Monatomic iron-based carbon material and preparation method and electrocatalytic application thereof

A carbon material, iron-based technology, used in circuits, electrical components, battery electrodes, etc., can solve the problems of complex process, low product yield, poor controllability of product morphology, etc., and achieves simple synthesis means and preparation technology. Simple, highly repeatable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

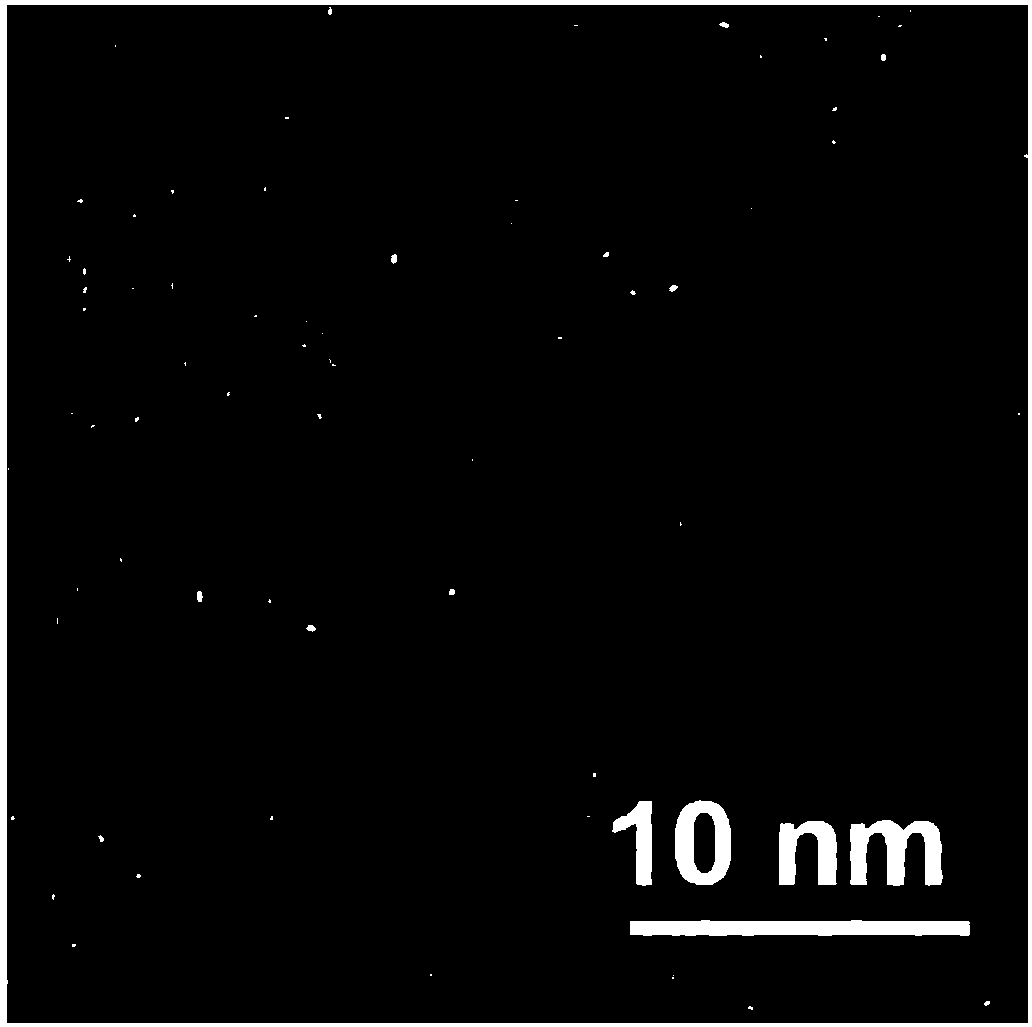

[0038] Weigh 60mg of ferric ammonium citrate and dissolve it in 20mL of deionized water, then add 1.0g of ZIF-7, stir vigorously for 16 hours, centrifuge, wash and dry to obtain a yellow powder, then place 0.5g of the yellow powder in a horizontal Tube furnace, in argon atmosphere 50mL min -1 At flow rate, at 3°C min -1 Raise the temperature to 600°C and keep it for 2 hours, then take it out after naturally cooling to room temperature. The resulting black solid was dissolved in 0.5mol L -1 HClO 4 solution, treated at 80°C for 10 hours, filtered, washed and dried to obtain a monoatomic iron-based carbon material with a product yield of 65%. The electron microscope appearance of the catalyst is as follows: figure 1 As shown in the figure, the product in this example does not have iron nanoparticles to generate, which proves that the anchoring effect of ZIF-7 on ferric ammonium citrate effectively avoids the accumulation of iron elements in the pyrolysis process, so that the...

Embodiment 2

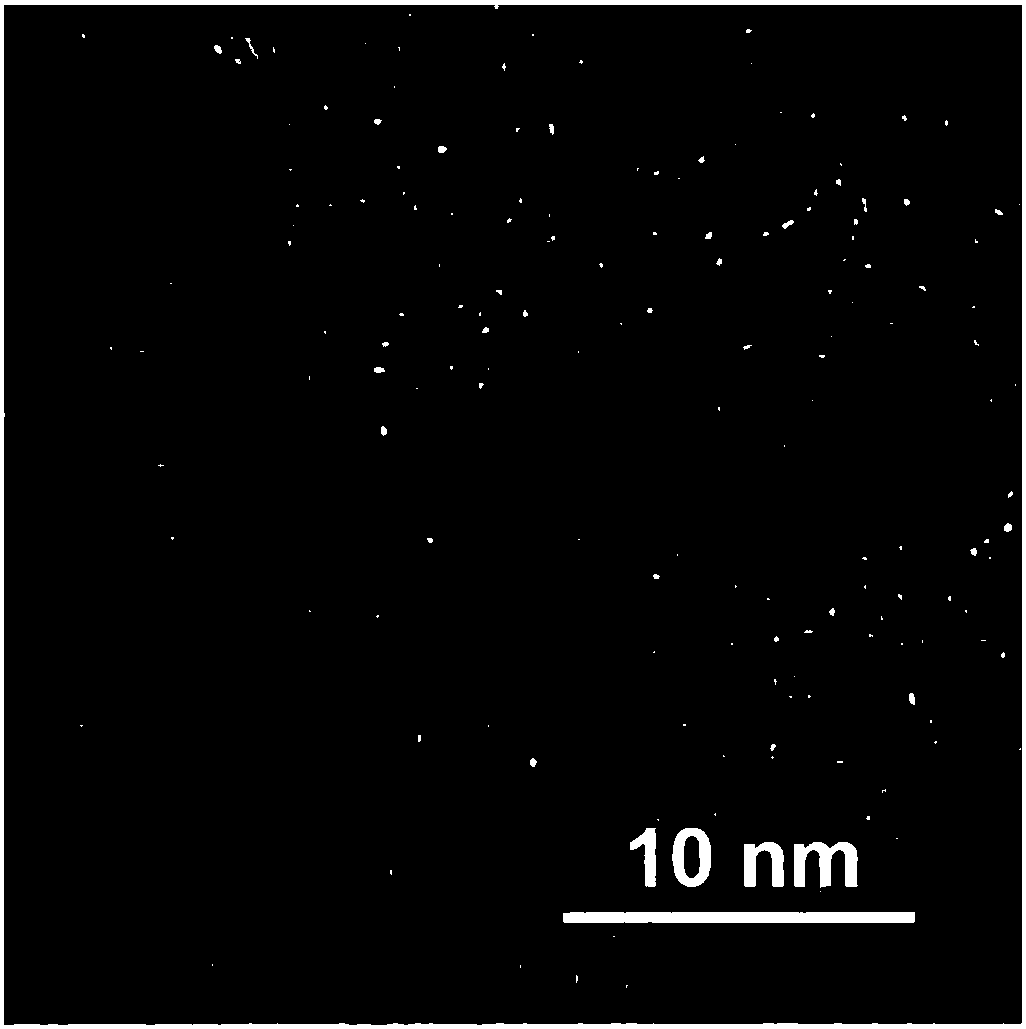

[0041] Weigh 240 mg ferric ammonium citrate and dissolve it in 20 mL deionized water, then add 1.0 g ZIF-7, stir vigorously for 4 hours, centrifuge, wash and dry to obtain a yellow powder. Then 0.6g of yellow powder was placed in a horizontal tube furnace equipped with a quartz tube, in a helium atmosphere of 30mL min -1 At flow rate, at 5°C min -1 Raise the temperature to 900°C and keep it for 4 hours, then take it out after naturally cooling to room temperature. The resulting black solid was dissolved in 3mol L -1 h 2 SO 4 solution, treated at 70°C for 8 hours, filtered and washed with water, and dried to obtain a monoatomic iron-based carbon material catalyst with a product yield of 53%. The electron microscope appearance of the catalyst is as follows: image 3 It can be seen that even in the case of high ferric ammonium citrate feed, the molecular level dispersion of iron element can still be achieved, and the mass fraction of iron element corresponding to the catalyst...

Embodiment 3

[0043] Weigh 12 mg of ferric ammonium citrate and dissolve it in 20 mL of deionized water, then add 1.0 g of ZIF-7, stir vigorously for 24 hours, then centrifugally wash and dry to obtain a yellow powder. Then 0.5g of yellow powder was placed in a horizontal tube furnace equipped with a quartz tube, in a nitrogen atmosphere of 100mL min -1 At flow rate, at 3°C min -1 Raise the temperature to 1100°C and keep it for 6 hours, then take it out after naturally cooling to room temperature. The resulting black solid was dissolved in 0.1mol L -1 HClO 4 solution, treated at 70°C for 12 hours, filtered, washed and dried to obtain a monoatomic iron-based carbon material with a product yield of 45%. The electron microscope appearance of the catalyst is as follows: Figure 4 As shown, although the pyrolysis temperature is as high as 1100 ° C, no iron nanoparticles appear, and the white bright spots in the figure illustrate the uniform dispersion of metal species, that is, the method p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com