Method for reducing content of organic volatile matter in polypropylene processing process

A technology of organic volatiles and processing, applied in the field of reducing the content of organic volatiles in the processing of polypropylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

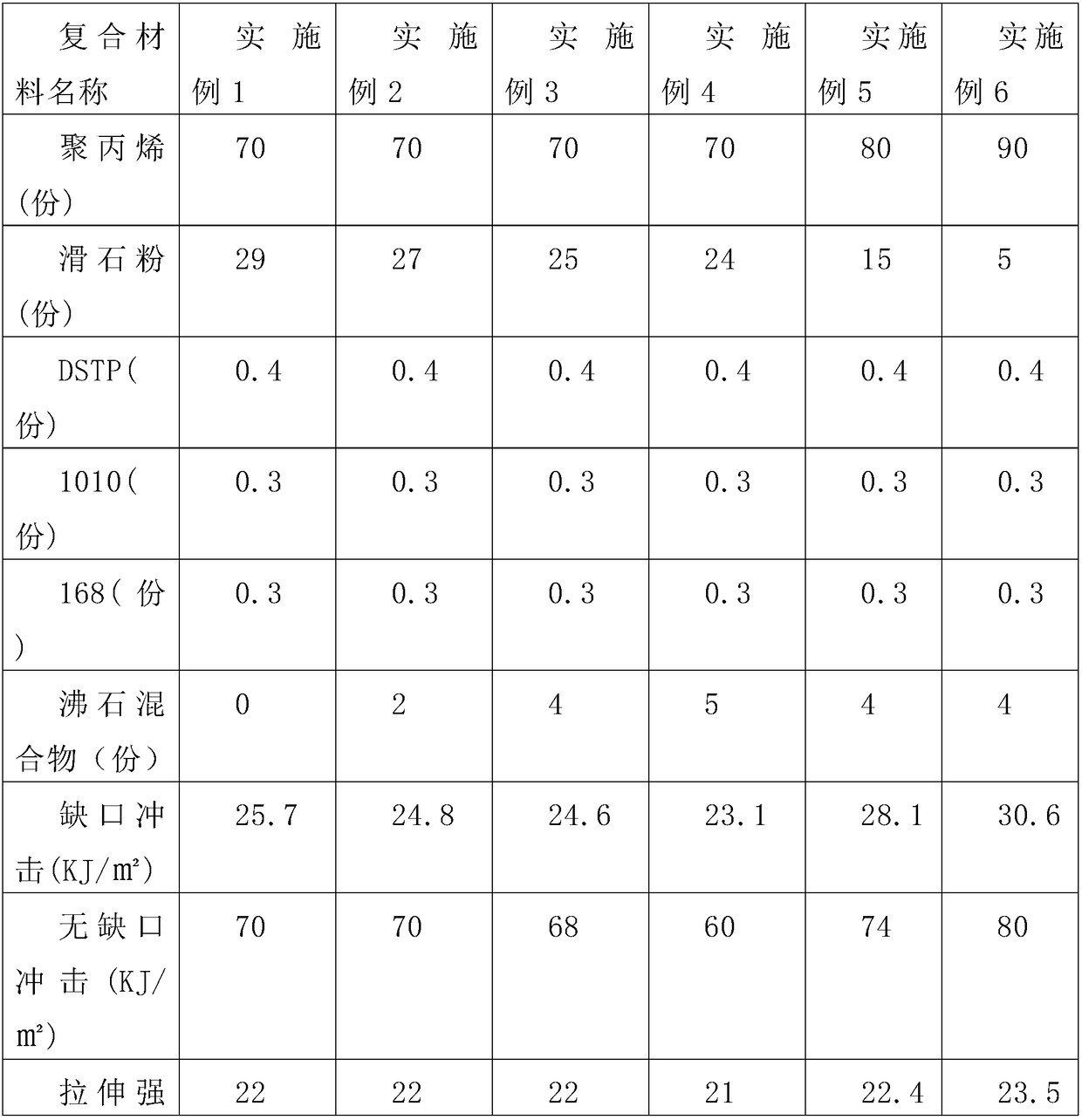

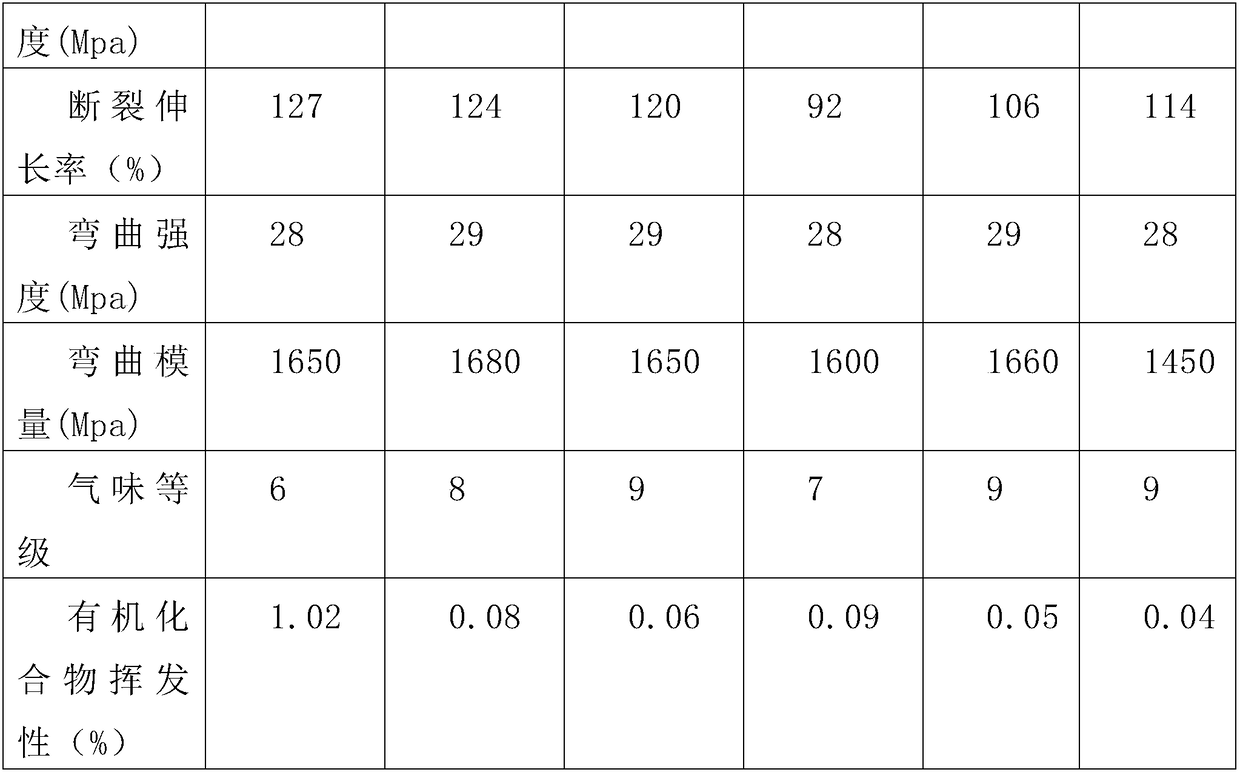

Examples

Embodiment 1

[0031] A. Take 70 parts of polypropylene, 29 parts of talcum powder, 0.4 parts of stabilizer DSTP, and 0.3 parts of antioxidants 1010 and 168.

[0032] B. Put the components described in step A into a 400-600r / min mixer and dry mix for 3-5 minutes; the temperature of the feeding section is controlled in the first zone; the mixed material is placed in a twin-screw extruder, After melting and plasticizing, extruding and granulating, the plasticizing section needs to go through five temperature ranges, and the temperatures are controlled in the second, third, fourth, fifth and sixth zones respectively. During the extrusion and granulation process, the processing The small molecules produced in the process are extracted, and the water or alcohol vapor and organic volatiles are extracted with a vacuum pump. The temperature of the vacuum section is controlled in four zones, which are the seventh zone, the eighth zone, the ninth zone and the tenth zone, thereby obtaining low odor. Ev...

Embodiment 2

[0034] A. Take 70 parts of polypropylene, 27 parts of talcum powder, 0.4 parts of stabilizer DSTP, 0.3 parts of antioxidants 1010 and 168, 2 parts of glycerin and water adsorbed by zeolite or a mixture of glycerin, water and alcohol adsorbed by zeolite.

[0035] B. Put the components described in step A into a 400-600r / min mixer and dry mix for 3-5 minutes; the temperature of the feeding section is controlled in the first zone; the mixed material is placed in a twin-screw extruder, After melting and plasticizing, extruding and granulating, the plasticizing section needs to go through five temperature ranges, and the temperatures are controlled in the second, third, fourth, fifth and sixth zones respectively. During the extrusion and granulation process, the processing The small molecules produced in the process are extracted, and the water or alcohol vapor and organic volatiles are extracted with a vacuum pump. The temperature of the vacuum section is controlled in four zones, ...

Embodiment 3

[0037] A. Take 70 parts of polypropylene, 25 parts of talcum powder, 0.4 parts of stabilizer DSTP, 0.3 parts of antioxidants 1010 and 168, 4 parts of glycerin and water adsorbed by zeolite or a mixture of glycerin, water and alcohol adsorbed by zeolite.

[0038] B. Put the components described in step A into a 400-600r / min mixer and dry mix for 3-5 minutes; the temperature of the feeding section is controlled in the first zone; the mixed material is placed in a twin-screw extruder, After melting and plasticizing, extruding and granulating, the plasticizing section needs to go through five temperature ranges, and the temperatures are controlled in the second, third, fourth, fifth and sixth zones respectively. During the extrusion and granulation process, the processing The small molecules produced in the process are extracted, and the water or alcohol vapor and organic volatiles are extracted with a vacuum pump. The temperature of the vacuum section is controlled in four zones, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com