Graphene-based photothermal conversion material and preparation and application methods thereof

A light-to-heat conversion material and light-to-heat conversion technology, applied in the field of light conversion, can solve the problem of high cost of concentrators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

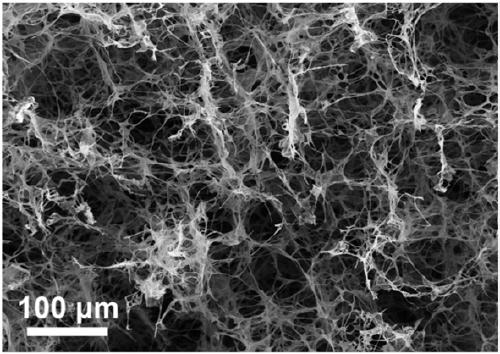

Embodiment 1

[0094] Disperse a certain amount of graphene oxide in ethanol to prepare a dispersion with a concentration of 0.5 mg / mL. Take out 70 mL of the dispersion, pour it into a 100 mL stainless steel reaction kettle with a Teflon lining, and react at 180° C. for 12 hours. Transfer the prepared graphene oxide material containing ethanol to an appropriate container, and then slowly replace the ethanol with water. Wherein the graphene oxide material is first placed in a series of mixed solutions of ethanol and water with multiple concentration gradients, wherein the ratio of ethanol and water in the series of mixed solutions is 10:1, 5: 1, 3:1, 1:1, 1:3, 1:5, 1:10; finally, the graphene oxide material is placed in pure water to replace ethanol in the graphene oxide material with water. It was then freeze-dried and then soaked in 5% H 2 The samples were calcined at 800°C for 1 h in an Ar atmosphere, and finally the samples were placed in an ozone generator for ozone treatment for 15 m...

Embodiment 2

[0098] Disperse a certain amount of graphene oxide in ethanol to prepare a dispersion with a concentration of 0.5 mg / mL. Take out 70 mL of the dispersion, pour it into a 100 mL stainless steel reaction kettle with a Teflon lining, and react at 180° C. for 12 hours. Transfer the prepared graphene oxide material containing ethanol to an appropriate container, and then slowly replace the ethanol with water. Wherein the graphene oxide material is first placed in a series of mixed solutions of ethanol and water with multiple concentration gradients, wherein the ratio of ethanol and water in the series of mixed solutions is 10:1, 5: 1, 3:1, 1:1, 1:3, 1:5, 1:10; finally, the graphene oxide material is placed in pure water to replace ethanol in the graphene oxide material with water. It was then freeze-dried and then soaked in 5% H 2 The samples were calcined at 800°C for 1 h in an Ar atmosphere, and finally the samples were placed in an ozone generator for ozone treatment for 15 m...

Embodiment 3

[0102] Disperse a certain amount of graphene oxide in N,N-dimethylformamide to prepare a dispersion with a concentration of 1.0 mg / mL. Take out 70mL of the dispersion, pour it into a 100mL stainless steel reaction kettle with polytetrafluoroethylene lining, and react at 180°C for 24 hours. Transfer the prepared graphene oxide material filled with N,N-dimethylformamide to an appropriate container, and then slowly replace N,N-dimethylformamide with water. It was then freeze-dried and then soaked in 5% H 2 The samples were calcined at 1000°C for 0.5 h in an Ar atmosphere, and finally the samples were placed in an ozone generator for ozone treatment for 20 min. A graphene-based light-to-heat conversion material is obtained.

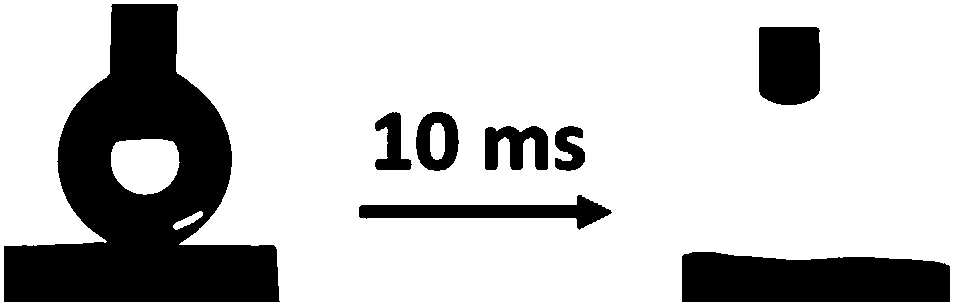

[0103]The material can be used to make light-to-heat conversion devices (such as seawater desalination and sewage treatment devices, etc.), a design prototype of this device is as Figure 6 shown. In order to make the sample can be used directly on the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com