A breakdown-resistant led light panel

A technology of LED light board and LED aluminum substrate, which is applied in the direction of adhesive types, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., can solve the problems of limiting the service life of LED light boards, and achieve excellent breakdown resistance, Good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

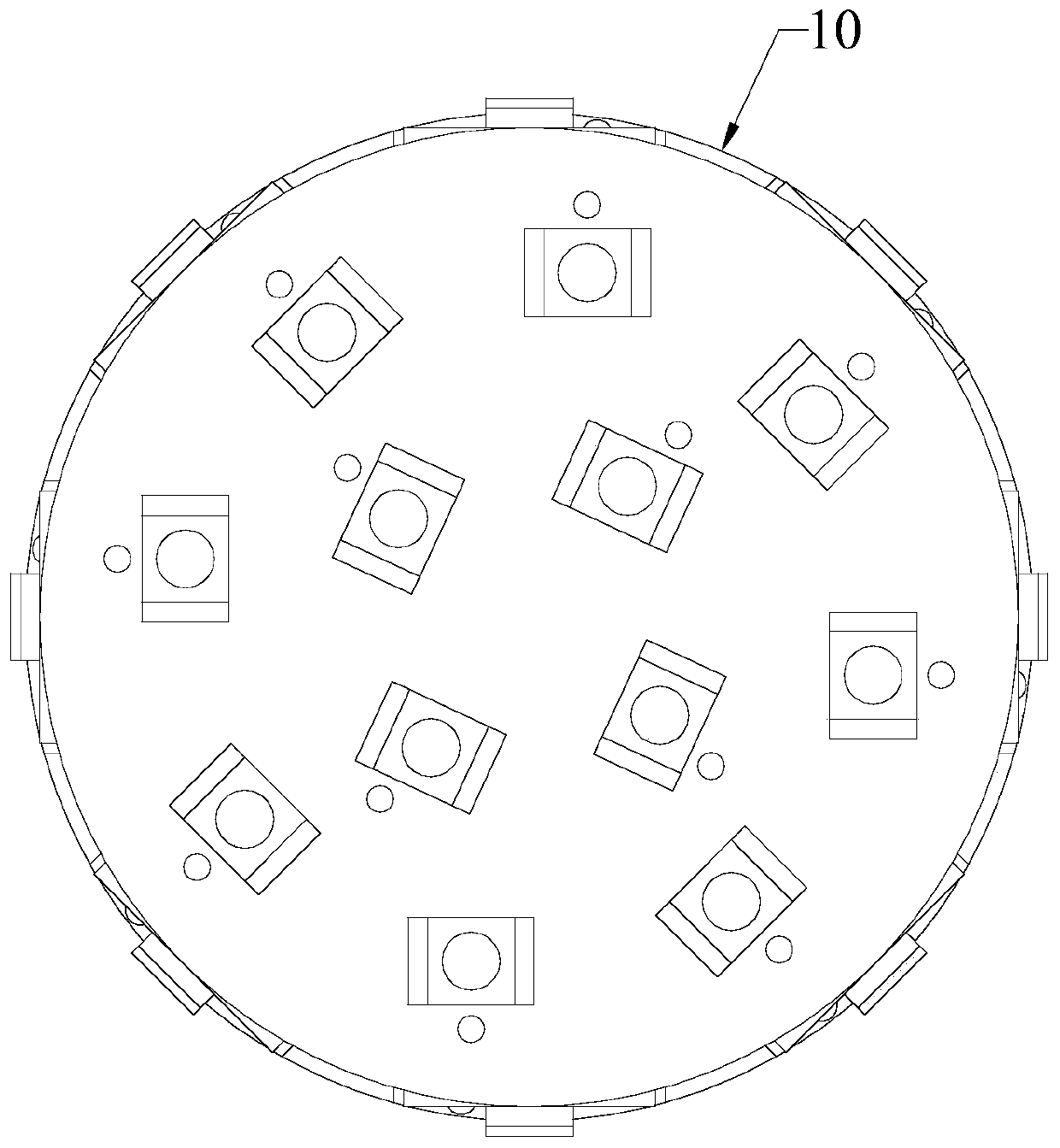

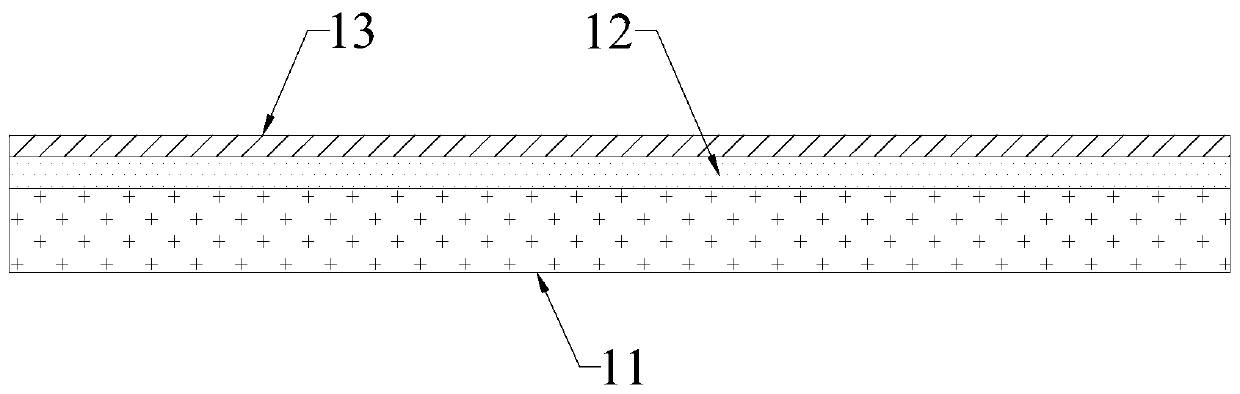

[0019] Such as Figure 1~2 As shown, the breakdown-resistant LED lamp panel includes an LED aluminum substrate 10, the LED aluminum substrate 10 includes an aluminum layer 11 and a circuit layer 13, and a breakdown-resistant Type insulating layer 12.

[0020] Prepare epoxy resin adhesive in a closed stirring tank, mix and stir 100kg epoxy resin, 3.5kg tertiary amine curing agent, 1.2kg imidazole accelerator, 2.9kg silane coupling agent, 80kg thermal conductive filler, 40kg solvent to form a ring Oxygen resin adhesive. Then, ozone was introduced into the stirring tank to stir to form the first glue solution, and the mass ratio between the ozone and the epoxy resin adhesive was 0.75:1000. After introducing ozone into the stirred tank, the temperature inside the stirred tank was raised to 50° C. and stirred at this temperature for 60 minutes to prepare the first glue solution.

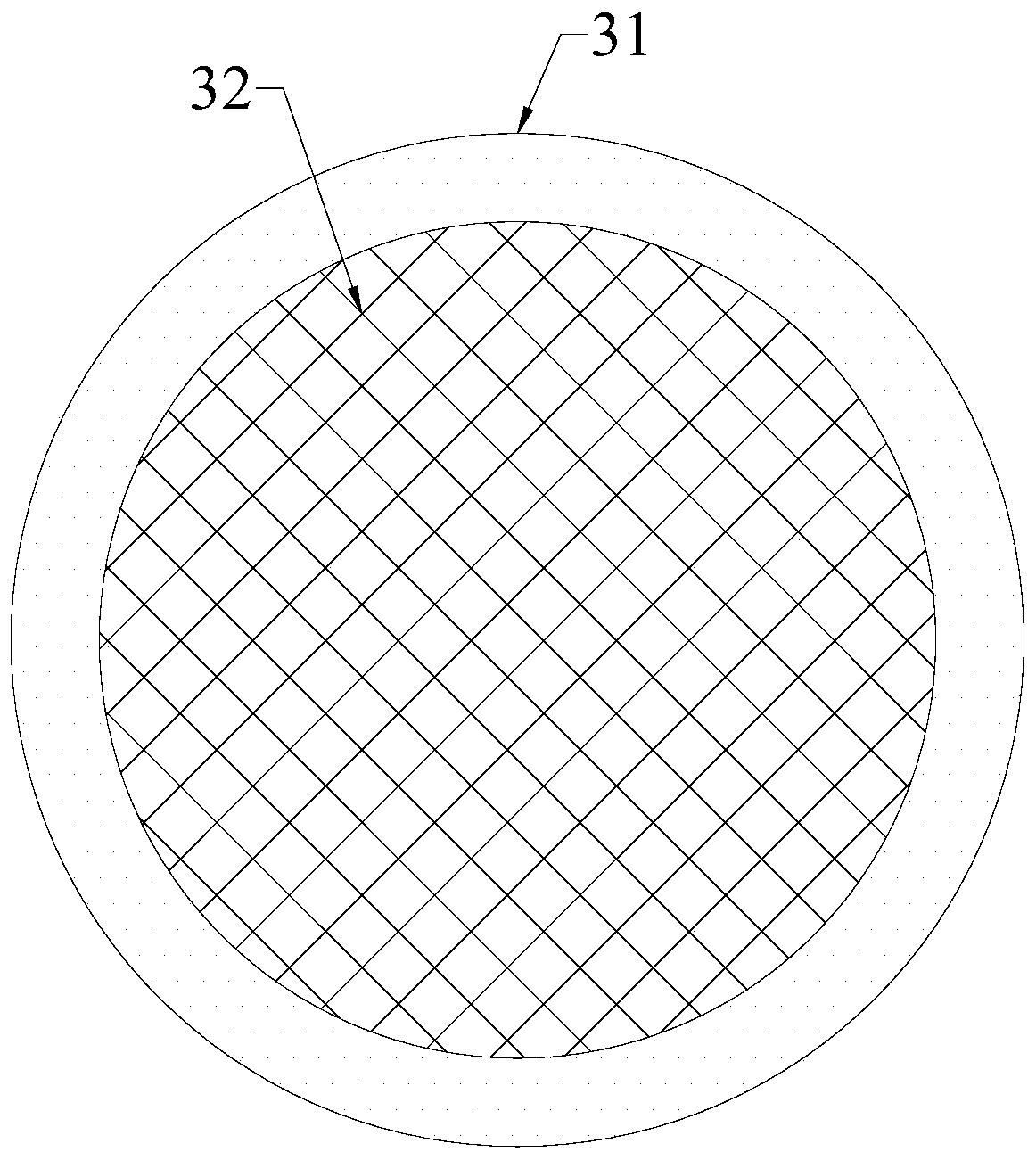

[0021] Such as image 3 As shown, the magnetic filter includes an annular electromagnet 31, and th...

Embodiment 2

[0025] The structure of the breakdown-resistant LED lamp panel in this embodiment is the same as that of the breakdown-resistant LED lamp panel in Embodiment 1. The structure of the magnetic filter in this embodiment is the same as that of the magnetic filter in Embodiment 1.

[0026] Prepare epoxy resin adhesive in a closed stirring tank, mix and stir 110kg epoxy resin, 4kg tertiary amine curing agent, 1.5kg imidazole accelerator, 3kg silane coupling agent, 90kg thermal conductive filler, and 50kg solvent to make epoxy resin adhesive. Then, ozone was introduced into the stirring tank to stir to form the first glue solution, and the mass ratio between the ozone and the epoxy resin adhesive was 0.9:1000. After introducing ozone into the stirred tank, the temperature inside the stirred tank was raised to 53° C. and stirred at this temperature for 66 minutes to prepare the first glue solution.

[0027] The first glue solution is filtered by a magnetic filter to obtain the secon...

Embodiment 3

[0030] The structure of the breakdown-resistant LED lamp panel in this embodiment is the same as that of the breakdown-resistant LED lamp panel in Embodiment 1. The structure of the magnetic filter in this embodiment is the same as that of the magnetic filter in Embodiment 1.

[0031] Prepare epoxy resin adhesive in a closed stirring tank, mix and stir 120kg epoxy resin, 4.3kg tertiary amine curing agent, 1.6kg imidazole accelerator, 3.6kg silane coupling agent, 95kg thermal conductive filler, and 55kg solvent to form a ring Oxygen resin adhesive. Then pass ozone into the stirring tank and stir to make the first glue solution, the mass ratio between the ozone and the epoxy resin adhesive is 1:1000. After introducing ozone into the stirred tank, the temperature inside the stirred tank was raised to 55° C. and stirred at this temperature for 60 minutes to prepare the first glue solution.

[0032] The first glue solution is filtered by a magnetic filter to obtain the second glu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breakdown voltage | aaaaa | aaaaa |

| breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com