Incident angle-insensitive color filter based on porous alumina and preparation method thereof

A technology of porous alumina and color filters, applied in the field of filters, can solve problems such as affecting the display performance of the spectral curve of the filters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

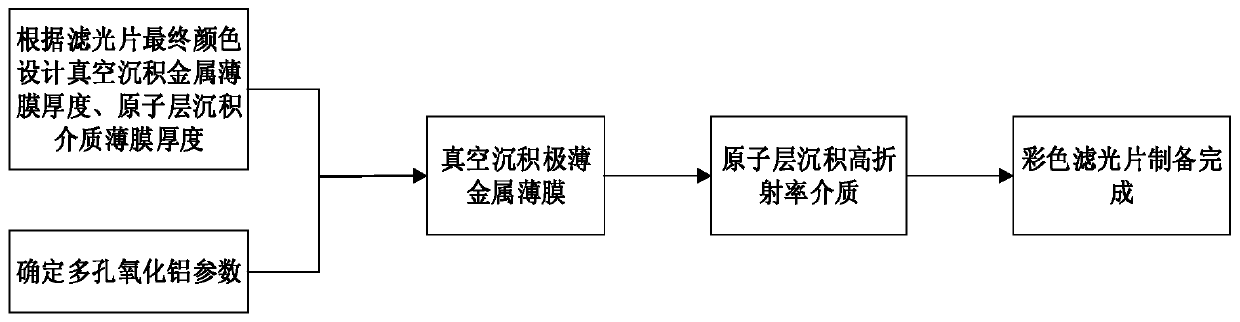

[0054] The preparation process of angle-insensitive color filters is as follows: figure 2 shown, including:

[0055] 1) For the selected cyan-magenta yellow (CMY) spectrum, according to the color of the final filter, determine the parameters of porous alumina and design the thickness of the vacuum thermally deposited metal layer and the thickness of the atomic layer deposition high refractive index medium;

[0056] 2) placing the substrate with porous alumina in a vacuum coating device, controlling the deposition parameters, and depositing the metal film obtained in step 1) on the substrate;

[0057] 3) Take out the metal-coated substrate from the vacuum coating equipment, and calculate the number of coating cycles according to the thickness of the high-refractive-index dielectric layer designed in step 1); control the parameters using atomic layer deposition technology, and plate a thin film with a corresponding number of cycles.

Embodiment 1

[0059] Angle-insensitive cyan filter:

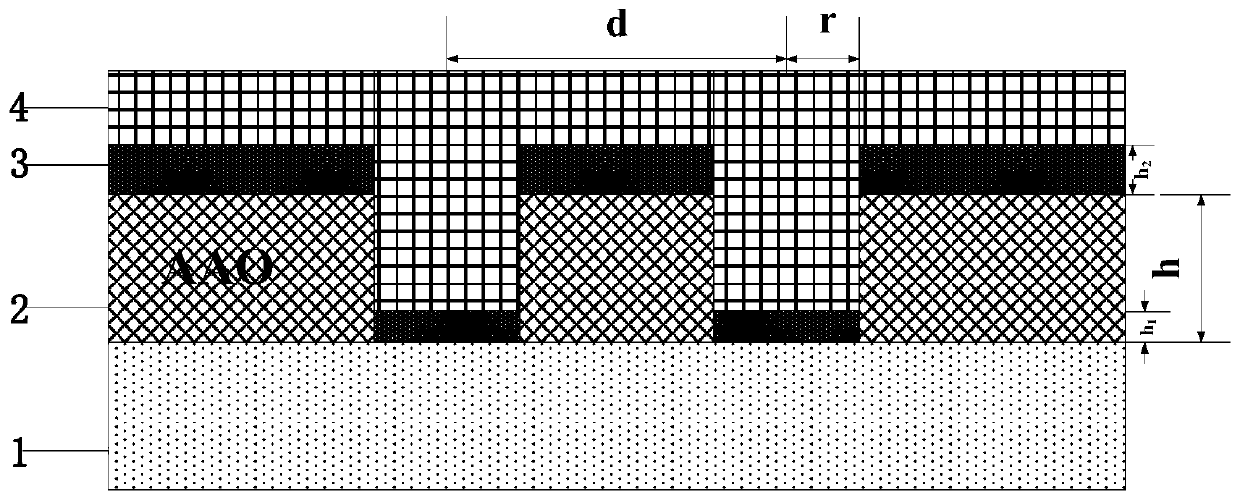

[0060] The structure of the filter is as figure 1 As shown, it includes the substrate and the porous alumina attached to the substrate, the metal layer and the high refractive index dielectric layer. The metal material is aluminum, the high refractive index material is titanium dioxide, and the base material is fused silica glass. The parameters used to prepare each part are as follows:

[0061]

[0062] When plating the metal aluminum layer, control the vacuum degree of the evaporation chamber to be lower than 3×10 -3 Pa, the substrate temperature is 27°C, during evaporation, the evaporation rate is controlled to be stable at 0.1nm / s; when titanium oxide is plated, the vacuum degree of the reaction chamber is controlled at 3mbar, the base temperature is 120°C, and the precursor passes through each cycle. The injection time is 300ms, and the nitrogen purge time is 4s.

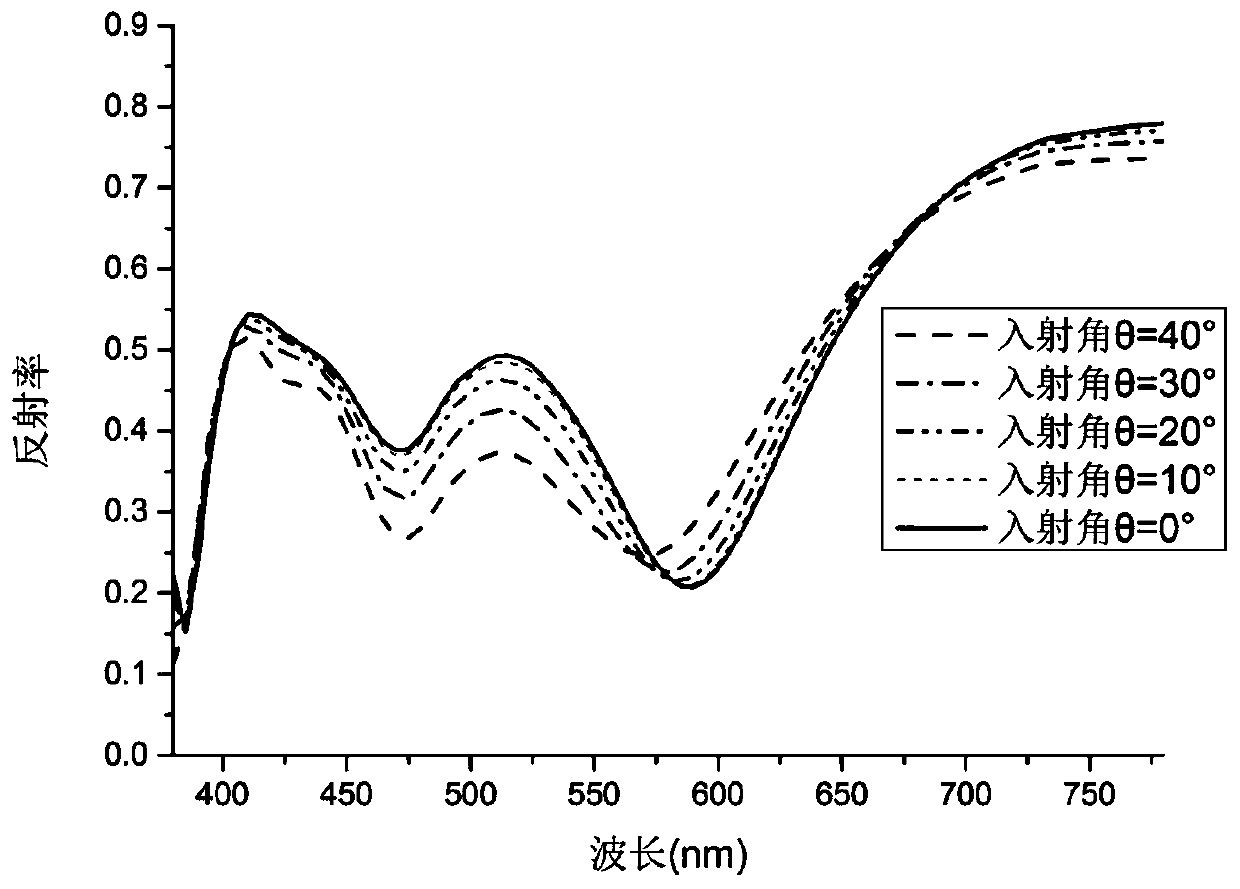

[0063] The reflection spectra of the prepared cyan angle-inse...

Embodiment 2

[0065] Angle-insensitive magenta filters:

[0066] The structure of the filter is as figure 1 As shown, it includes the substrate and the porous alumina attached to the substrate, the metal layer and the high refractive index dielectric layer. The metal material is aluminum, the high refractive index material is titanium dioxide, and the base material is fused silica glass. The parameters used to prepare each part are as follows:

[0067]

[0068] When plating the metal aluminum layer, control the vacuum degree of the evaporation chamber to be lower than 3×10 -3 Pa, the substrate temperature is 27°C, during evaporation, the evaporation rate is controlled to be stable at 0.1nm / s; when titanium oxide is plated, the vacuum degree of the reaction chamber is controlled at 3mbar, the base temperature is 120°C, and the precursor passes through each cycle. The injection time is 300ms, and the nitrogen purge time is 4s.

[0069] The reflection spectrum of the prepared magenta an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com