Electrical-equipment-quality all-powerful detection station based on modular design

A technology of modular design and power equipment, applied in the direction of measuring electrical variables, measuring electricity, measuring devices, etc., can solve the problems of large hoisting work, high labor costs, single detection items of the detection system, etc., and achieve low system configuration cost, instrument Effect of low acquisition cost and high detection flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

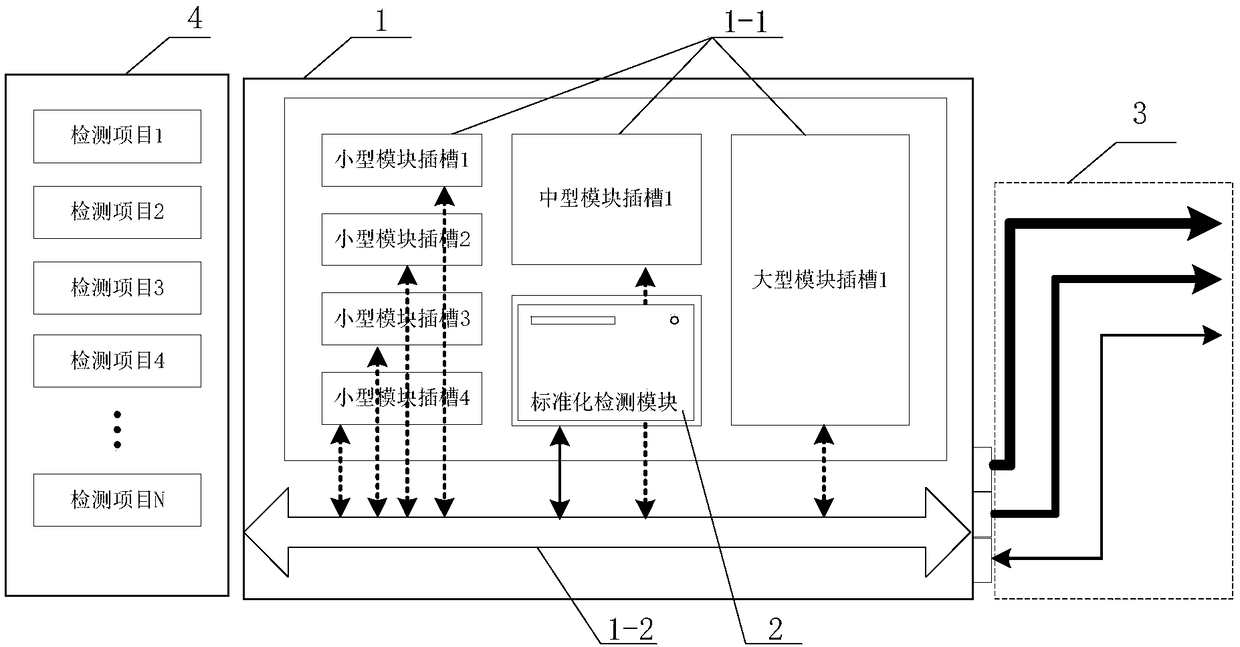

[0047]In this embodiment, various detection instruments are standardized and designed to form a standardized detection module with a specific size and a specific interface. The implementation method is described in detail below, but is not limited to the following implementation methods:

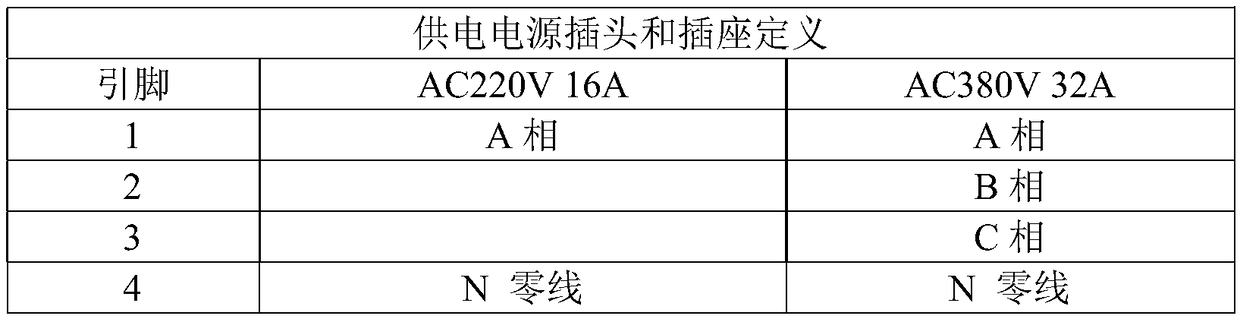

[0048] The standardized detection module of this embodiment is mainly embodied in the standardization of the external structure and the standardization of the electrical connection. In terms of appearance structure, the existing widely used standardized structure is adopted. For some equipment that cannot use the existing standard structure, a new standardized structure design can be carried out to establish a new standardized structure specification. In terms of electrical connection, it is classified by use, and the low-voltage signal class is unified into a group of leads. Select universal standard connectors to realize the ability of quick plugging and unplugging. In terms of power supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com