Compound, display panel and display device

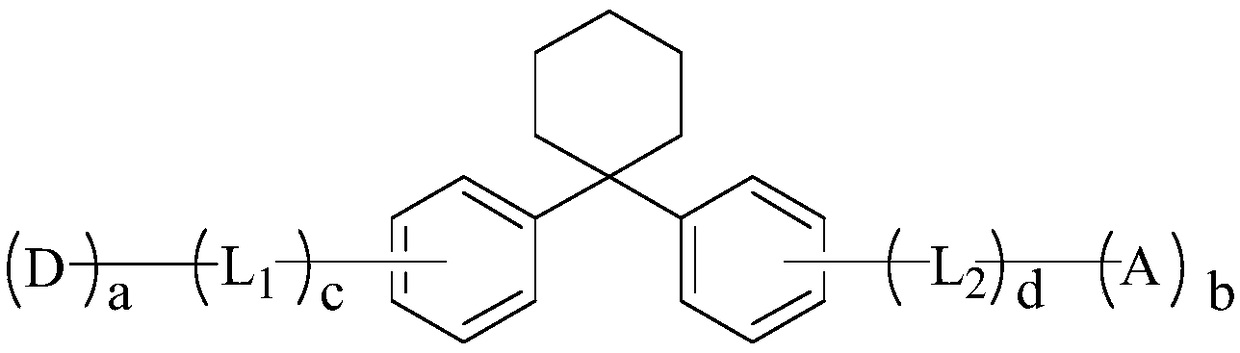

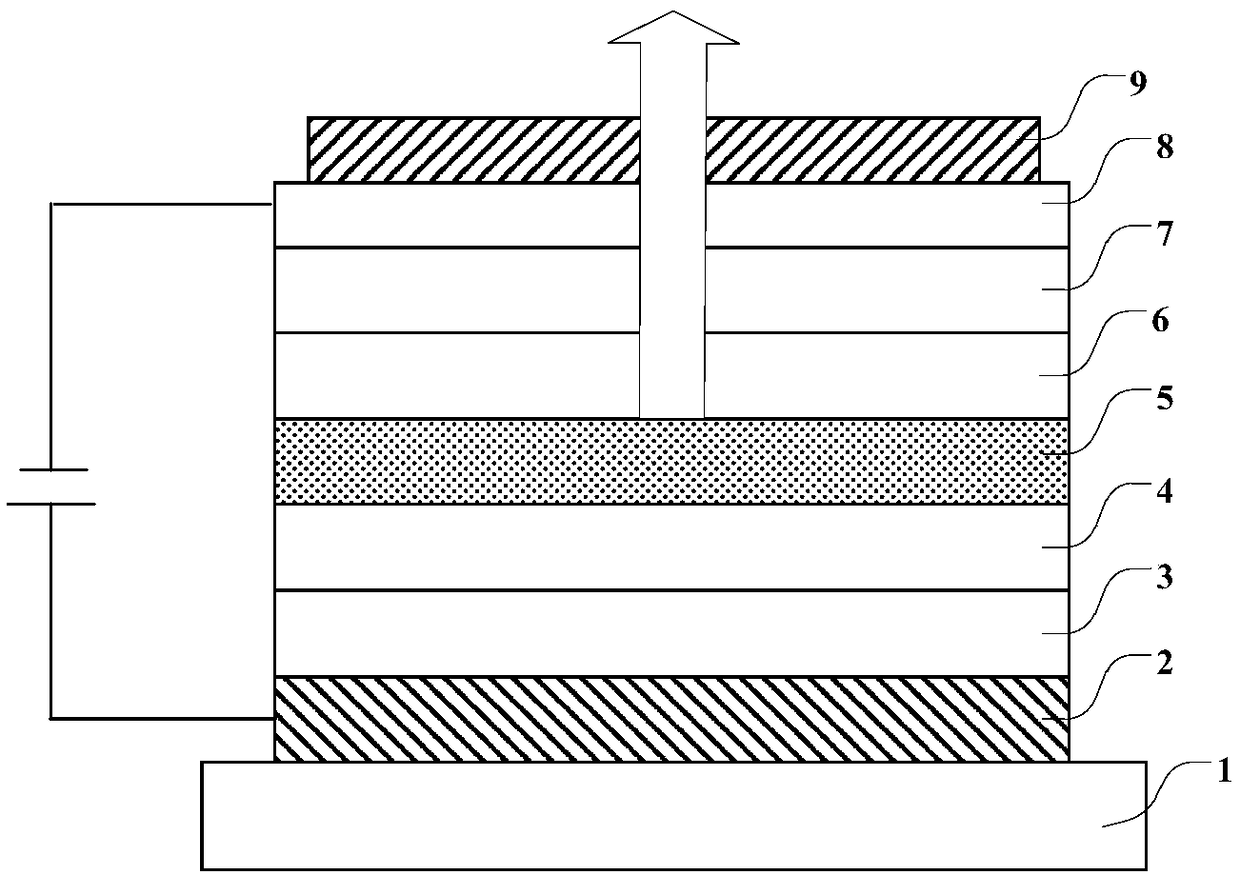

A compound and connection position technology, which is applied in the field of organic electroluminescent materials, can solve problems such as the difficulty in developing doped materials, and achieve the goals of improving equilibrium migration, improving light extraction efficiency, high glass transition temperature and molecular thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Synthesis of Compound H004

[0083]

[0084] In a 250mL round-bottomed flask, mix 1,1-bis(4-iodophenyl)cyclohexane (15mmol), copper iodide (15mmol), potassium tert-butoxide (65mmol), 1,2-diaminocyclohexane Alkane (12mmol) and diarylamine (25mmol) were added to dry 1,4-dioxane (400mL), refluxed under nitrogen atmosphere for 48 hours, the resulting intermediate was cooled to room temperature, added to water, and passed through silicon After filtration through a pad of celite, the filtrate was extracted with dichloromethane, washed with water, and dried over anhydrous magnesium sulfate. After filtration and evaporation, the crude product was purified by silica gel column chromatography to obtain intermediate product H004-1.

[0085] In a 250 mL round bottom flask, intermediate H004-1 (15 mmol) and potassium acetate (40 mmol) were mixed with dry 1,4-dioxane (60 mL), Pd(PPh 3 ) 2 Cl 2 (0.4mmol) and pinacol diboronate (25mmol) were mixed, and stirred at 90° C. under a n...

Embodiment 2

[0089] Synthesis of compound H022

[0090]

[0091] In a 250mL round-bottomed flask, mix 1,1-bis(4-iodophenyl)cyclohexane (15mmol), copper iodide (15mmol), potassium tert-butoxide (65mmol), 1,2-diaminocyclohexane Alkane (12mmol) and 9-carbazole (25mmol) were added to dry 1,4-dioxane (400mL), refluxed under nitrogen atmosphere for 48 hours, the obtained intermediate was cooled to room temperature, added to water, and passed through It was filtered through a celite pad, and the filtrate was extracted with dichloromethane, washed with water, and dried over anhydrous magnesium sulfate. After filtration and evaporation, the crude product was purified by silica gel column chromatography to obtain the intermediate product H013-1.

[0092] In a 250 mL round bottom flask, intermediate H013-1 (15 mmol) and potassium acetate (40 mmol) were mixed with dry 1,4-dioxane (60 mL), Pd(PPh 3 ) 2 Cl 2 (0.4mmol) and pinacol diboronate (25mmol) were mixed, and stirred at 90° C. under a nitrog...

Embodiment 3

[0096] Synthesis of Compound H048

[0097]

[0098] In a 250mL round-bottomed flask, mix 1,1-bis(4-iodophenyl)cyclohexane (15mmol), copper iodide (15mmol), potassium tert-butoxide (65mmol), 1,2-diaminocyclohexane Alkane (12mmol) and 9,9-dimethylacridine (25mmol) were added to dry 1,4-dioxane (400mL), refluxed under nitrogen atmosphere for 48 hours, and the obtained intermediate was cooled to room temperature, Added to water, then filtered through a pad of celite, the filtrate was extracted with dichloromethane, then washed with water, and dried over anhydrous magnesium sulfate, after filtration and evaporation, the crude product was purified by silica gel column chromatography to give intermediate product H048-1.

[0099] In a 250 mL round bottom flask, intermediate H048-1 (15 mmol) and potassium acetate (40 mmol) were mixed with dry 1,4-dioxane (60 mL), Pd(PPh 3 ) 2 Cl 2 (0.4mmol) and pinacol diboronate (25mmol) were mixed, and stirred at 90° C. under a nitrogen atmosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com