Processing method of high-anthocyanin-content concentrated red raspberry juice

A technology for concentrating fruit juice and red raspberry fruit, applied in food processing, food science, food preservation and other directions, can solve the problems of easy thermal degradation of anthocyanins and poor product quality, and achieve good sensory quality and high retention rate of products. , beneficial to the effect of sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

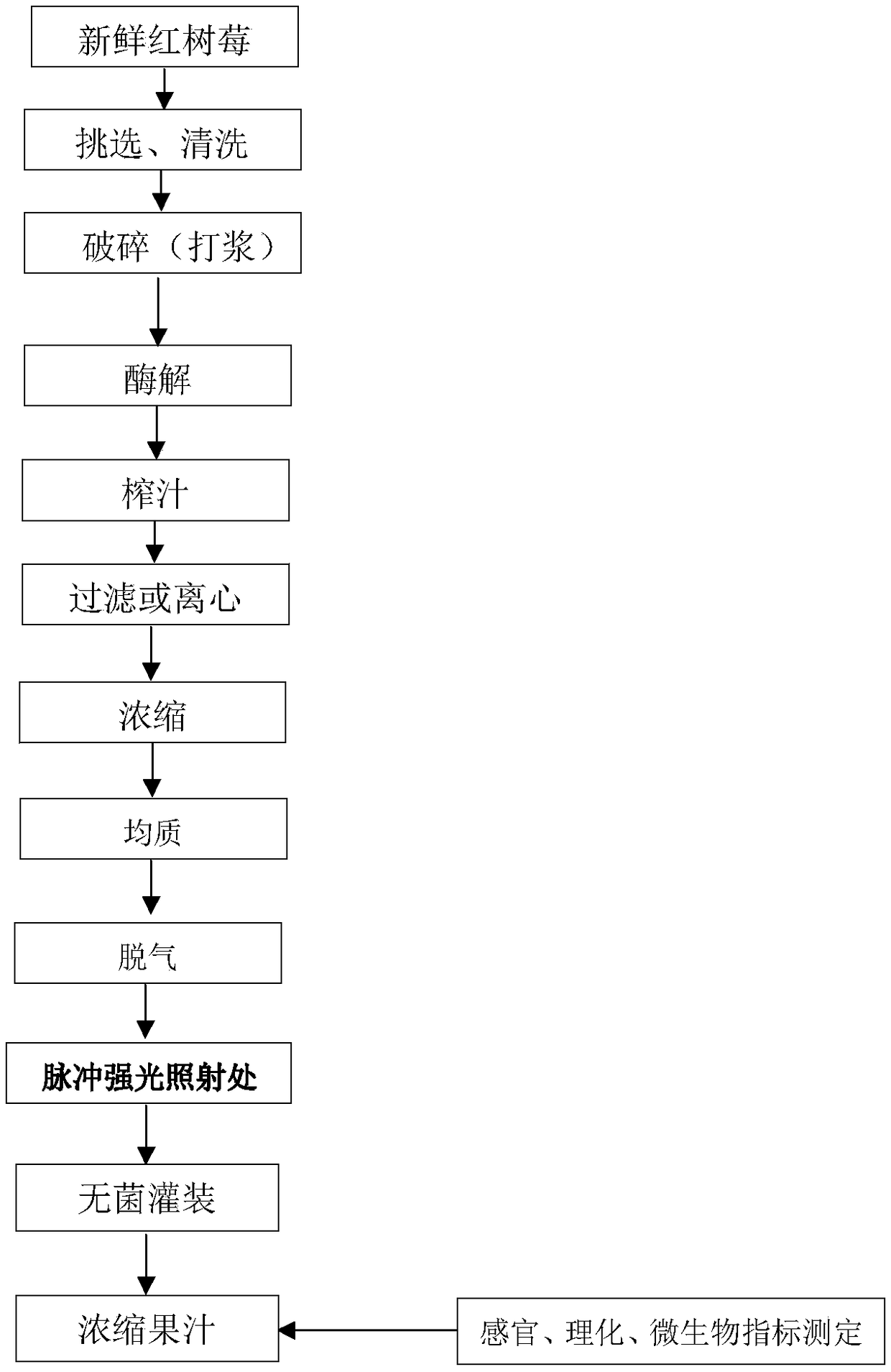

Method used

Image

Examples

Embodiment 1

[0033] (1) Sorting of raw materials: the red raspberry fruit is required to be fresh, mildew, disease and insect damage, immature fruit and miscellaneous fruit are removed, eight or nine mature fruits are used, and the fruit stems are removed, and 2.0 kg of red raspberry fruit is selected.

[0034] (2) Cleaning: Soak and wash with pure water for 1.5 minutes to remove mud, sand, sundries, residual pesticides and microorganisms on the surface of red raspberries. Red raspberries have a soft texture and are washed in small batches to prevent mechanical damage.

[0035] (3) Crushing (beating): add 1 kg of pure water to the washed fruit, and use a shear emulsification mixer (JRJ300-SH, Shanghai Huxie) for 3 minutes to crush and beat.

[0036] (4) Enzyme hydrolysis treatment: red raspberries generally contain more pectin. If pectinase is not used, the fruit pulp obtained after the fruit is broken will be thick, with little free-flowing juice, and it will be difficult to squeeze the j...

Embodiment 2

[0065] Carry out following steps according to operation method and detection method among the embodiment 1:

[0066] 2kg of fresh red raspberries→selection, removal of impurities→cleaning→add 1.5kg of pure water, crush and beat for 4min→add pectinase with 0.03% pulp weight, enzymolysis at 45℃ for 2h, pH=3.0→juicing→4000r / Centrifuge for 8 min→concentrate the clear liquid to 1 / 4 of the original volume in vacuum at 45℃→homogenize at 30MPa→degas by ultrasonic for 4min→irradiate with pulsed strong light for 45s→aseptic filling→new concentrated red raspberry juice→storage at 25℃ for 2 weeks After detection.

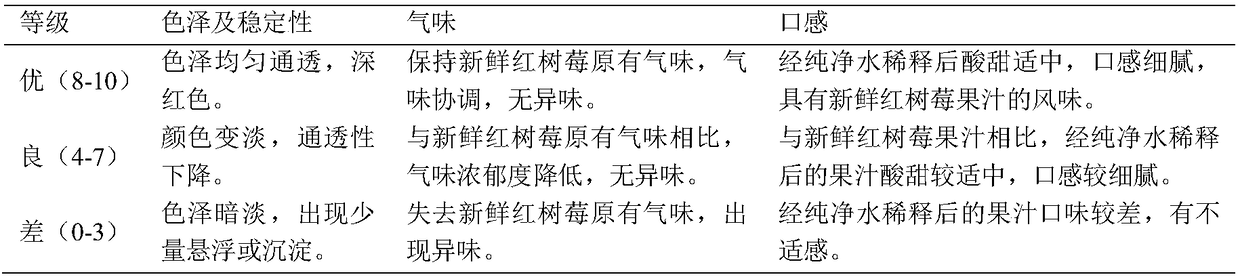

[0067] After testing, the soluble solid content was 29.6±1.4%, the total anthocyanin content was 261.2±12μg / mL, the VC content was 0.28±0.01mg / mL, the total number of bacteria was 72CFU / mL, the coliform group was 3CFU / mL, and no pathogenic bacteria Detected, the sensory score is 26.2±1.3, which belongs to the excellent level.

Embodiment 3

[0069] Carry out following steps according to operation method and detection method among the embodiment 1:

[0070] 2kg of fresh red raspberries→selection, removal of impurities→cleaning→add 2kg of pure water, crush and beat for 5min→add pectinase with 0.05% pulp weight, enzymolysis at 50℃ for 1h, pH=3.5→juicing→4000r / min Centrifuge for 10min→concentrate the clear liquid to 1 / 5 of its original volume in vacuum at 45℃→homogenize at 40MPa→degas by ultrasonic for 5min→irradiate with pulsed strong light for 60s→aseptic filling→new concentrated red raspberry juice→storage at 25℃ for 2 weeks detection.

[0071] After testing, the soluble solid content was 26.5±1.4%, the total anthocyanin content was 247±11μg / mL, the VC content was 0.28±0.01mg / mL, the total number of bacteria was 63CFU / mL, the coliform group was 3CFU / mL, and no pathogenic bacteria Detected, the sensory score is 28.6±1.3, belonging to the excellent level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com