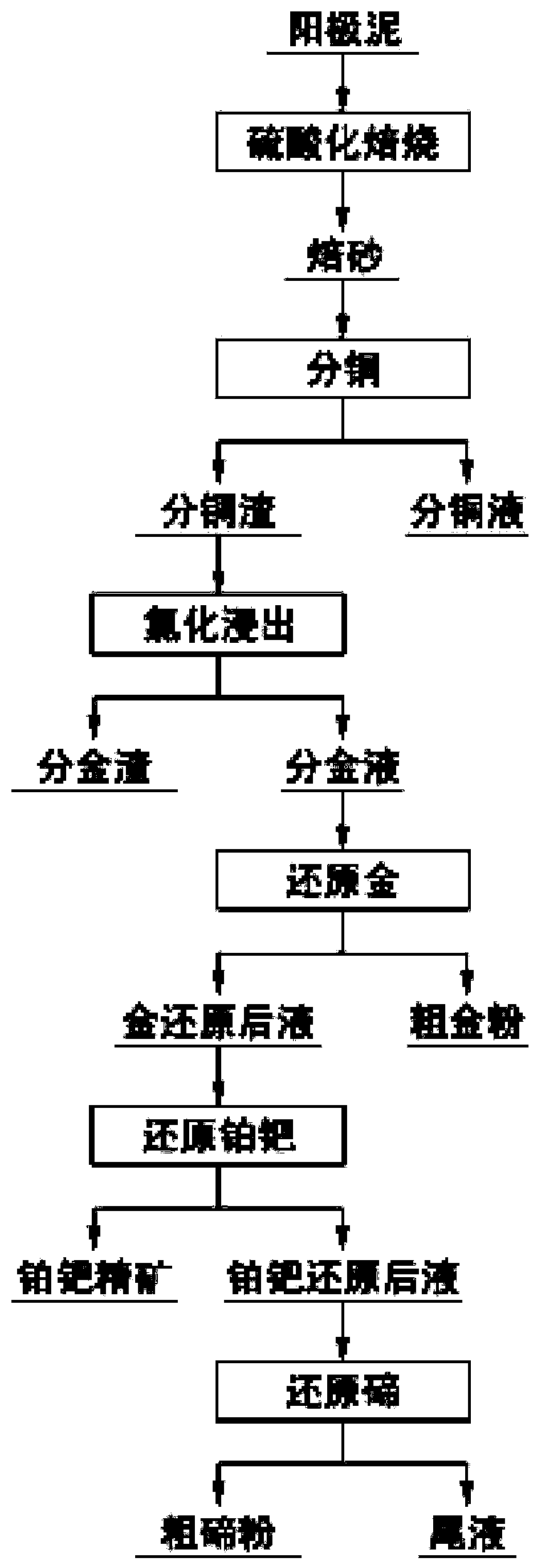

Method used

Image

Examples

Embodiment 1

[0039] A method for extracting tellurium from anode slime, comprising the steps of:

[0040] (1) The calcined sand obtained by sulphating and roasting the anode sludge is added to the sulfuric acid solution according to the solid-liquid ratio of the calcined sand and the sulfuric acid solution at 200g / L, and the leaching reaction is carried out at a temperature of 70°C for 120 minutes. After solid-liquid separation , to obtain copper-separating liquid and copper-separating slag. Wherein, the content of sulfuric acid in the sulfuric acid solution is 20g / L. After testing, the copper separation solution contained 37.37g / L copper, 7.37g / L silver, and 0.39g / L tellurium, and the copper separation slag contained 0.44wt% copper and 6.72wt% tellurium.

[0041] (2) Add the copper-separating slag into the mixed solution of hydrochloric acid and sulfuric acid according to the solid-to-liquid ratio of the copper-separating slag and the mixed solution at 200g / L, and carry out chlorination ...

Embodiment 2

[0046] A method for extracting tellurium from anode slime, comprising the steps of:

[0047] (1) The calcined sand obtained by sulphating and roasting the anode slime is added to the sulfuric acid solution for leaching reaction according to the solid-liquid ratio of the calcined sand and the sulfuric acid solution at 250g / L. After solid-liquid separation, the copper separation liquid and Divide copper slag. Wherein, the content of sulfuric acid in the sulfuric acid solution is 15g / L, the reaction temperature is 80°C, and the reaction time is 100min. After testing, the copper in the copper separation solution is 42.4g / L, the silver is 10.2g / L, and the tellurium is 0.47g / L. The copper separation slag contains 0.74wt% copper and 7.59wt% tellurium.

[0048] (2) Add the copper-separating slag into the mixed solution of hydrochloric acid and sulfuric acid according to the solid-liquid ratio of the copper-separating slag and the mixed solution at 150g / L, and use sodium chlorate as t...

Embodiment 3

[0053] A method for extracting tellurium from anode slime, comprising the steps of:

[0054] (1) The calcined sand obtained by sulphating and roasting the anode slime is added to the sulfuric acid solution for leaching reaction according to the solid-liquid ratio of the calcined sand and the sulfuric acid solution at 250g / L. After solid-liquid separation, the copper separation liquid and Divide copper slag. Wherein, the content of sulfuric acid in the sulfuric acid solution is 25g / L, the reaction temperature is 80°C, and the reaction time is 60min. After testing, the copper in the copper separation liquid is 55.2g / L, the silver is 11.25g / L, and the tellurium is 0.23g / L. In the copper separation slag, the copper is 0.81wt%, and the tellurium is 5.95wt%.

[0055] (2) Add the copper-separating slag into the mixed solution of hydrochloric acid and sulfuric acid according to the solid-liquid ratio of the copper-separating slag and the mixed solution at 250g / L, and use sodium chlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com