Bridge-type thermal film microheater, preparation method, and electronic nose array

A technology of micro-heater and hot film, which is applied in the manufacture of semiconductor/solid-state devices, circuits, electrical components, etc. It can solve the problems of thermal insulation and high mechanical strength, poor structural thermal insulation performance, and low yield of micro-heaters, etc. , to achieve the effect of improving electrical conduction rate and yield rate, large size advantage, and size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] 1. Structure

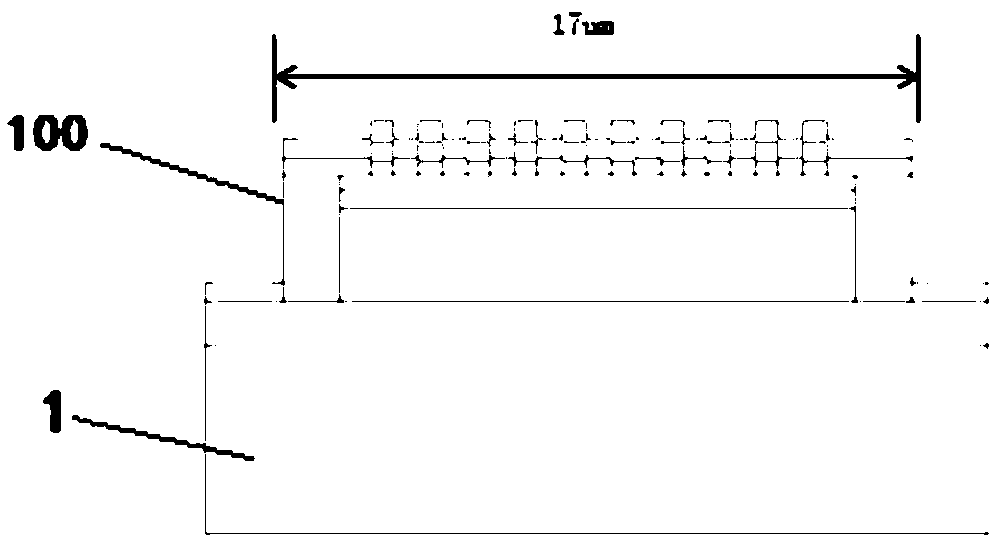

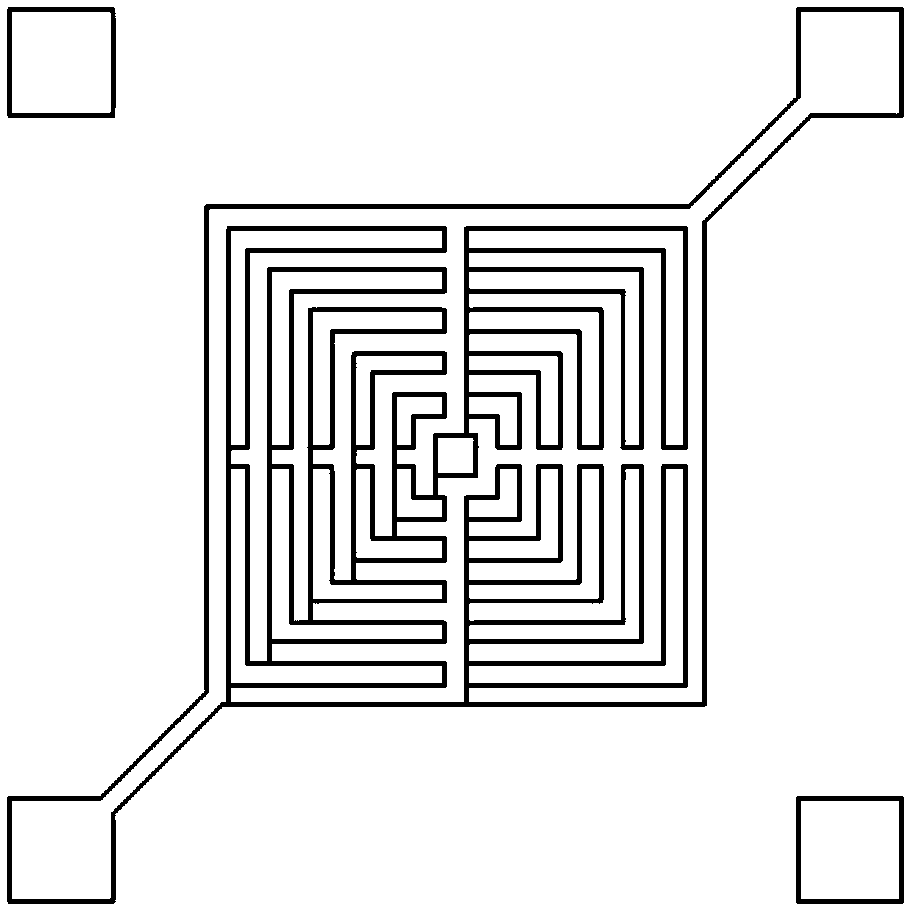

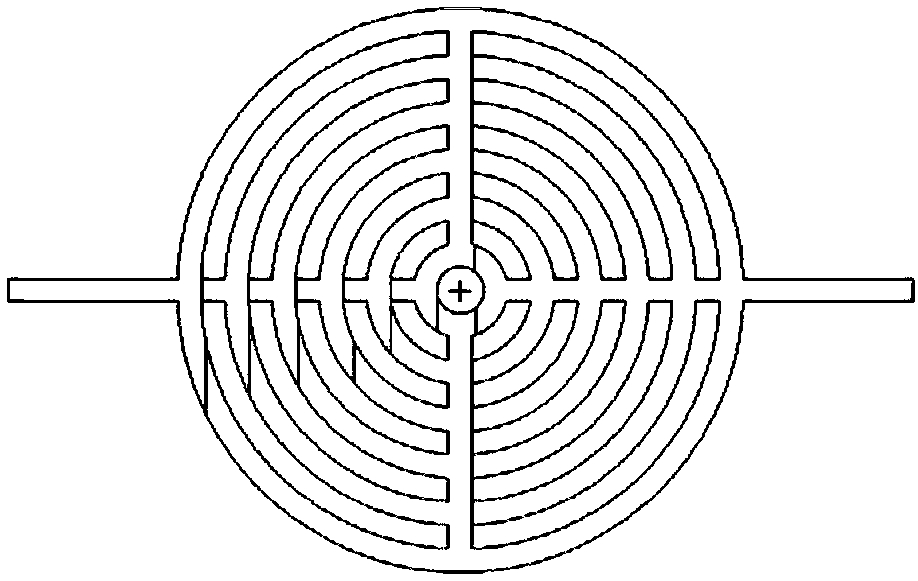

[0061] refer to figure 1 , figure 2 , Figure 22 , the thermal film structure microheater of this embodiment comprises: a thermal insulation layer 2, on the surface of the silicon substrate 1; an insulating layer I3, on the thermal insulation layer 2; an electrode post 4, on the insulating layer I3; The sacrificial layer 5 is used to form the cavity 12 to prepare a suspended heater structure; the supporting layer 6 is located in the area directly above the cavity 12; the insulating layer II7 covers the supporting layer 6; the stepped structure layer 8 is located in the area directly above the insulating layer II7; The heating layer 9 is covered on the composite structure containing the support layer 6, the insulating layer II7, and the stepped structure layer 8, and covers the upper surface of the electrode pillar 4; the passivation layer 10 covers the heating layer 9; the connecting electrode 11 is located at The upper surface of the silicon substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com