Red mud treatment and aluminum oxide production method

An alumina and red mud technology, applied in the field of mineral processing, can solve the problems of narrow sintering temperature range, strict equipment requirements, low added value of products, etc., to avoid corrosion problems, turn waste into treasure without waste discharge, and reduce infrastructure investment. and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

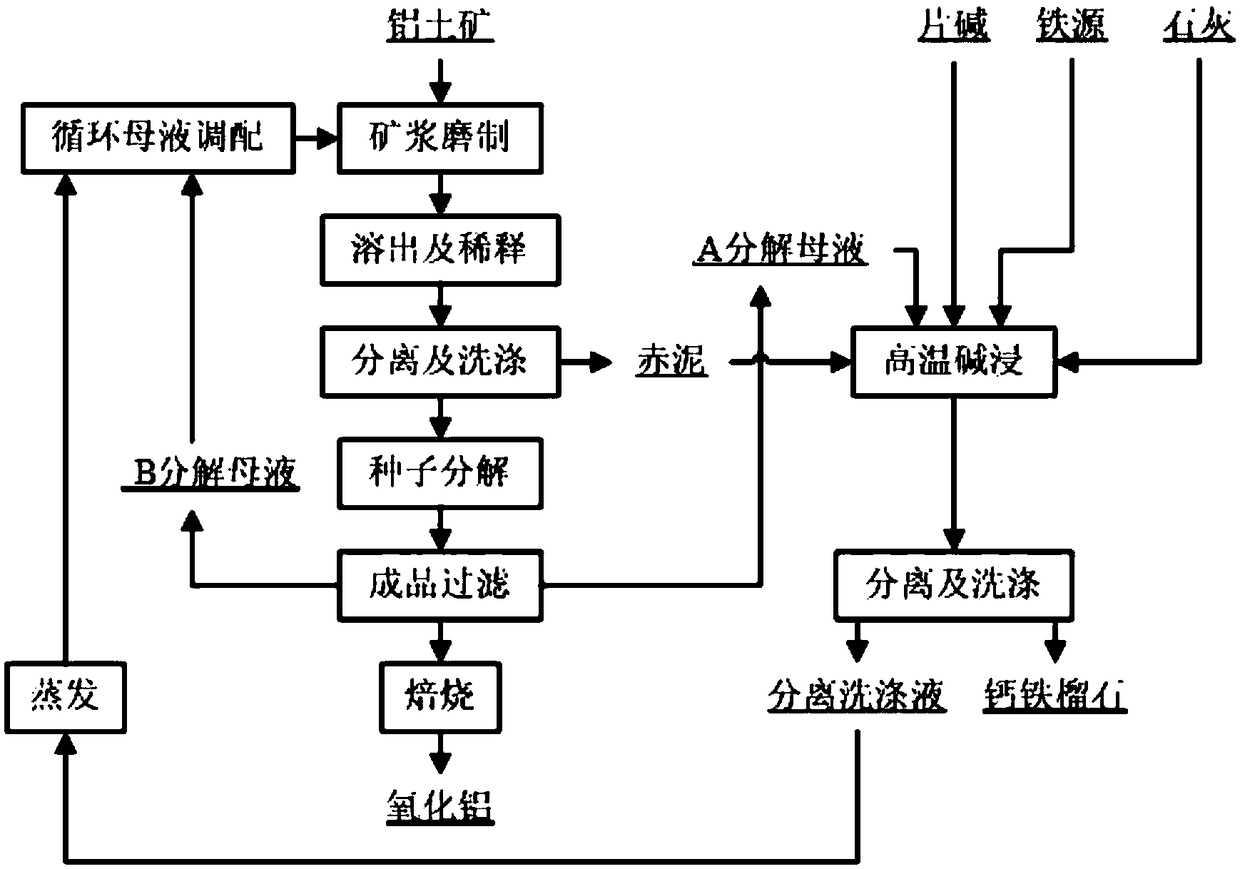

[0042] A method for alumina production, its process flow chart is as figure 1 shown, including the following steps:

[0043] (1) Take the Bayer method to decompose the mother liquor and red mud, the aluminum-silicon ratio in the red mud is 1.24, divide the Bayer method to decompose the mother liquor into two parts A and B, wherein, the A part is used for red mud treatment, and the B part is used for The specific steps of alumina production and red mud treatment are:

[0044] Mix the mother liquid A decomposed by the Bayer process with the red mud evenly, add iron source, caustic soda and lime to make the material to be leached, wherein:

[0045] The amount of the decomposed mother liquor A added is calculated as 3 according to the mass ratio of the liquid to the solid in the material to be leached;

[0046] The added amount of iron source is Fe 2 o 3 Gauge, Fe 2 o 3 The amount of addition is based on the amount of Fe in the material to be leached 2 o 3 with Al 2 o 3 Th...

Embodiment 2

[0058] A method for alumina production, its process flow chart is as figure 1 shown, including the following steps:

[0059] (1) Take the Bayer method to decompose the mother liquor and red mud, the aluminum-silicon ratio in the red mud is 1.24, divide the Bayer method to decompose the mother liquor into two parts A and B, wherein, the A part is used for red mud treatment, and the B part is used for Alumina production, the specific steps of red mud treatment are: mix the Bayer decomposition mother liquor A with red mud evenly, add iron source, caustic soda and lime to make the material to be leached, of which:

[0060] The amount of the decomposed mother liquor A added is calculated as 3 according to the mass ratio of the liquid to the solid in the material to be leached;

[0061] The added amount of iron source is Fe 2 o 3 Gauge, Fe 2 o 3 The amount of addition is based on the amount of Fe in the material to be leached 2 o 3 with Al 2 o 3 The mol ratio is 0.2, and th...

Embodiment 3

[0073] A method for alumina production, its process flow chart is as figure 1 shown, including the following steps:

[0074] (1) Take the Bayer method to decompose the mother liquor and red mud, the aluminum-silicon ratio in the red mud is 1.2, divide the Bayer method to decompose the mother liquor into two parts A and B, wherein, the A part is used for the red mud treatment, and the B part is used for Alumina production, the specific steps of red mud treatment are: mix the Bayer decomposition mother liquor A with red mud evenly, add iron source, caustic soda and lime to make the material to be leached, of which:

[0075] The added amount of the decomposed mother liquor A is 5 according to the mass ratio of the liquid to the solid in the material to be leached;

[0076] The added amount of iron source is Fe 2 o 3 Gauge, Fe 2 o 3 The amount of addition is based on the amount of Fe in the material to be leached 2 o 3 with Al 2 o 3 The molar ratio is 0.5, and the iron so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com