Microporous ceramic, ceramic heating element and preparation method and application thereof

A ceramic heating element and microporous ceramic technology, which is applied in the field of ceramic materials, can solve the problems of low air porosity, affecting the taste, and microporous ceramics are easy to lose powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

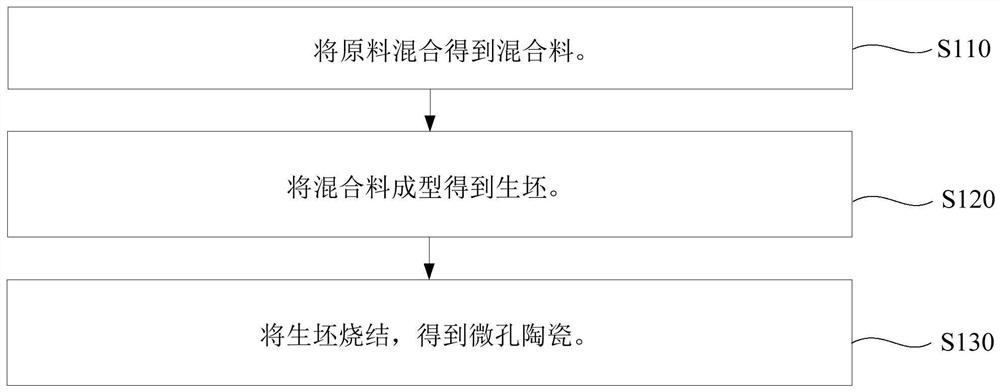

[0022] Such as figure 1 Shown, the preparation method of the microporous ceramics of an embodiment, comprises the steps:

[0023] Step S110: mixing the raw materials to obtain a mixture.

[0024] Among them, in terms of mass percentage, the raw materials include the following components: 50% to 70% of mullite, 5% to 20% of sintering aid and 20% to 40% of pore-forming agent, and the sintering aid is the melting point For the glass powder at or below 500°C, the pore-forming agent is fibrous, and the length of the pore-forming agent is 100 microns to 200 microns, and the diameter is 40 microns to 60 microns.

[0025] Specifically, the pore forming agent is selected from at least one of plant fibers and carbon fibers. Wherein, the plant fiber is selected from at least one of leaf fiber, wood fiber and bamboo fiber.

[0026] Further, the particle size of the mullite is 20 microns to 80 microns. The mullite with this particle size is beneficial to make the microporous ceramics h...

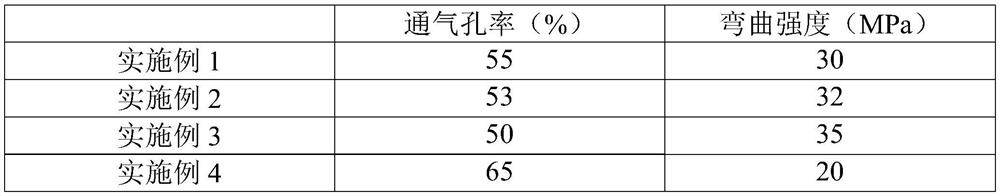

Embodiment 1

[0054] The preparation process of the ceramic heating element of the present embodiment is as follows:

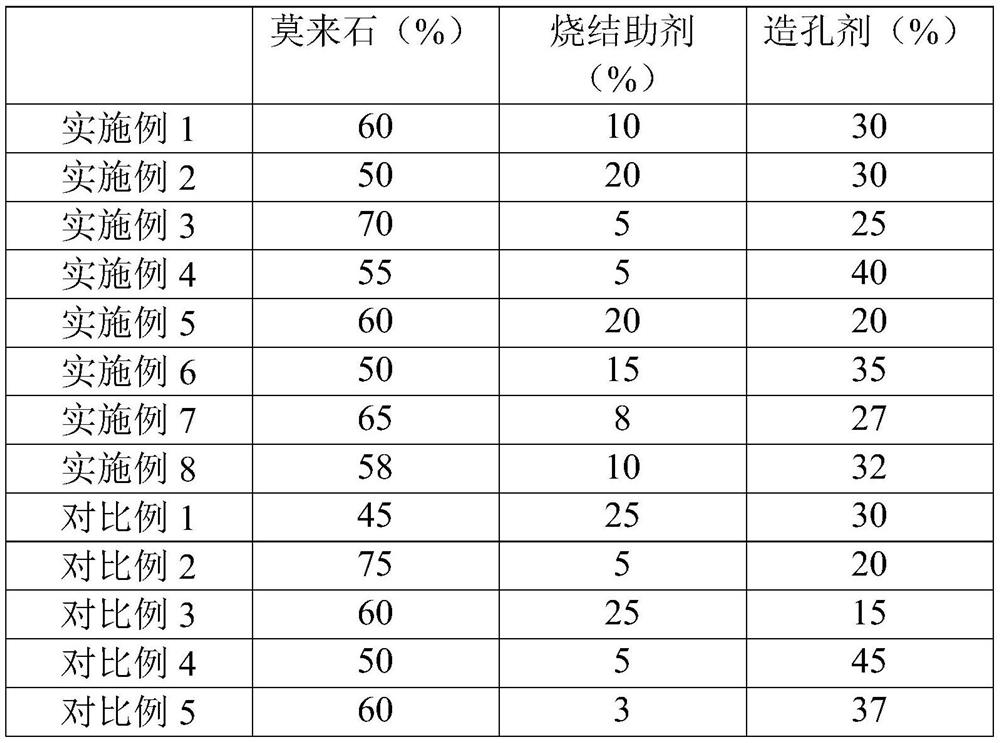

[0055] (1) Weigh each component according to the mass percentage in Table 1. Among them, the pore forming agent is leaf fiber, the length of the pore forming agent is 100 microns to 200 microns, and the diameter is 40 microns to 60 microns; the median particle size of mullite is 50 microns; the sintering aid is low melting point glass powder D240 . The median particle size of the sintering aid was 10 microns.

[0056] (2) Add the binder and deionized water to a magnetic stirrer and stir and mix at a speed of 80 rpm for 2.5 hours to obtain a premix, wherein the mass ratio of the binder, water and raw materials is 0.5:0.9:1 , the binder is polyvinyl acetate; the mullite, sintering aid and premix are stirred and mixed at a speed of 80 rpm for 18 hours, and then the pore-forming agent is added to continue to stir and mix at a speed of 40 rpm for 8 hours , to obtain the slurr...

Embodiment 2

[0064] The preparation process of the ceramic heating element of the present embodiment is as follows:

[0065] (1) Weigh each component according to the mass percentage in Table 1. The pore-forming agent is wood fiber, the length of the pore-forming agent is 100 microns to 200 microns, and the diameter is 40 microns to 60 microns; the particle size of mullite is 80 microns; the sintering aid is low-melting glass powder D245; the sintering aid The particle size is 5 microns.

[0066] (2) Add the binder and deionized water into a magnetic stirrer and stir and mix for 3 hours at a speed of 50 rpm to obtain a premixed solution, wherein the mass ratio of the binder, water and raw materials is 0.1:0.8:1 , the binder is dextrin; the mullite, the sintering aid and the premixed solution were stirred and mixed at a speed of 50 rpm for 20 hours, and then the pore-forming agent was added to continue to stir and mix for 10 hours at a speed of 25 rpm to obtain Slurry, wherein the ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com