Catalyst suitable for aromatization of low carbon hydrocarbons in Fischer-Tropsch synthetic oil and its preparation and application

A Fischer-Tropsch synthetic oil and catalyst technology, which is applied in the direction of carbon compound catalysts, physical/chemical process catalysts, catalysts, etc., can solve the problems of increasing the difficulty of industrial scale-up preparation, complex ion solution process, and low selectivity of aromatic hydrocarbons, etc., to achieve optimal Reaction stability, inhibition of carbon deposition rate, low yield of aromatics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

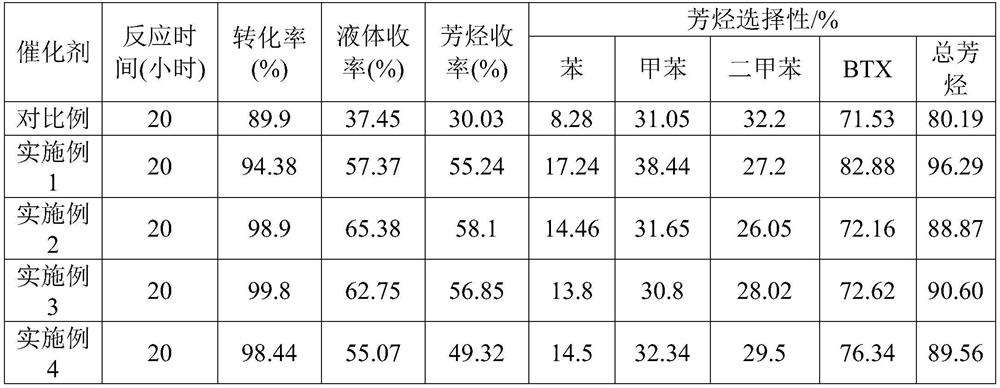

Examples

Embodiment 1

[0033] Take HZSM-5 molecular sieve with a silicon-to-alumina ratio of 25, and roast it in a muffle furnace at 500 °C for 6 hours for pretreatment; 40g of pretreated HZSM-5 molecular sieve and 10g of SB powder are fully mixed, and then use 10g of dilute nitric acid and an appropriate amount to remove Kneading with ionized water, molding on an extruder to obtain a 2-5mm bar-shaped solid, drying at 80°C for 3 hours, calcining at 550°C for 6 hours, crushing and sieving to obtain a precursor of 20-40 meshes; 500°C, airspeed 5.0 hours -1 The catalyst carrier was obtained by steam treatment for 2 hours; 15g of the catalyst carrier was impregnated into 0.1mol / LZn(NO) 3 )2, 0.1mol / L Ga(NO 3 )3 and 0.1mol / L Ni(NO 3 ) 2 The mixed aqueous solution was stirred at room temperature for 1 hour, stood for 24 hours, dried at 120 °C for 12 hours, and then calcined at 500 °C for 6 hours to obtain a catalyst with a loading content of 1%Zn-1%Ga-1%Ni / ZSM-5 .

Embodiment 2

[0035] Take HZSM-5 molecular sieve with a silicon-alumina ratio of 38, and calcinate it in a muffle furnace at 520 ° C for 4 hours for pretreatment; 20g of pretreated HZSM-5 molecular sieve and 10g of SB powder are fully mixed, and then 8.5g of dilute nitric acid and an appropriate amount are added. Deionized water, shape on an extruder to obtain a 2-5mm bar-shaped solid, dry at 100°C for 4 hours, calcinate at 520°C for 3 hours, and crush the sieved 20-40 mesh precursor; 550°C, airspeed 5.0 hours -1 The catalyst carrier was obtained by steam treatment for 2 hours; 15 g of the precursor was impregnated into 0.15 mol / L Zn(NO 3 ) 2 , 0.05mol / L Ga(NO 3 ) 3 and 0.10mol / L Ni(NO 3 ) 2 In aqueous solution, stirred at room temperature for 1 hour, stood for 18 hours, dried at 120°C for 24 hours, and then calcined at 550°C for 2 hours to obtain 1.5%Zn-0.5%Ga-1%Ni / ZSM-5 catalyst.

Embodiment 3

[0037] Take HZSM-5 molecular sieve with a silicon-to-alumina ratio of 80, and roast it in a muffle furnace at 600 °C for 2 hours for pretreatment; 50g of pretreated HZSM-5 molecular sieve is fully mixed with 40g of SB powder, and then 28g of dilute nitric acid and an appropriate amount are added. Deionized water, shape on an extruder to obtain a 2-5mm bar-shaped solid, dry at 110°C for 6 hours, calcinate at 550°C for 3 hours, and crush the sieved 20-40 mesh precursor; 600°C, airspeed 8.0 hours -1 The catalyst carrier was obtained by steam treatment for 1 hour; 15g of the precursor was impregnated into 0.35mol / LZn(NO3)2, 0.1mol / L Ga(NO3)2 3 ) 3 and 0.05mol / L Ni(NO 3 ) 2 In the aqueous solution, stirred at room temperature for 1 hour, stood for 18 hours, dried at 120°C for 24 hours, and then calcined at 480°C for 6 hours to obtain 3.5%Zn-1%Ga-0.5%Ni / ZSM-5 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com