Graphene isolation baffle film and preparation method thereof

A technology of graphene and graphene layer, which is applied in semiconductor/solid-state device manufacturing, gaseous chemical plating, coating, etc. The service life of solar cells and organic light-emitting devices, the reduction of the mechanical properties of the substrate, etc., can achieve the effect of improving the performance of insulating gas and moisture, improving the physical and chemical properties, and increasing the space saturation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

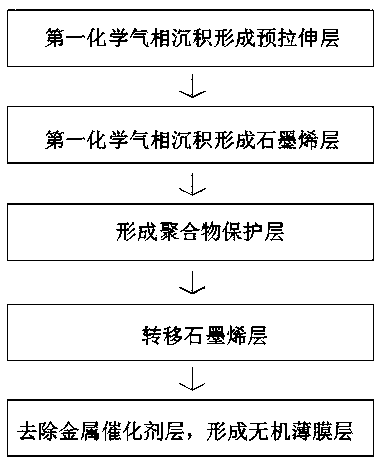

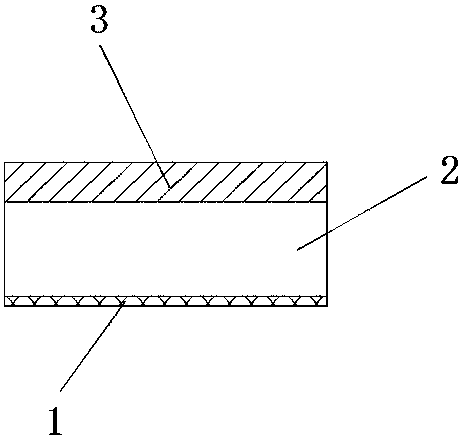

[0033] according to figure 1 , 2 Shown, the present invention proposes a kind of technical scheme:

[0034] A kind of graphene isolating film, comprises target substrate 1, inorganic thin film layer 2 and graphene layer 3, and described target substrate 1 is provided with inorganic thin film layer 2, and described inorganic thin film layer 2 is made up of inorganic material, and described target The substrate 1 is a flexible substrate, the thickness of the target substrate 1 is 10 microns, and a graphene layer 3 is arranged above the inorganic thin film layer 2 .

[0035] A further improvement is: the target substrate 1 is specifically a polyimide substrate, a polyethersulfone substrate, a polyether ether ketone substrate, a polyethylene terephthalate substrate, a polyvinyl chloride substrate or a polycarbonate substrate. A sort of.

[0036] A preparation method for a graphene insulating barrier film, comprising the following steps:

[0037] Step 1: The first chemical vapo...

Embodiment 2

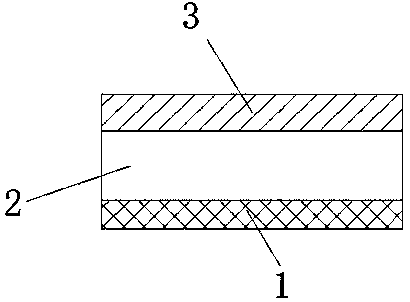

[0048] according to figure 1 , 3 Shown, the present invention proposes a kind of technical scheme:

[0049] A kind of graphene isolating film, comprises target substrate 1, inorganic thin film layer 2 and graphene layer 3, and described target substrate 1 is provided with inorganic thin film layer 2, and described inorganic thin film layer 2 is made up of inorganic material, and described target The substrate 1 is a flexible substrate, the thickness of the target substrate 1 is 500 microns, and a graphene layer 3 is arranged above the inorganic thin film layer 2 .

[0050] A further improvement is: the target substrate 1 is specifically a polyimide substrate, a polyethersulfone substrate, a polyether ether ketone substrate, a polyethylene terephthalate substrate, a polyvinyl chloride substrate or a polycarbonate substrate. A sort of.

[0051] A preparation method for a graphene insulating barrier film, comprising the following steps:

[0052] Step 1: The first chemical vap...

Embodiment 3

[0063] according to figure 1 , 4 Shown, the present invention proposes a kind of technical scheme:

[0064] A kind of graphene isolating film, comprises target substrate 1, inorganic thin film layer 2 and graphene layer 3, and described target substrate 1 is provided with inorganic thin film layer 2, and described inorganic thin film layer 2 is made up of inorganic material, and described target The substrate 1 is a flexible substrate, the thickness of the target substrate 1 is 1000 microns, and a graphene layer 3 is arranged above the inorganic thin film layer 2 .

[0065] A further improvement is: the target substrate 1 is specifically a polyimide substrate, a polyethersulfone substrate, a polyether ether ketone substrate, a polyethylene terephthalate substrate, a polyvinyl chloride substrate or a polycarbonate substrate. A sort of.

[0066] A preparation method for a graphene insulating barrier film, comprising the following steps:

[0067] Step 1: The first chemical va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com