Recovery method of waste polyester blended fabric containing natural fibers

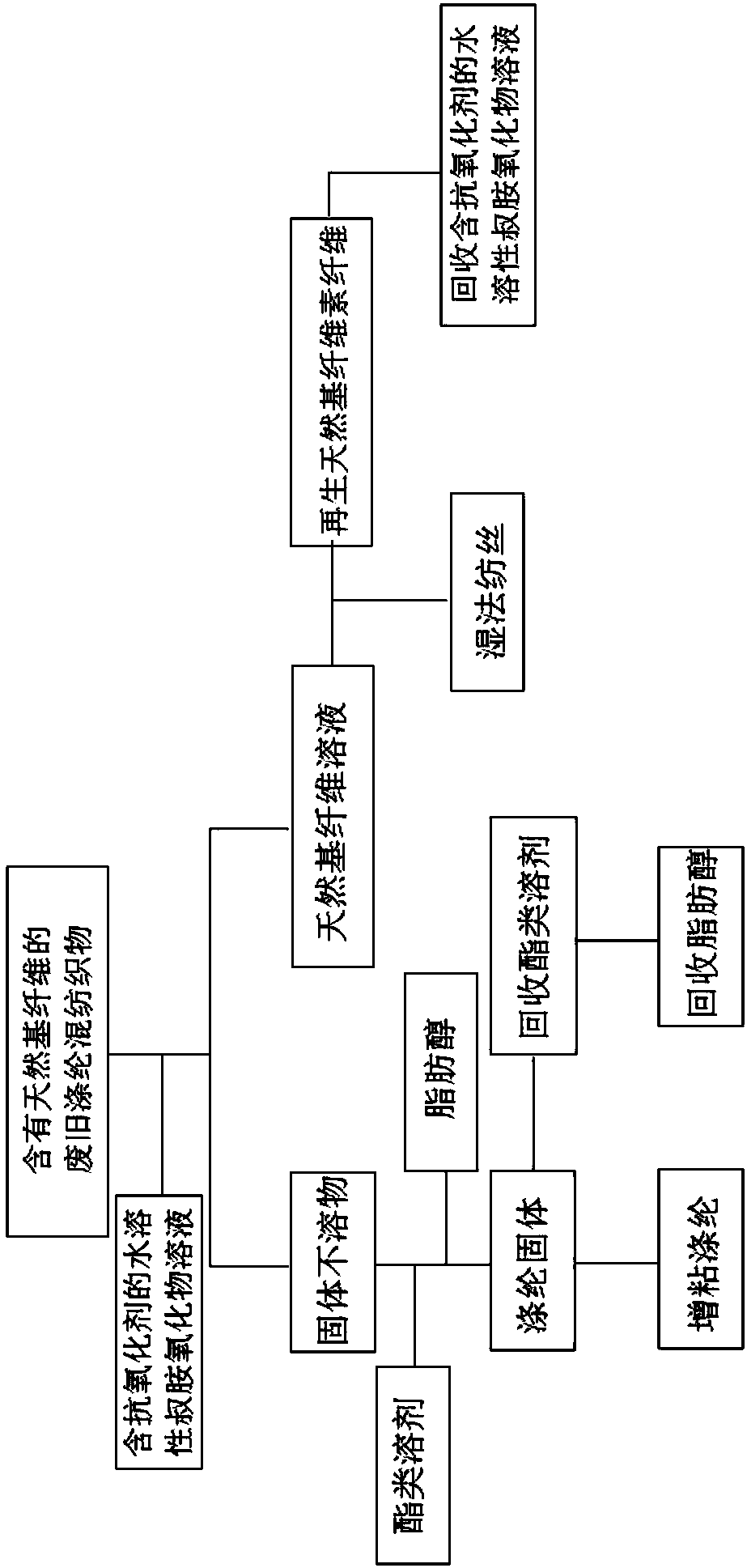

A recycling method and technology for blended fabrics, which are applied in the recycling field of waste polyester blended fabrics, can solve the problems of complete separation of difficult-to-recycle materials, affecting the purity of recycling, and harming the environment, achieving a wide range of applications, wide applicability, and reducing environmental hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

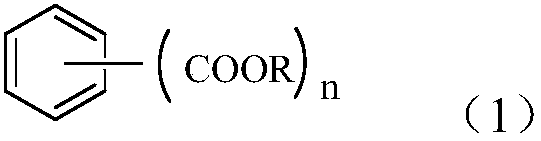

Embodiment 1

[0064] Put 10 g of waste polyester-wool blended fabrics with a water content of 5%, a polyester content of 50%, and a wool content of 10% in a 4-methylmethanol solution containing 0.5 g of propyl gallate and 12% of deionized water at 65°C. Swell in 45ml of morphine-N-oxide solution for 30min, and then raise the temperature to 100°C to fully dissolve the natural base fibers in it for 60min. The mixture is separated from solid and liquid by vacuum filtration, the obtained protein / cellulose spinning dope is continuously extruded into water from the spinneret, and mechanically stretched 3 times to obtain regenerated protein / cellulose fibers, which are recovered and ion exchanged The column was purified from a solution of 4-methylmorpholine-N-oxide containing propyl gallate. The separated solid insoluble matter was immersed in 50ml dimethyl terephthalate at 170°C for 15 minutes, and then slowly poured into methanol. When the temperature dropped to 50°C, the precipitated polyester p...

Embodiment 2

[0066] With 8% water content, 30% polyester content, 10g waste polyester viscose wool blended fabric containing 15% wool content, placed in 4-methylmorpholine containing 1g propyl gallate and 14% deionized water at 75°C - Swell in 50ml of N-oxide solution for 20min, and then raise the temperature to 90°C to fully dissolve the natural base fibers in it for 80min. The mixture is separated from solid and liquid by vacuum filtration, and the obtained protein / cellulose spinning solution is continuously extruded into water from the spinneret, mechanically stretched 8 times, and regenerated protein / cellulose fibers are obtained, which are recovered and ion exchanged The column was used for purification of 4-methylmorpholine-N-oxide solution containing propyl gallate. The separated solid insoluble matter was immersed in 60ml of butyl benzoate at 190°C for 5 minutes, and then slowly poured into ethanol. When the temperature dropped to 60°C, the separated polyester particles were collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com