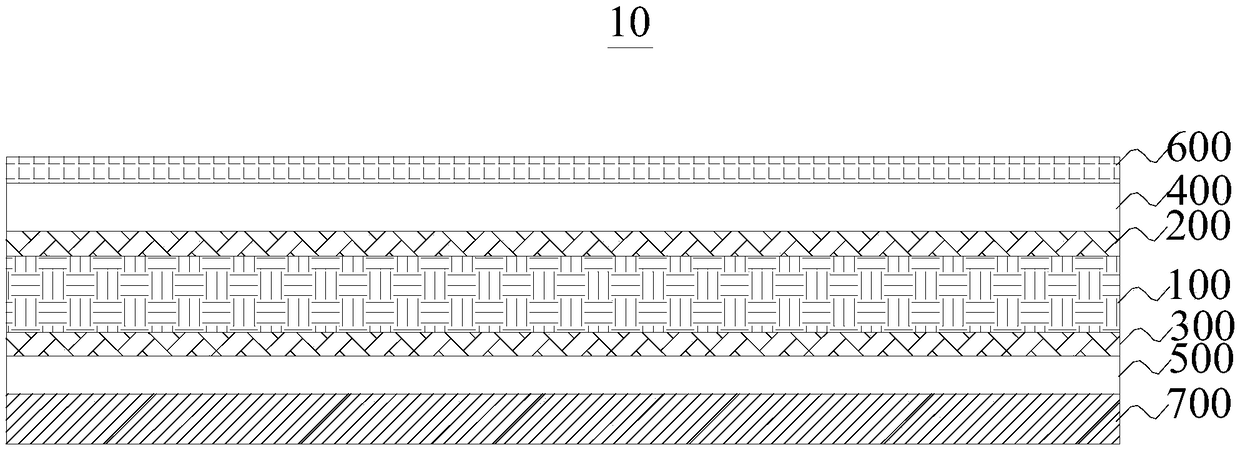

Flexible packaging film for lithium ion battery, and preparation method of flexible packaging film

A lithium-ion battery, flexible packaging film technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of lithium-ion battery failure, leakage, fire and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

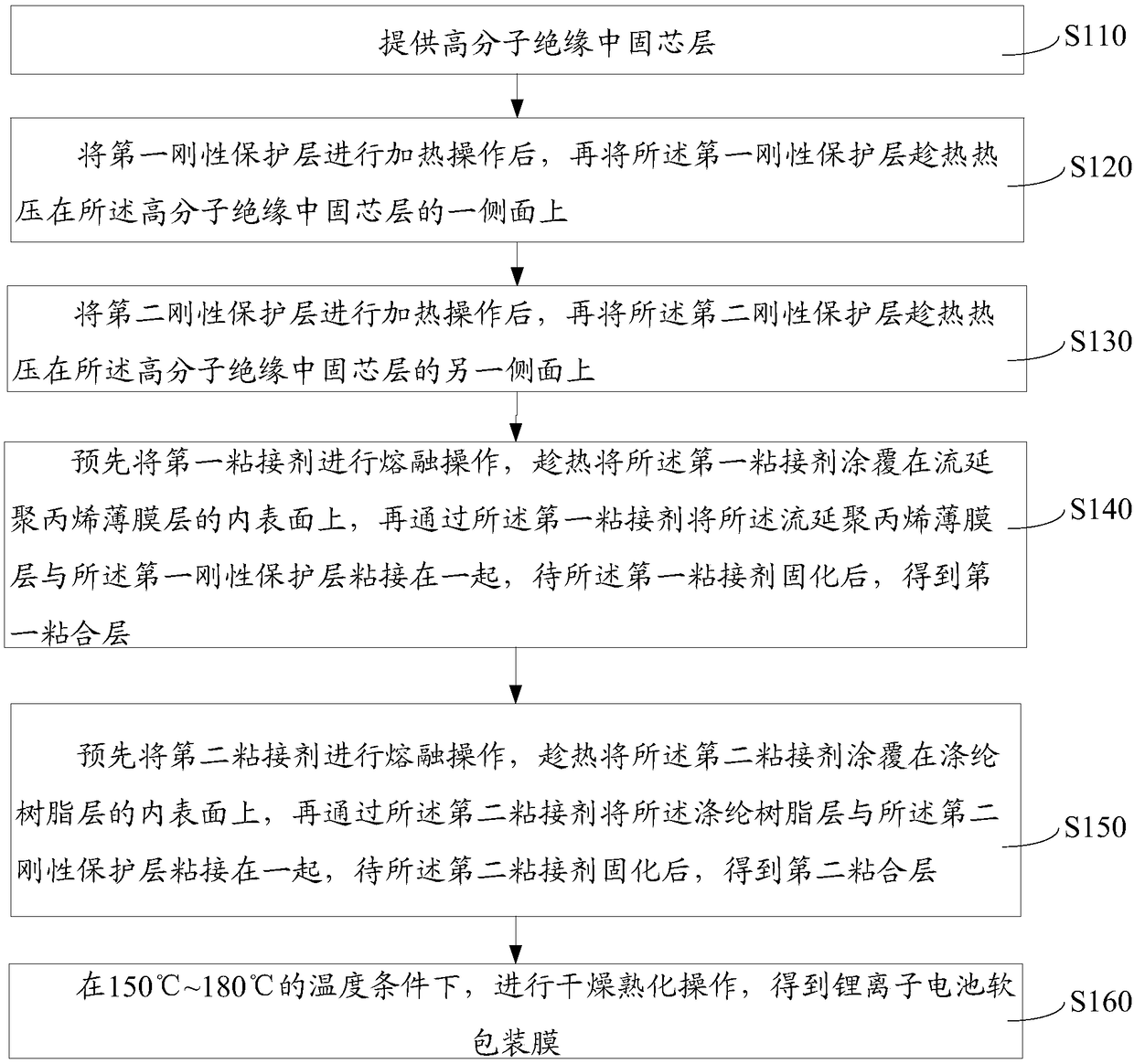

[0055] see figure 2 , a preparation method of lithium-ion battery flexible packaging film, comprising the steps of:

[0056] S110, providing a solid core layer of polymer insulation.

[0057] By providing a solid core layer in the polymer insulation, as the middle layer of the lithium-ion battery flexible packaging film 10, it plays a good supporting role, and at the same time, due to its good insulation performance, it avoids short-circuiting with the tabs like aluminum foil. Problems, good barrier properties and puncture resistance, and good resistance to electrolyte stability, which can prevent the occurrence of electrochemical corrosion in soft-pack lithium-ion batteries.

[0058] In one of the embodiments, the thickness of the solid core layer in the polymer insulation is 20um-30um. It can be understood that the thickness of the solid core layer in the polymer insulation is smaller than that of the conventional aluminum-plastic film, which reduces the difficulty of pac...

Embodiment 1

[0076] Provide a PP layer with a thickness of 20um;

[0077] After heating the PET layer with a thickness of 10um, the PET layer is hot-pressed on one side of the PP layer with a pressure of 0.5Mpa;

[0078] After heating the PMMA layer with a thickness of 10um, the PMMA layer is hot pressed on the other side of the PP layer with a pressure of 0.5Mpa;

[0079] Under the temperature condition of 160°C, the polyurethane adhesive is melted, and the polyurethane adhesive is coated on the inner surface of the cast polypropylene film layer with a thickness of 15um while it is hot, and then the flow is passed through the polyurethane adhesive. The extended polypropylene film layer and the PET layer are bonded together, and after the polyurethane adhesive is cured, the first adhesive layer is obtained;

[0080] Under the temperature condition of 170°C, the polyurethane adhesive is melted, and the polyurethane adhesive is coated on the inner surface of the polyester resin layer with a...

Embodiment 2

[0083] Provide a PP layer with a thickness of 25um;

[0084] After heating the PMMA layer with a thickness of 15um, the PMMA layer is hot-pressed on one side of the PP layer with a pressure of 0.5Mpa;

[0085] After heating the ABS layer with a thickness of 10um, press the ABS layer on the other side of the PP layer while it is hot with a pressure of 1.5Mpa;

[0086] Under the temperature condition of 180°C, the epoxy resin adhesive is melted, and the epoxy resin adhesive is coated on the inner surface of the cast polypropylene film layer with a thickness of 20um, and then passed through The polyurethane adhesive bonds the cast polypropylene film layer and the PMMA layer together, and after the polyurethane adhesive is cured, the first adhesive layer is obtained;

[0087] Under the temperature condition of 180°C, the polyurethane adhesive is melted, and the polyurethane adhesive is coated on the inner surface of the polyester resin layer with a thickness of 20um while it is h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com