Centrifugal ultrafiltration sample handling device and use method thereof

A sample processing and centrifuge technology, which is applied in the direction of measuring devices, test sample preparation, sampling, etc., can solve the problems of low efficiency and slow dialysis speed, and achieve the effects of avoiding sample contamination, improving purity, and simple facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

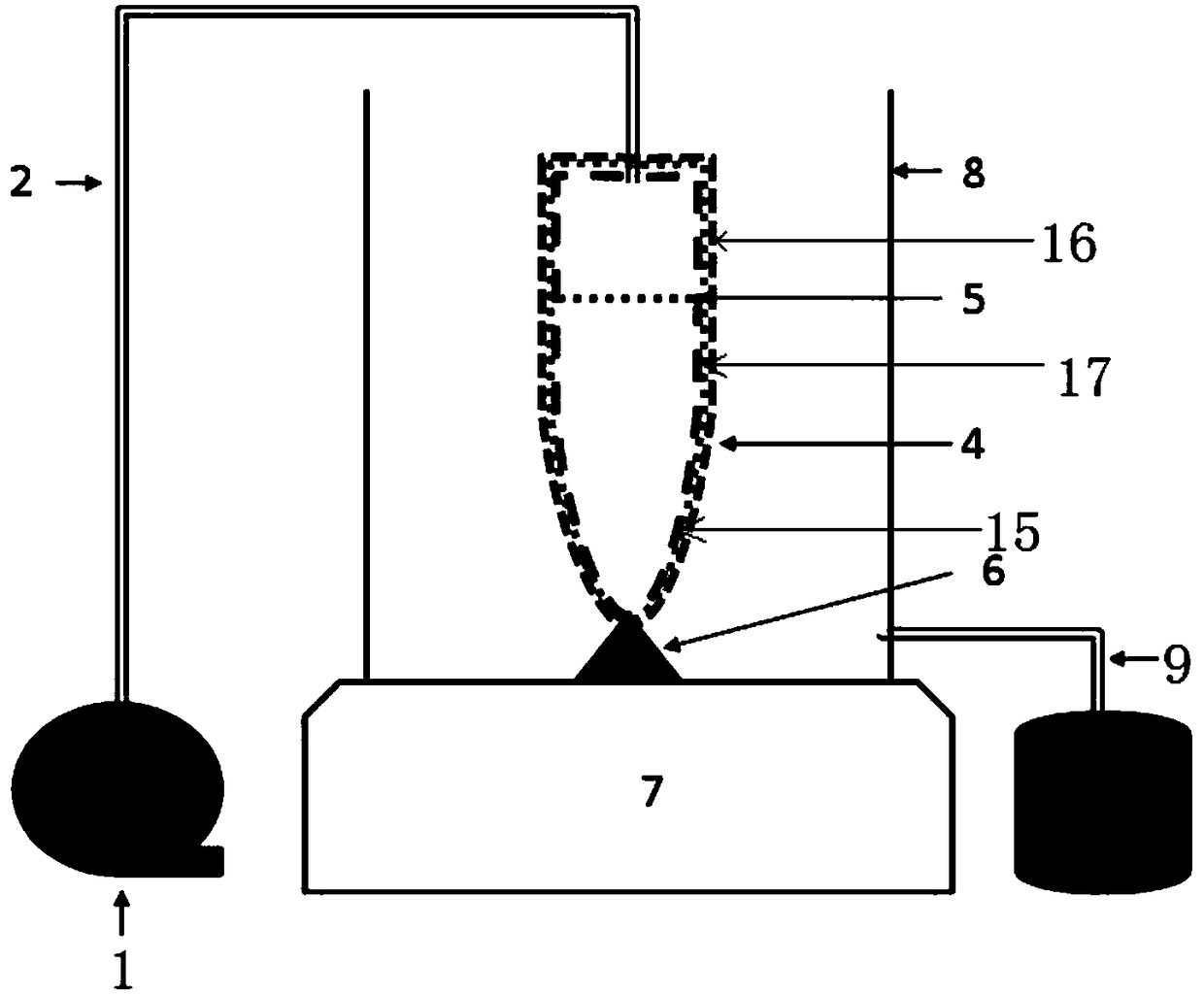

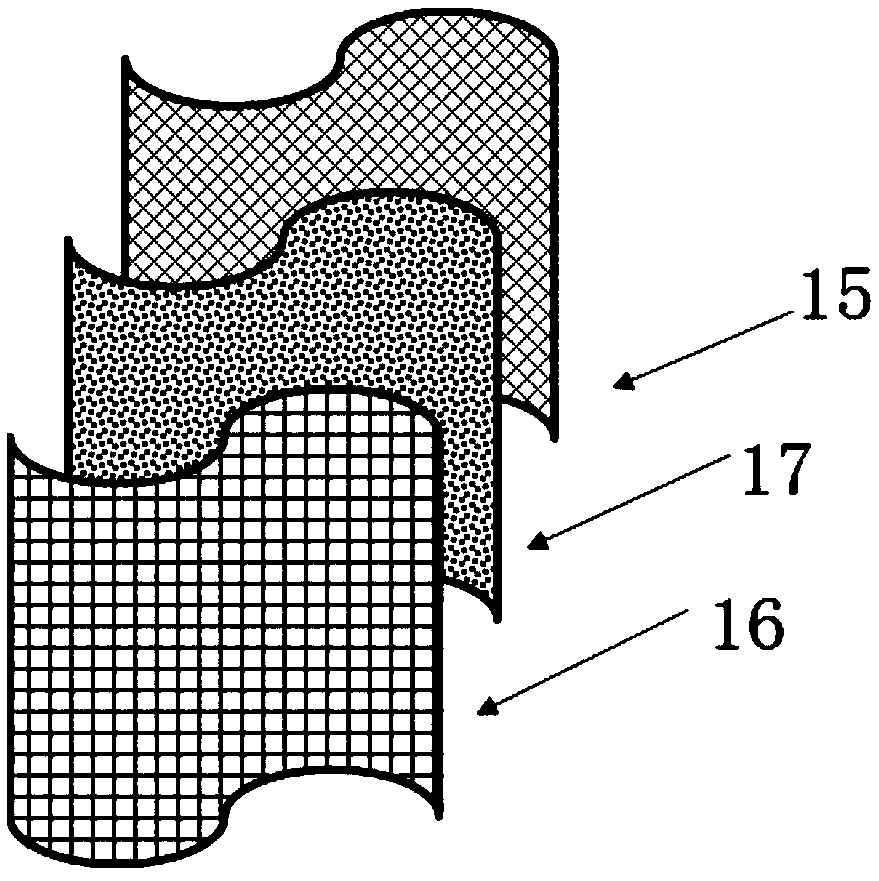

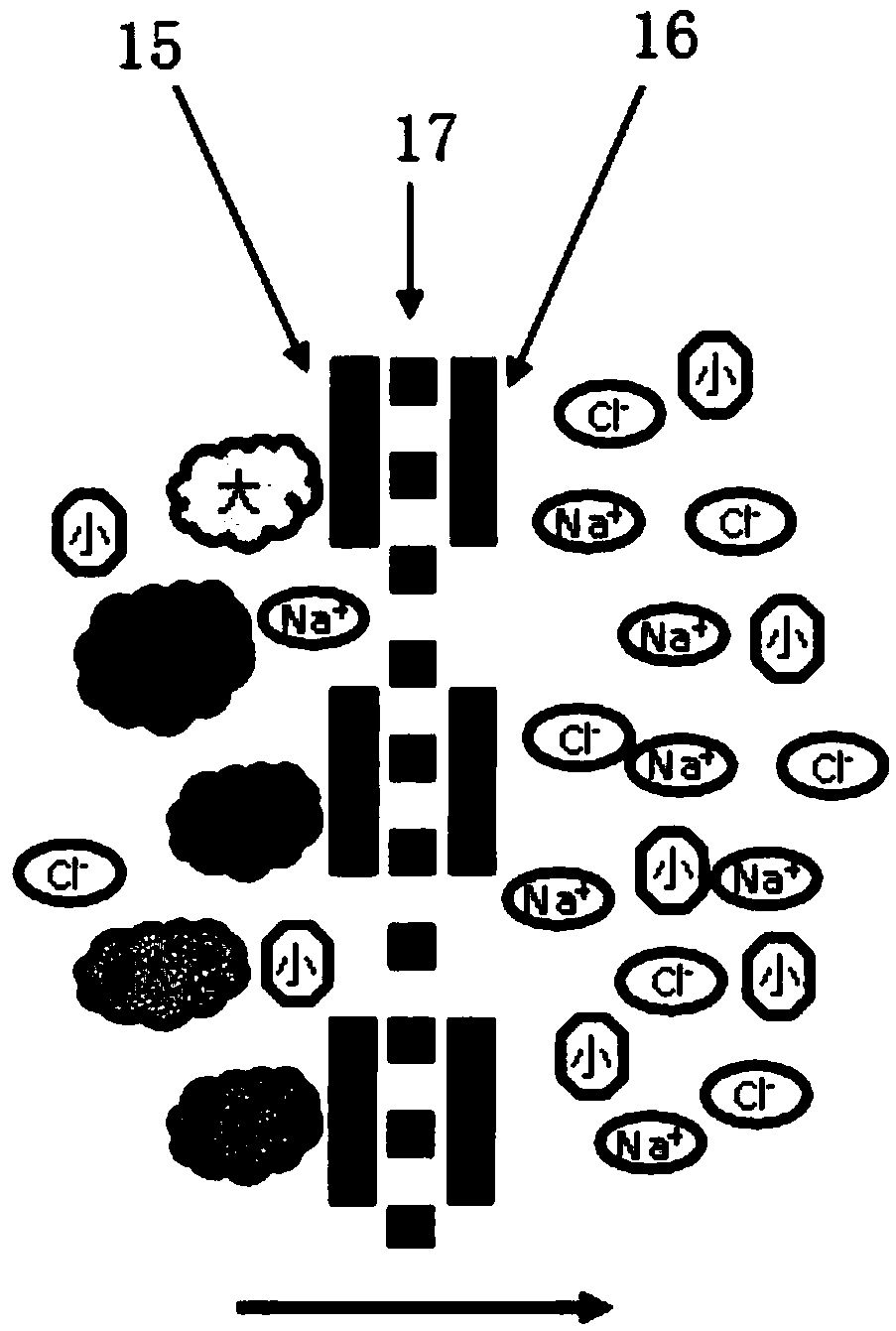

[0046] Such as Figure 4 As shown, the ultrafiltration rotor cup 4 of the centrifugal ultrafiltration sample processing device in the present embodiment is parabolic, with an inner diameter of 5 cm and a height of 15 cm; the ultrafiltration rotor cup 4 has a three-layer structure, such as figure 2 As shown, the inner clamping layer 15 is a mixed cellulose ester membrane with a pore diameter of 0.22 microns, the dialysis membrane layer 17 is a cellulose membrane with a molecular weight cut-off of 500 Da, and the outer clamping layer 16 is made of polytetrafluoroethylene with a pore diameter of 2 microns; One pump system 1 is A pump 13, B pump 14 binary constant flow pump, the maximum flow rate is 10ml / min; the centrifuge 7 can rotate forward or reverse, the maximum speed is 3000r / min; the solvent cup 8 is a round table type, the inner diameter of the upper bottom is 10cm, the inner diameter of the lower bottom is 18cm, and the height is 18cm. The round table type solvent cup 8...

Embodiment 2

[0056] Such as Figure 5 As shown, the ultrafiltration rotor 4 of the centrifugal ultrafiltration sample processing device in this embodiment is cylindrical, with an inner diameter of 55 cm and a height of 35 cm; the walls of the ultrafiltration rotor 4 are composed of 4 layers, and the inner holding layer 15 is an aperture. 10 micron polypropylene material, the dialysis membrane layer 17 is a polyethersulfone membrane with a molecular weight cut-off of 1kDa, the outer clamping layer 16 is made of polypropylene with a pore diameter of 2 microns, and the outer clamping layer 16 is made of polypropylene with a pore diameter of 1 mm. Both the first pump system 1 and the C pump 11 are constant flow pumps. The maximum rotational speed of the centrifuge 7 is 3000r / min; the circular truncated shell can reduce the splashing and splashing of the solvent during the centrifugation process. The device of the invention can retain substances with a molecular weight greater than 1kDa, and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com