Solar photothermal purification method of water based on corncob integral carbon material

A technology of carbon materials and corn cobs, applied in chemical instruments and methods, general water supply conservation, water/sewage treatment, etc., can solve the problems of high cost, complicated preparation process, and no solution proposed, and achieve low cost and simple process Reliable, water-purity inexpensive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for purifying water based on corn cob monolithic carbon material solar light and heat, comprising the following steps:

[0032] 1) Soak a section of corncob in ethanol and distilled water for 6 hours, and then dry it in a vacuum drying oven at 60°C for 24 hours to obtain a dried corncob.

[0033] 2) Put the dried corncobs obtained in step 1) in a tube furnace, raise the temperature to 400°C at a rate of 5°C / min under a nitrogen atmosphere, keep the temperature for 4h, and cool naturally to obtain a monolithic carbon material.

[0034] 3) washing the pyrolysis product obtained in step 2) with ethanol to remove impurities in the pores of the monolithic carbon material;

[0035] 4) The washed product obtained in step 3) was washed three times with deionized water, and the obtained solid was dried in an oven at 60°C for 24 hours to obtain a corncob monolithic carbon material.

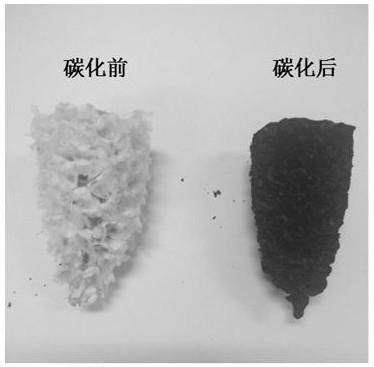

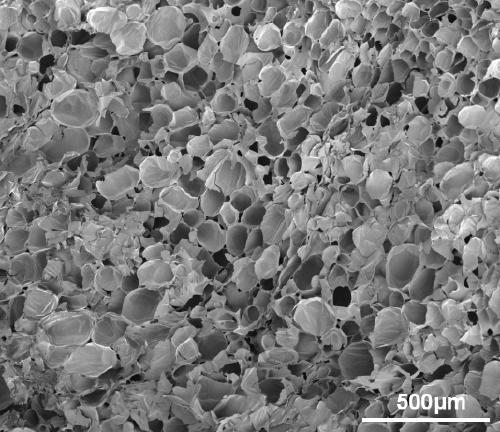

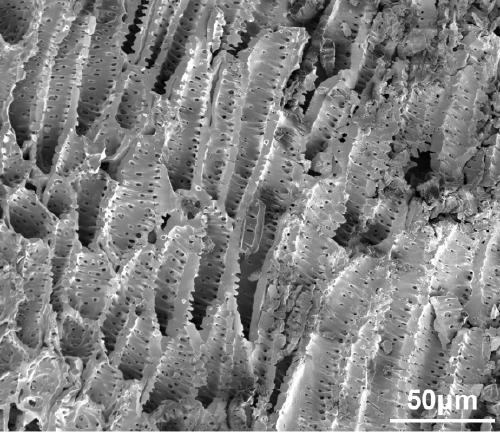

[0036] The digital photo of the corncob used in the present embodiment and its carboniz...

Embodiment 2

[0041] A kind of method based on corncob integral carbon material solar energy photothermal purification dye aqueous solution, comprises the following steps:

[0042] 1) Soak a section of corncob in ethanol and distilled water for 6 hours, and then dry it in a vacuum drying oven at 60°C for 24 hours to obtain a dried corncob.

[0043] 2) Put the dried corn cobs obtained in step 1) into a tube furnace, raise the temperature to 400°C at a rate of 5°C / min under a nitrogen atmosphere, keep the temperature for 4h, and cool naturally to obtain a carbonized product.

[0044] 3) Wash the carbonized product obtained in step 2) with de-ethanol to remove impurities in its pores;

[0045] 4) The washed product obtained in step 3) was washed three times with deionized water, and the obtained solid was dried in an oven at 60°C for 24 hours to obtain a corncob monolithic carbon material.

[0046] The corn cob monolithic carbon material prepared in this embodiment is used for the test of the...

Embodiment 3

[0048] A method for purifying seawater with solar light and heat based on corn cob monolithic carbon material, comprising the following steps:

[0049] 1) Soak a section of corncob in ethanol and distilled water for 6 hours, and then dry it in a vacuum drying oven at 60°C for 24 hours to obtain a dried corncob.

[0050] 2) Put the dried corn cobs obtained in step 1) into a tube furnace, raise the temperature to 400°C at a rate of 5°C / min under a nitrogen atmosphere, keep the temperature for 4h, and cool naturally to obtain a carbonized product.

[0051] 3) Use ethanol to remove the excess by-products in the pores of the carbonized product obtained in step 2);

[0052] 4) The washed product obtained in step 3) was washed three times with deionized water, and then dried in an oven at 60°C for 24 hours to obtain a corncob monolithic carbon material.

[0053] The corn cob water evaporation device prepared in this embodiment is used for the test of seawater evaporation rate, at 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com