Polycarboxylic acid water reducer and preparation method thereof

A technology of water reducing agent and polycarboxylic acid, which is applied in the field of polycarboxylic acid water reducing agent and its preparation, to achieve the effects of low slump, high water reducing property and simple reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

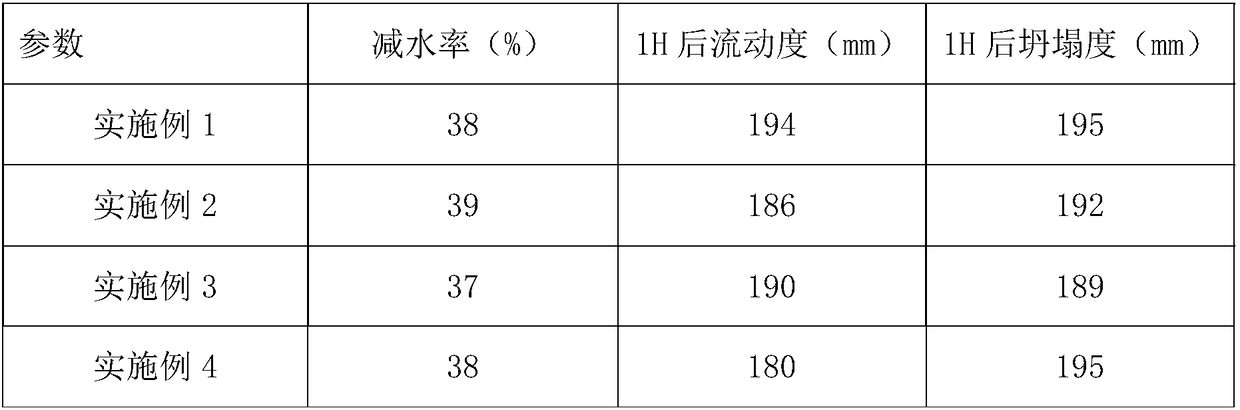

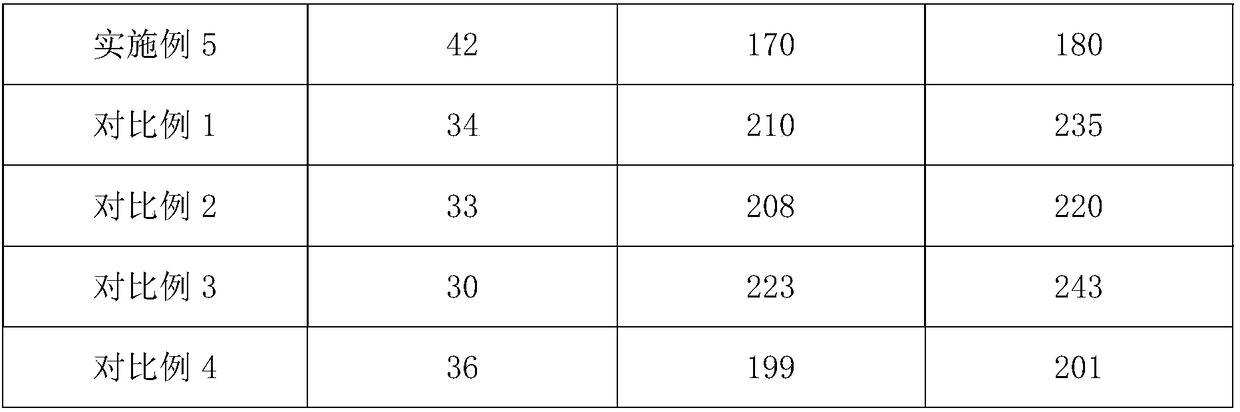

Examples

Embodiment 1

[0017] A polycarboxylate water reducer, comprising the following raw materials: polyoxyethylene allyl ester macromonomer 100kg, sodium methacrylate sulfonate 1kg, acrylic acid 50kg, potassium hydroxide 5kg, tap water 70kg, chlorinated Diphenylphosphine 2kg, copper chloride 0.5kg.

[0018] A method for preparing a polycarboxylate water reducer, comprising the following steps: Step 1: Add water to a reaction tank, heat it to 50 degrees Celsius, start stirring at a stirring speed of 3000r / min, and evenly add polyoxyethylene allyl ester Macromonomer, stir for 1 hour, adjust the speed to 1000r / min; Step 2: stop heating, add acrylic acid, copper chloride and chlorinated diphenylphosphine to the reaction kettle at the same time, continue to stir for 1 hour, adjust the speed to 1000r / min Step 3: Add sodium methpropylene sulfonate to the reaction tank, and keep the stirring speed at 500; Step 4: Add potassium hydroxide to the reaction tank, and adjust the pH to 7.

Embodiment 2

[0020] A polycarboxylate water reducer, comprising the following raw materials: 120kg of polyoxyethylene allyl ester macromonomer, 5kg of sodium methacrylate sulfonate, 80kg of acrylic acid, 10kg of potassium hydroxide, 90kg of tap water, chlorinated diphenyl Phosphine 5kg, copper chloride 1kg.

[0021] A method for preparing a polycarboxylate water reducer, comprising the following steps: Step 1: Add water to a reaction tank, heat it to 80 degrees Celsius, start stirring at a stirring speed of 4000r / min, and evenly add polyoxyethylene allyl ester Macromonomer, stir for 3 hours, adjust the rotation speed to 2000r / min; Step 2: stop heating, add acrylic acid, copper chloride and chlorinated diphenylphosphine to the reaction kettle at the same time, continue to stir for 1.5 hours, adjust the rotation speed to 1000r / min Step 3: Add sodium methpropylene sulfonate to the reaction tank and keep the stirring speed at 1000r / min; Step 4: Add potassium hydroxide to the reaction tank to a...

Embodiment 3

[0023] A polycarboxylate water reducer, comprising the following raw materials: polyoxyethylene allyl ester macromonomer 105kg, sodium methacrylate sulfonate 2kg, acrylic acid 60kg, potassium hydroxide 6kg, tap water 75kg, chlorinated diphenyl Phosphine 3kg, copper chloride 0.6kg.

[0024] A method for preparing a polycarboxylate water reducer, comprising the following steps: Step 1: Add water to a reaction tank, heat it to 50 degrees Celsius, start stirring at a stirring speed of 3000r / min, and evenly add polyoxyethylene allyl ester Macromonomer, stir for 1 hour, adjust the speed to 1000r / min; Step 2: stop heating, add acrylic acid, copper chloride and chlorinated diphenylphosphine to the reaction kettle at the same time, continue to stir for 1 hour, adjust the speed to 1000r / min Step 3: Add sodium methpropylene sulfonate to the reaction tank, and keep the stirring speed at 500; Step 4: Add potassium hydroxide to the reaction tank, and adjust the pH to 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com