Preparation device and preparation method for DHA algal oil HIPE (high internal phase emulsion) gel

A technology of high internal phase emulsion and preparation device, which is applied in the field of preparation device of DHA algae oil high internal phase emulsion gel, can solve the problem that the high internal phase emulsion has large particle size, instability, and cannot protect embedded substances well, etc. problem, to achieve the effect of improving oxidation resistance and stability, increasing load, and having a more interesting appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

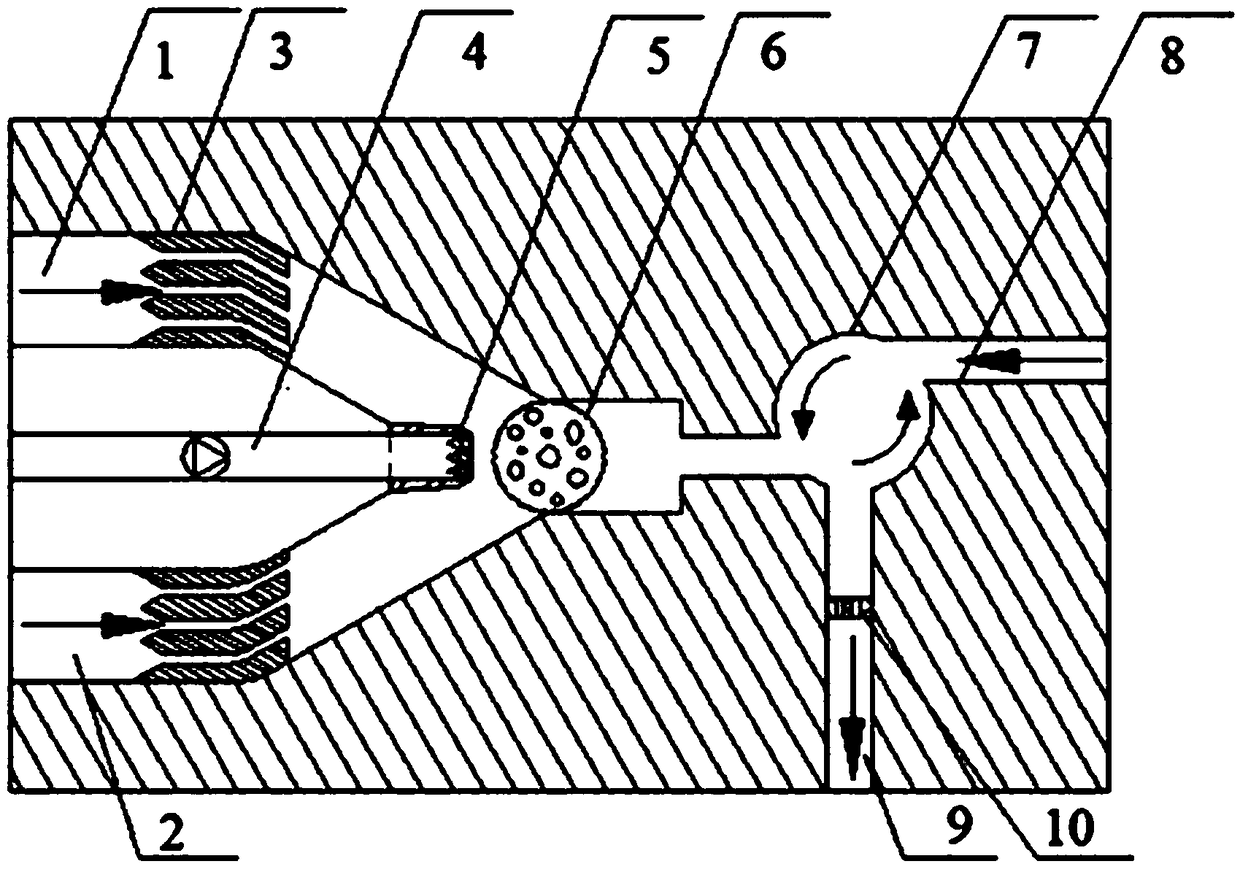

[0019] A preparation device for DHA algae oil high internal phase emulsion gel, comprising first and second sampling pipelines 1, 2, hard impact member 3, gas passage 4, gas extrusion valve 5, sphere collision chamber 6, Mixing cavity 7, feed pipeline 8 and discharge pipeline 9; The sampling ends of described first and second sampling pipelines 1 and 2 are respectively used to prepare the oil phase and water phase of high internal phase emulsion to enter and discharge The ends are connected and combined to form a "V"-shaped structure, the hard impact member 3 is arranged inside the first and second sampling pipes 1, 2; the inlet end of the gas channel 4 is used for the inert gas to enter , the gas outlet is provided with a gas squeeze valve 5 for dividing the inert gas into several streams of air flow; one end of the sphere colliding cavity 6 is connected with the sample outlets of the first and second sample injection pipes 1 and 2 and the gas outlet respectively. The gas out...

Embodiment 1

[0025] Weighing and dissolving raw materials: Weigh 10kg of whey protein isolate powder and dissolve it in 200L of drinking water to obtain a whey protein isolate solution. For the denatured protein solution, 1 kg of gluconolactone was weighed and dissolved in the heat-denatured protein solution to obtain an aqueous phase material. Weigh 20kg of sodium alginate and dissolve it in 1000L of drinking water to obtain sodium alginate solution.

[0026] Preparation of high internal phase emulsion: open the gas channel 4 and continuously feed inert gas, and simultaneously introduce the water phase material, 1800L DHA algae oil and sodium alginate solution into the high-pressure micro-jet granulator with a high pressure of 40MPa, and the water phase material is fed by the second The pipeline 2 is introduced, the DHA algae oil is introduced through the first sampling pipeline 1, and the sodium alginate solution is introduced through the feed pipeline 8; the water phase material, algae ...

Embodiment 2

[0029] Weighing and dissolving raw materials: Weigh 10kg of whey protein isolate powder and dissolve it in 200L of drinking water to obtain a whey protein isolate solution. For the denatured protein solution, weigh 1kg of gluconolactone and dissolve it in the heat-denatured protein solution to obtain a water phase material; weigh 20kg of sodium alginate and dissolve it in 1000L of drinking water to obtain a sodium alginate solution.

[0030] Preparation of high internal phase emulsion: Mix the water phase material and 1800L DHA algae oil together, disperse the mixed solution after 15000rpm and 2min high-speed shearing, and process the dispersed emulsion through traditional high-pressure micro-fluidic treatment to obtain DHA high internal phase For the emulsion, the prepared high internal phase emulsion is mixed evenly with the sodium alginate solution.

[0031] Preparation of gel microbeads: drop the emulsion uniformly mixed with sodium alginate solution into calcium chloride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com