Preparation process of wireless temperature sensor utilizing electromagnetic self-energizing

A wireless temperature and preparation technology technology, applied in the direction of sensor power supply, thermometer application, thermometer components, etc., can solve the problems of increasing the difficulty of field wiring, poor anti-interference, temperature rise, etc., to achieve electrical isolation, safe, reliable, anti- The effect of strong interference ability and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the drawings:

[0035] Such as Figure 1-5 Shown:

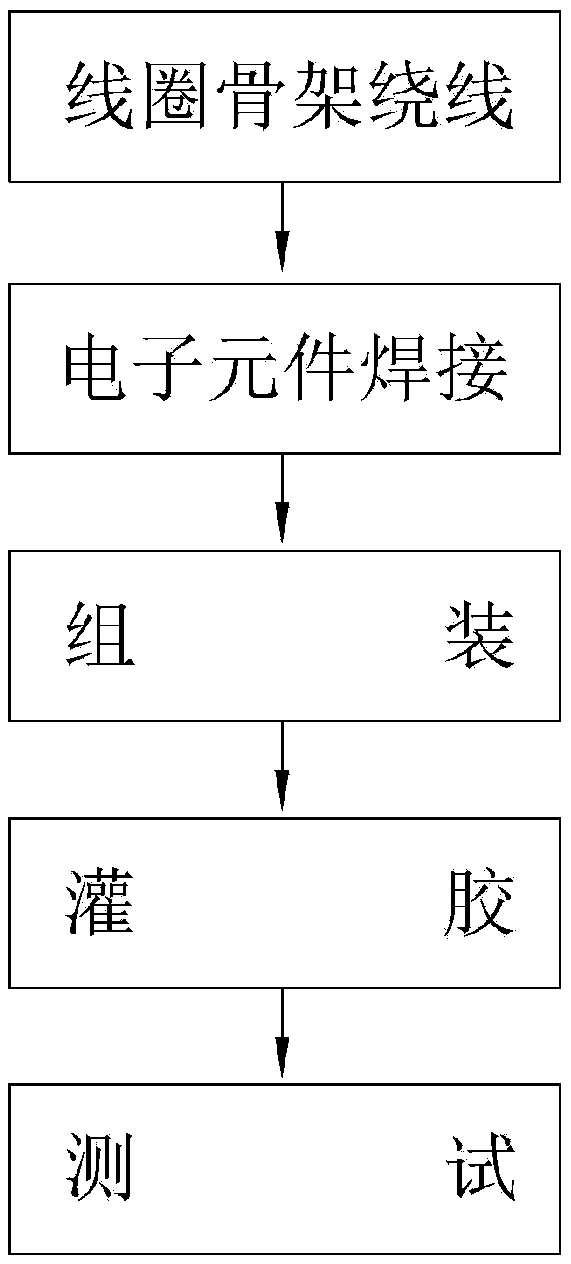

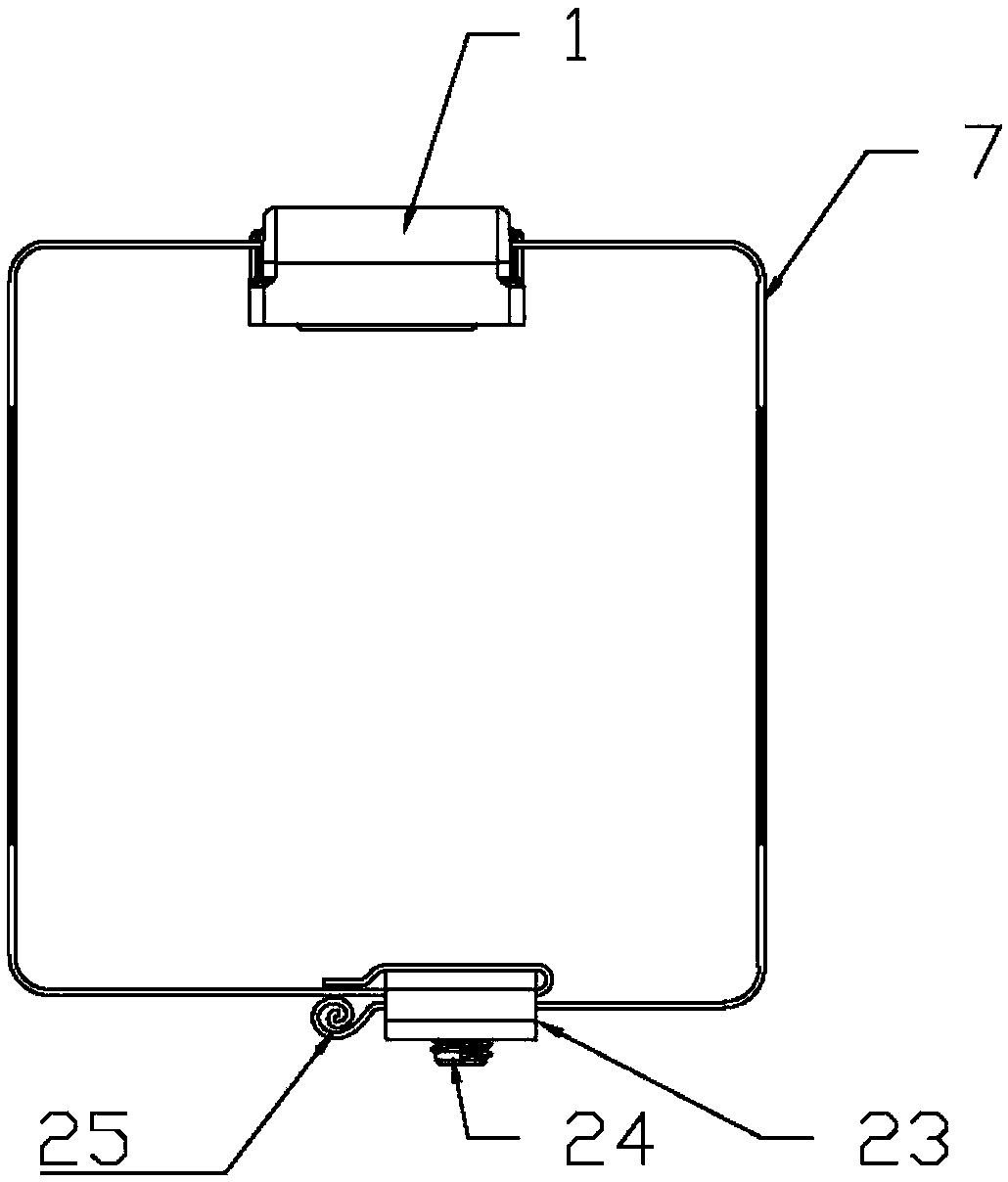

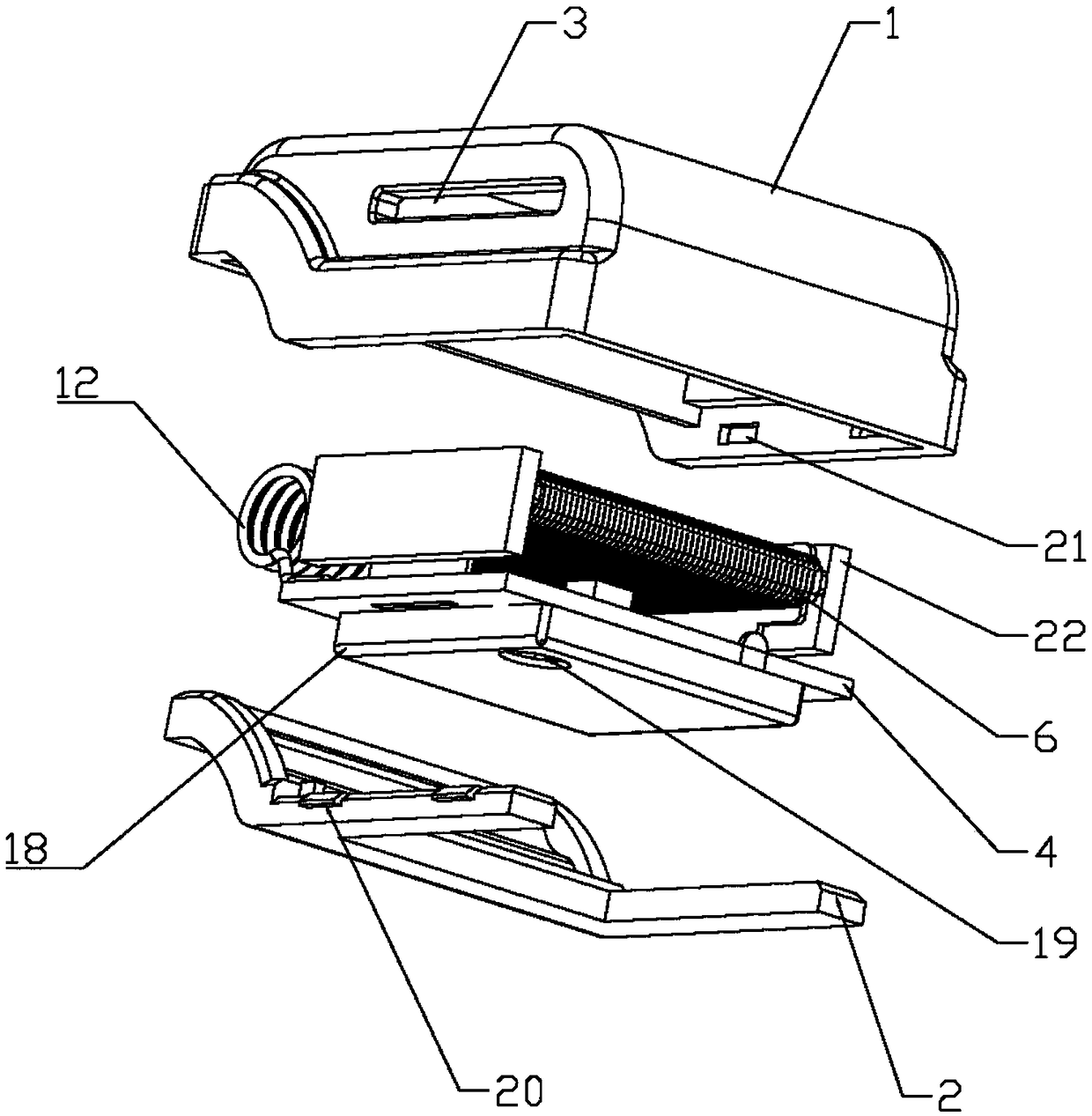

[0036] A preparation process of a wireless temperature sensor using electromagnetic self-extraction to prepare a wireless temperature sensor. The wireless temperature sensor includes a wireless temperature sensor body, an alloy belt 7 and an alloy belt fixing structure. The wireless temperature sensor body includes an upper cover 1 and a lower cover 2. , The shielding plate 18 and the PCB board 13, the two side walls of the upper cover 1 are provided with communicating through slots 3, the inner wall of the upper cover 1 is provided with an upper cover card slot 21, and the circumferential direction of the lower cover 2 is provided with an upper cover card Slot 21 is matched with pin 20. Electronic components are welded on PCB board 13. The electronic components include energy harvesting unit, rectifier diode 8, zener diode 9, main control IC chip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com