Antibacterial thermoplastic polyurethane net film for garments and method for preparing antibacterial thermoplastic polyurethane net film

A thermoplastic polyurethane and antibacterial technology, which is applied in the field of antibacterial thermoplastic polyurethane hot-melt adhesive film for clothing and its preparation, can solve the problem that the thermoplastic polyurethane film cannot have both antibacterial and adhesive properties, and is difficult to meet the needs of applications in related fields. and other problems, to achieve the effect of excellent antibacterial effect, good adhesive strength and excellent antibacterial property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

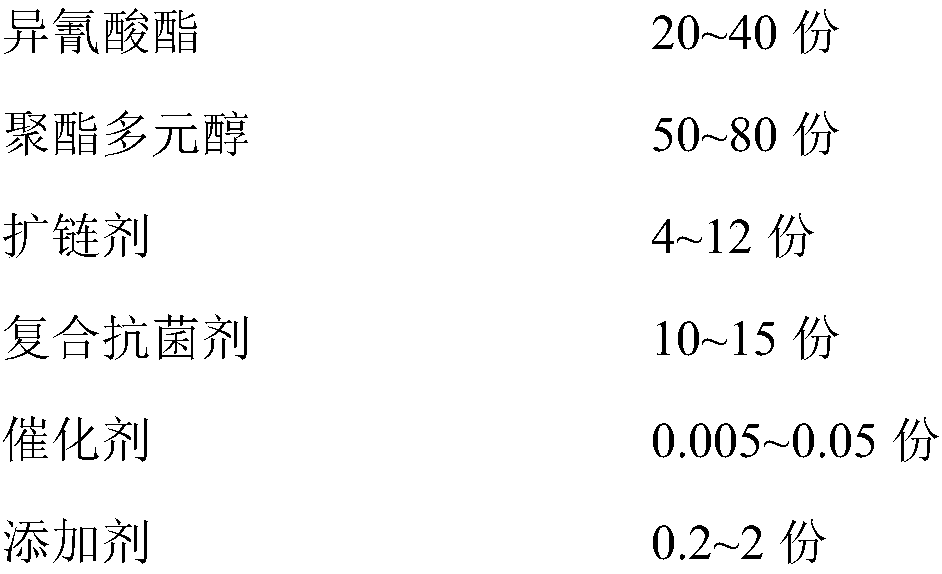

Method used

Image

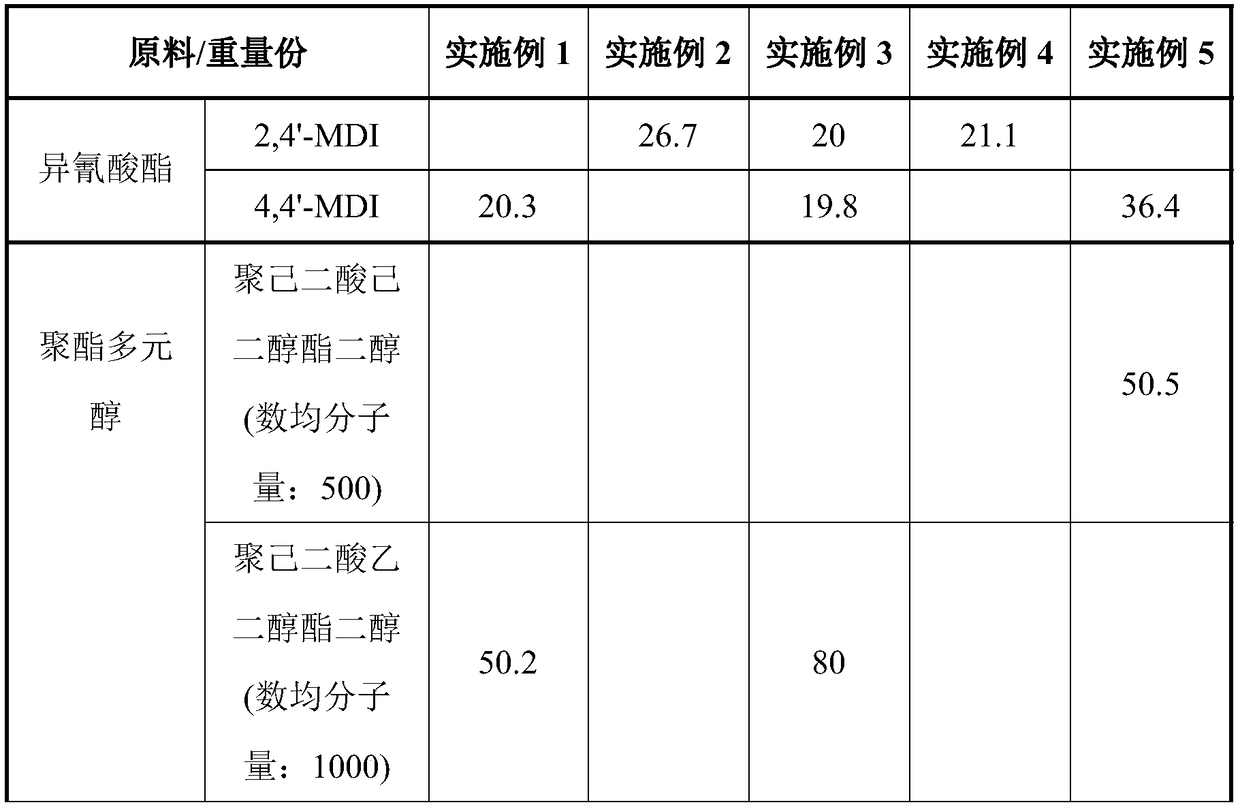

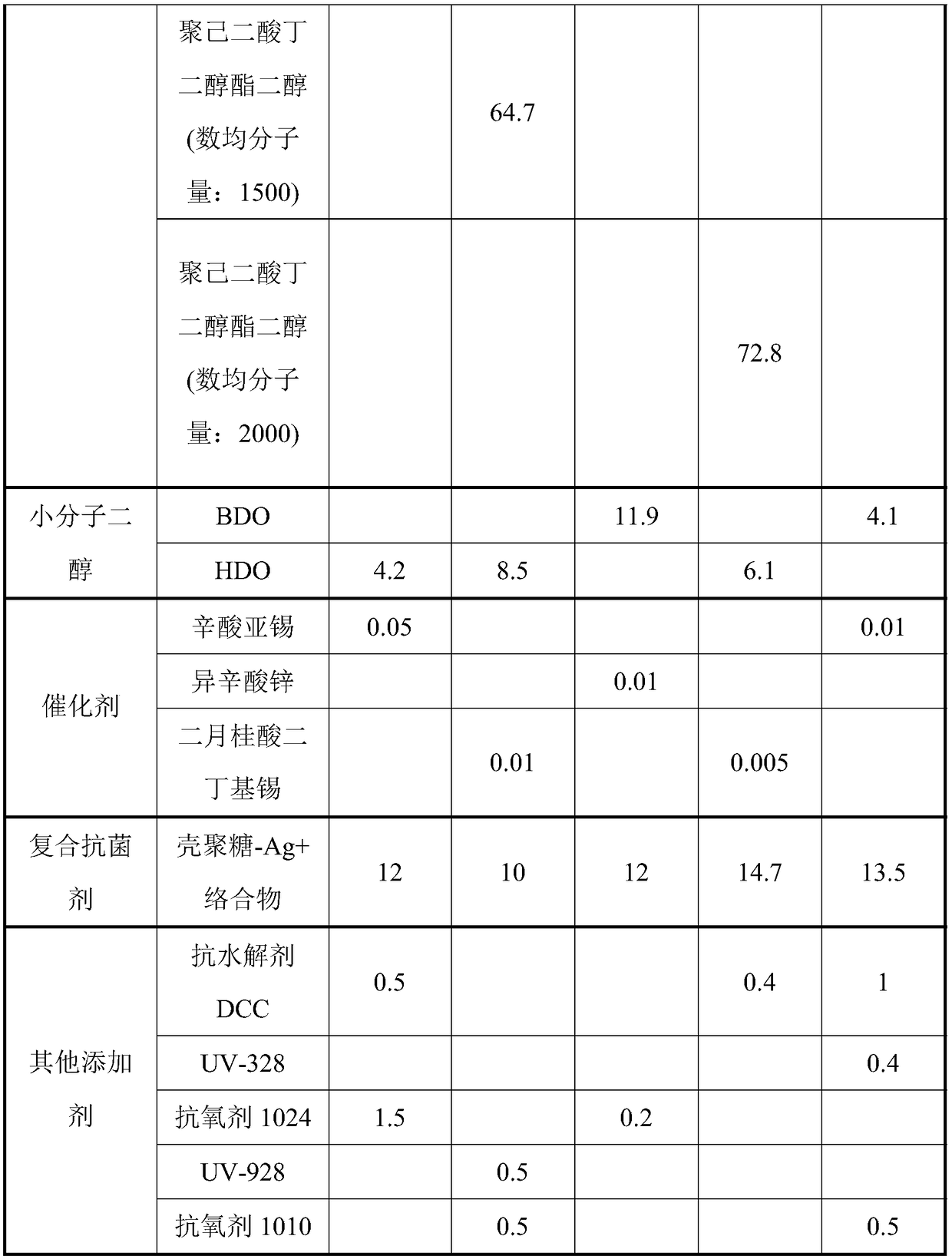

Examples

preparation example Construction

[0029] (1) Chitosan-Ag + Preparation of the complex:

[0030] The chitosan of 10 mass parts (molecular weight 100,000 g / mol, degree of deacetylation 90%, Zhengzhou Givaudan Chemical Products Co., Ltd.) is added in the mass concentration of 100 mass parts in the acetic acid solution of 3%, at 60 ℃ constant temperature Heat on a water bath until the solution is completely dissolved, and the resulting solution is separated to remove impurities. Chitosan acetic acid solution was under nitrogen protection, adding 1mol / L sodium hydroxide aqueous solution to adjust the pH value to be neutral; 0.2 mass parts of silver nitrate (Suzhou Fulu Biotechnology Co., Ltd.) was added after 30 minutes, and stirred at a constant temperature of 60°C React for 5 hours; wash by centrifugation, and vacuum-dry at 70°C for 24 hours to obtain the chitosan-Ag+ complex, which is set aside.

[0031] (2) Preparation of antibacterial thermoplastic polyurethane omentum for clothing:

[0032] The raw materia...

Embodiment 1

[0041]According to the mass parts of each raw material component in Example 1 shown in Table 1, the polyester polyol and additives were fully blended and heated to 110°C; the diisocyanate was heated to 55°C and kept; the chain extender was heated to 60°C and kept. Add the heated raw material components to the twin-screw extruder through the mixing and feeding system at a rate of 250-300kg / h, add the catalyst at the injection port of the twin-screw extruder, and add shell poly Sugar-Ag+ complex, each component is co-polymerized by the screw, and then dried under water to obtain antibacterial thermoplastic polyurethane for clothing web.

[0042] Among them, the screw temperature is 160°C, the screw speed is 80rpm, and the twin-screw aspect ratio is 40:1;

[0043] The temperature of the die head is 150°C, the water temperature of the pelletizing system is controlled at 0°C, and the speed of the underwater pelletizer is controlled at 2000rpm.

Embodiment 2

[0045] According to the mass parts of each raw material component in Example 2 shown in Table 1, the polyester polyol and additives were fully blended and heated to 110°C; the diisocyanate was heated to 55°C and kept; the chain extender was heated to 60°C and kept. Add the heated raw material components to the twin-screw extruder through the mixing and feeding system at a rate of 250-300kg / h, add the catalyst at the injection port of the twin-screw extruder, and add shell poly Sugar-Ag+ complex, each component is co-polymerized by the screw, and then dried under water to obtain antibacterial thermoplastic polyurethane for clothing web.

[0046] Among them, the screw temperature is 140°C, the screw speed is 130rpm, and the twin-screw aspect ratio is 45:1;

[0047] The temperature of the die head is 130°C, the water temperature of the pelletizing system is controlled at 5°C, and the speed of the underwater pelletizer is controlled at 1500rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com