A kind of synthetic method and device of β-aminopropionitrile

A technique for the synthesis of aminopropionitrile, which is applied in separation methods, chemical instruments and methods, and preparation of carboxylic acid nitriles, and can solve the problems of high processing costs and low yields of hazardous chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

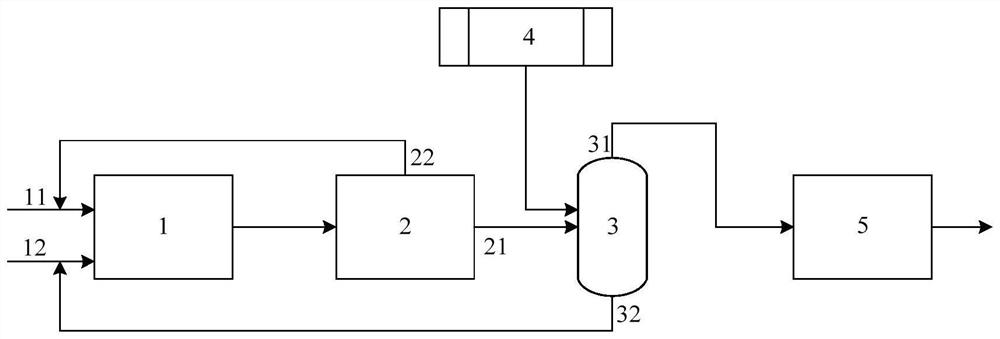

Image

Examples

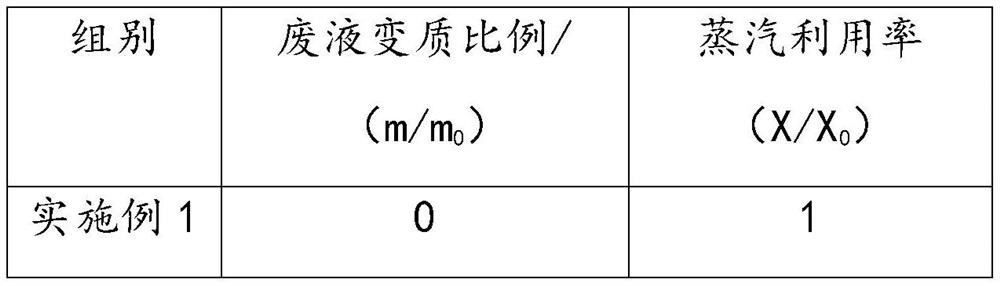

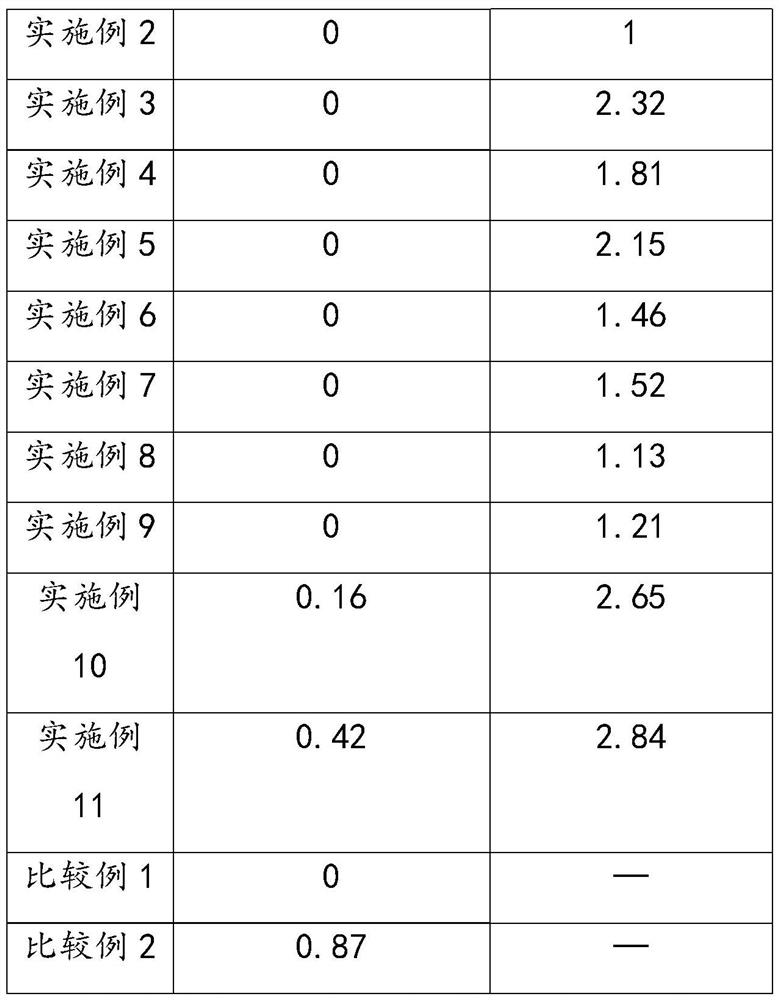

Embodiment 1

[0069] The synthetic method of the β-aminopropionitrile of present embodiment, comprises the steps:

[0070] (1) Add 50 g of β-aminopropionitrile distillation waste liquid (wherein β, β-iminodipropionitrile content is 90%) in the autoclave, add 320 g of 35% ammonia water, heat up to 150 ° C under airtight conditions, and keep the temperature at 3 MPa React for 5h, after the heat preservation finishes, drop to room temperature;

[0071] (2) Distill the mixed liquid obtained after taking out the reaction, recover ammonia water, and recover ammonia water by distillation under reduced pressure at 45-55°C and -0.095MPa. After the recovery of ammonia water is completed, when the temperature in the remaining mixed liquid reaches 100°C, start mixing Water vapor is passed into the liquid for steam distillation. The pressure of water vapor is divided into four stages and the temperature of the mixed liquid is controlled at 110-115°C. Distillation under reduced pressure at -0.095MPa. The...

Embodiment 2

[0073] The synthetic method of the β-aminopropionitrile of present embodiment, comprises the steps:

[0074] (1) Add 50 g of β-aminopropionitrile distillation waste liquid in the autoclave (the content of β, β-iminodipropionitrile is 90%), add 320 g of 35% ammonia water, heat up to 150° C. under airtight conditions, and keep the temperature for 5 hours , after the heat preservation is over, drop to room temperature;

[0075] (2) Take out the mixed solution obtained after the reaction and distill, reclaim ammonia water, after the recovery of ammonia water, when the temperature in the heated remaining mixed solution reaches 100°C, start to feed water vapor into the remaining mixed solution for steam distillation, the pressure of water vapor is divided into Four stages and control the temperature of the mixed liquid at 110-115°C, -0.095MPa vacuum distillation, the flow rate of the steam is 9-11m / s, the initial pressure is 0.06MPa, after distillation collects 27gβ-aminopropionitri...

Embodiment 3

[0079] The synthetic method of the β-aminopropionitrile of present embodiment, comprises the steps:

[0080] (1) Add 50 g of β-aminopropionitrile distillation waste liquid (wherein the content of β, β-iminodipropionitrile is 90%) in the autoclave, add 320 g of 35% ammonia water, heat up to 150 ° C under airtight conditions, and keep the temperature for 5 hours , after the heat preservation is over, drop to room temperature;

[0081] (2) Distill the mixed solution obtained after taking out the reaction, reclaim ammonia water, after the recovery of ammonia water, when the temperature in the heated remaining mixed solution reaches 100°C, start to feed water vapor into the remaining mixed solution for steam distillation, the pressure of water vapor is 0.17 MPa, and the temperature of control mixed solution is 110-115 ℃,-0.095MPa decompression distillation, the flow velocity of steam is 9-11m / s; Distillation collects and obtains β-aminopropionitrile 54.6g, through a reaction, disti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com