Combined process taking gramineous plants as raw materials

A technology of plant raw materials and grasses, applied in the field of combined technology, can solve the problems of not adapting to changes in the paper consumption market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

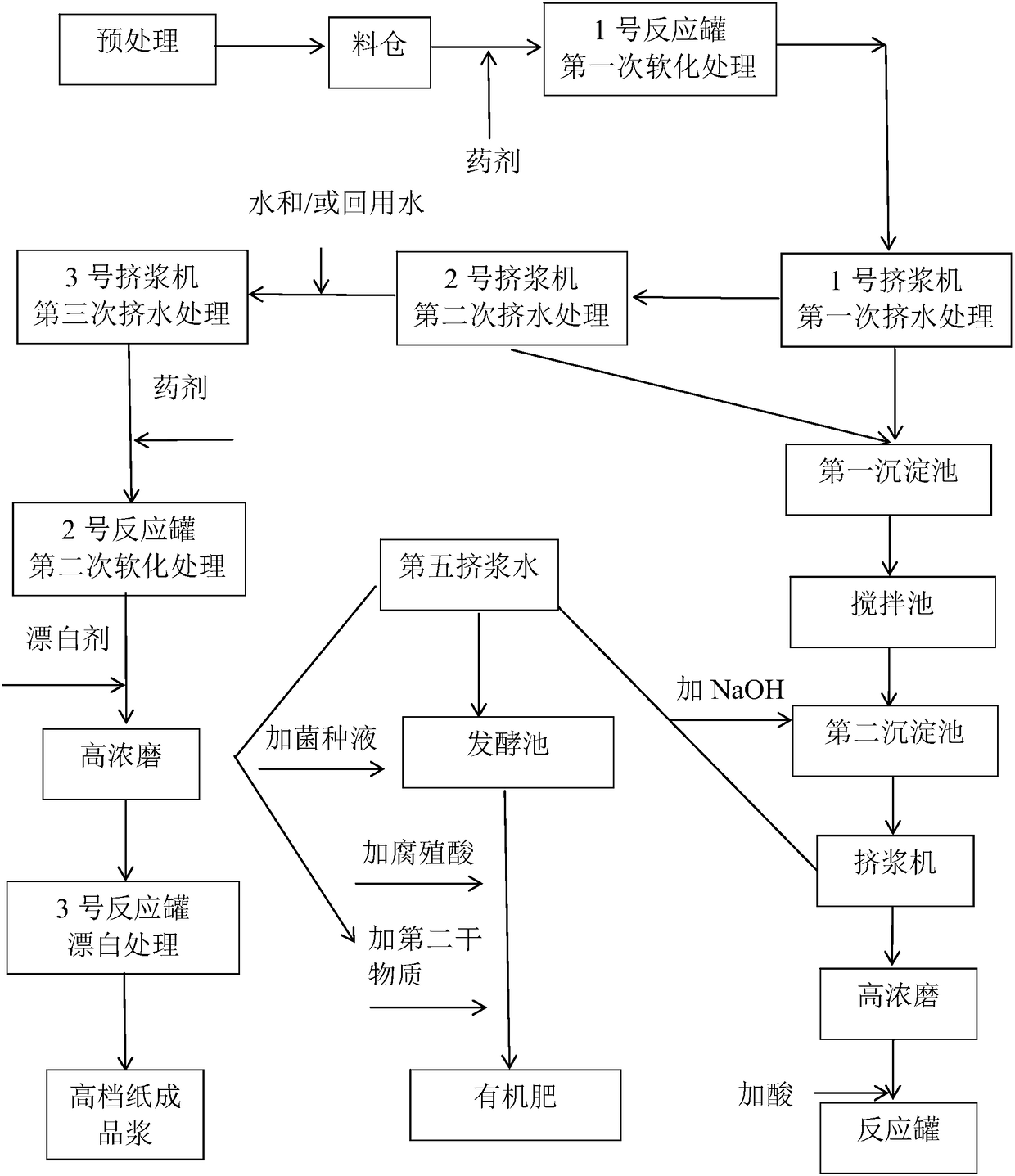

Method used

Image

Examples

Embodiment 1

[0202] 1. Prepare high-grade paper from grasses——rice straw

[0203] Select dry straw, remove impurities and dust, and crush it. There is a trumpet-shaped dust removal device at the entrance of the pulverizer, and there are two trumpet-shaped dust removal devices next to the screw rod at the feeding port of the silo. The crushing is to crush the raw materials. into 2-3 cm sections, sieved and separated to obtain pulping raw materials, and stored in the silo;

[0204] Add 1 ton of the above-mentioned pulping raw material - straw into the No. 1 reaction tank by means of screw feeding, and use the same feeding method to add 3 tons of clean water and / or recycled water, 62kg of hydrogen peroxide and 62kg of sodium hydroxide At the same time, add it to the No. 1 reaction tank, stir evenly, and keep the pH of the mixed material in the No. 1 reaction tank greater than or equal to 12; due to the self-heating phenomenon of the softening reaction, when the reaction starts, the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tightness | aaaaa | aaaaa |

| Burst index | aaaaa | aaaaa |

| Whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com