Catalyst, preparation method, catalyst system with polymer porous microspheres as carrier and use method

A technology of porous microspheres and catalysts, applied in the field of polypropylene Ziegler-Natta catalysts, can solve problems such as single catalytic system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a preparation method of the catalyst, which uses the metal organohalogen compound as a bridge to connect the organometallic compound of magnesium halide to the cyano-functionalized carrier, and then to the active center, that is, "-CN-Mg -Active Center-"The "double carrier" structure of the bonding mode, its preparation steps and conditions are as follows:

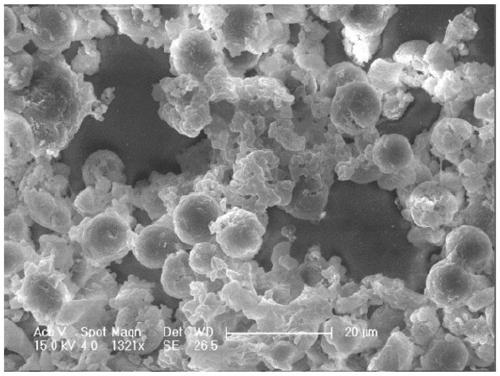

[0043] Step 1: preparing carrier cyano-functionalized monodisperse porous styrene-divinylbenzene copolymer microspheres;

[0044] Step 2: reacting the carrier in step 1 with a metal organohalogen compound to obtain a suspension;

[0045] Step 3: React the suspension obtained in Step 2 with an internal electron donor, and then add a transition metal titanium halide to react to obtain a catalyst.

[0046] According to the present invention, the cyano-functionalized monodisperse porous styrene-divinylbenzene copolymer microspheres are first prepared by "two-step seed swelling method...

Embodiment 1

[0069] Embodiment 1: the preparation of polystyrene (PS) seed microsphere

[0070] Add 10g of refined styrene, 22g of ethanol, 66g of ethylene glycol monomethyl ether, 0.1g of refined azobisisobutyronitrile and 2g of PVP-K30 into a 250mL all-necked Erlenmeyer flask, and seal it under argon protection; at 70°C , 80rpm, shake in a constant temperature water bath for 24h. After the reaction, the reaction solution was settled by centrifugation, the supernatant was removed, the precipitate was washed several times with ethanol and deionized water, and dried in vacuum to obtain PS seed microspheres with an average particle size of 4.81 μm and a viscosity-average molecular weight of 33,000. Make PS-1#.

Embodiment 2

[0071] Embodiment 2: the preparation of polystyrene (PS) seed microsphere

[0072] Add 10g of refined styrene, 44g of ethanol, 44g of ethylene glycol monomethyl ether, 0.1g of refined azobisisobutyronitrile and 2g of PVP-K30 into a 250mL all-necked Erlenmeyer flask, and seal it under argon protection; at 70°C , 80rpm, shake in a constant temperature water bath for 24h. After the reaction, the reaction solution was settled by centrifugation, the supernatant was removed, the precipitate was washed several times with ethanol and deionized water, and dried in vacuum to obtain PS seed microspheres with an average particle size of 1.93 μm and a viscosity-average molecular weight of 78,000. Make PS-2#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com