Preparation method of graphene integrated heating decorative plate

A technology of graphene and decorative plates, applied in the field of graphene, can solve problems such as low heat conversion efficiency and saturation, and achieve the effects of improving physical and chemical properties, reducing preparation costs, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

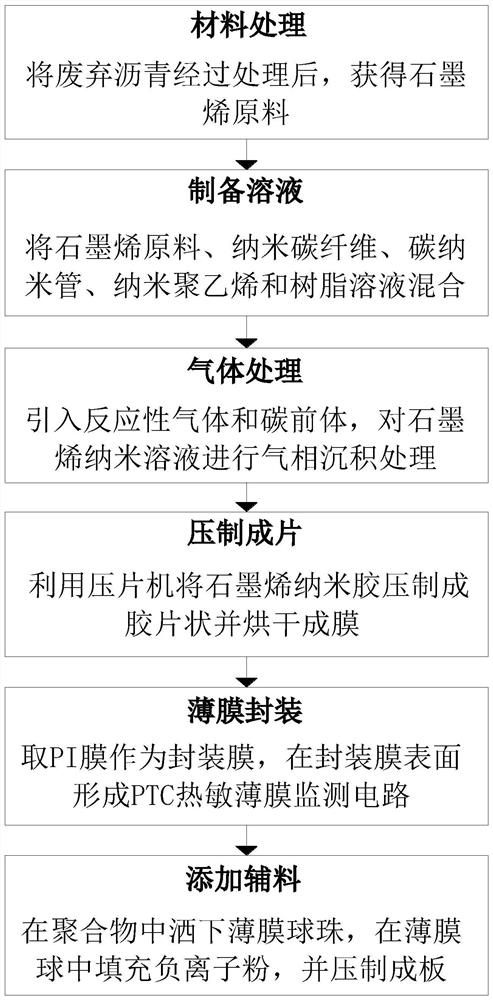

[0029] according to figure 1 , 2 As shown, this embodiment proposes a method for preparing a graphene-integrated heating decorative board, including the following steps:

[0030] Material treatment, the waste asphalt is sieved and centrifuged, then mixed with additives, and then carbonized at high temperature to obtain graphene raw materials;

[0031] Prepare a solution, mix and stir the graphene raw material, nano-carbon fiber, nano-polyethylene and resin solution at room temperature, and control the stirring reaction speed to 300-500 rpm, and stir for 1-3 hours to prepare a graphene nano-solution;

[0032] Gas treatment, introducing reactive gases and carbon precursors, performing gas phase deposition on the graphene nano solution, and cooling the graphene nano solution to room temperature after treatment;

[0033] Press into sheets, turn on the vacuum refrigerator, first pre-freeze the graphene nano solution, keep it for 1-1.5 hours, and the pre-freezing ends; move the pr...

Embodiment 2

[0038] This embodiment proposes a method for preparing a graphene-integrated heating decorative board, including the following steps:

[0039]In the material processing, the waste asphalt is crushed and screened, and then mixed with a solvent to obtain a mixture, the mixture is centrifugally filtered to remove particulate matter, and the supernatant slurry is obtained, and then separated to obtain asphalt, and the asphalt is mixed with additives Stirring reaction is carried out to obtain the base material, the base material is carbonized at high temperature and ground to obtain carbon powder, the carbon powder is baked at high temperature, and mixed with acetone solution to obtain a carbon powder mixture, and the carbon powder mixture is introduced into ultrasonic vibration Shake and disperse in a container, and then atomize and dry to obtain graphene. The solvent is a mixture of one or more of C2-C5 dichlorinated hydrocarbons, C6-C9 alkanes or C9-C10 single-ring aromatic hydr...

Embodiment 3

[0043] This embodiment proposes a method for preparing a graphene-integrated heating decorative board, including the following steps:

[0044] In the gas treatment, the graphene nano solution is put into the reaction furnace, and then the mixed gas containing reactive gas and carbon precursor is introduced into the graphene nano solution at a speed of 80-120 ml / min in the standard state, and then the reaction The temperature in the furnace is raised to 100-15 degrees Celsius, and the graphene nano solution is heat-treated for 10-30 seconds in a pressure environment of 100-760 mTorr, and then the mixed gas containing reactive gas and carbon precursor is introduced again, and the reaction is controlled The pressure in the furnace is 100-760 millitorr, and the reaction is carried out for 1-3 minutes, and then the reactive gas is introduced into the reaction furnace at a rate of 160 ml / min in the standard state, and the pressure in the reactor is adjusted to be 100-760 millitorr, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com