Preparation method for microcapsule-coated insecticide controlled release textile

A technology of microcapsules and insecticides is applied in the field of preparation of microcapsule-coated insecticide controllable release textiles. Research and other issues to achieve the effect of good anti-mosquito and anti-mosquito effect, long-term anti-mosquito and anti-mosquito effect, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

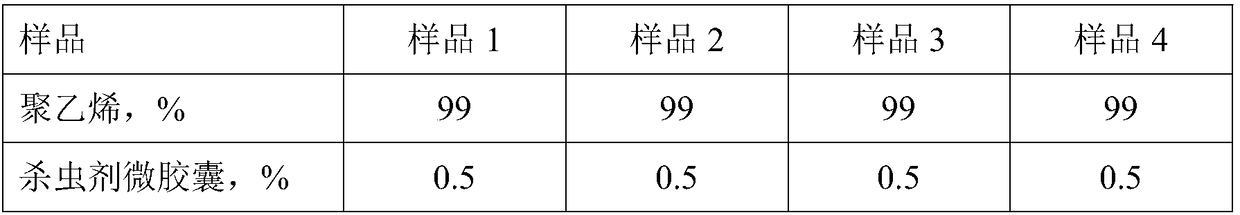

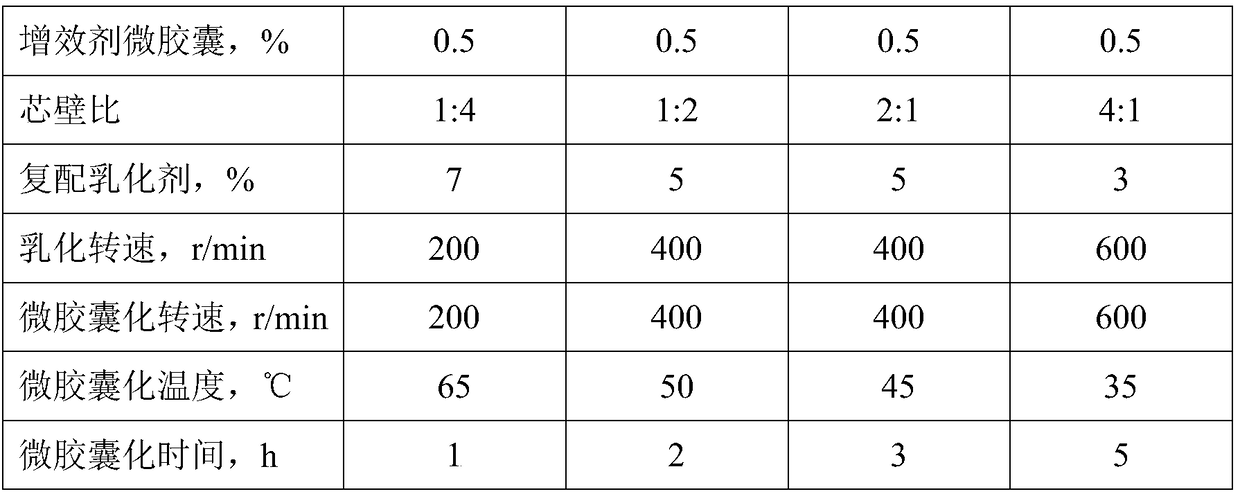

[0041] The production raw materials include polyethylene, insecticide microcapsules (containing deltamethrin) and synergist microcapsules (containing butyronyl ether), and the content percentage of each raw material is:

[0042] Polyethylene: 99%; the content ratio of HDPE to LDPE is 3:1.

[0043] Insecticide microcapsules (containing deltamethrin): 0.5%; prepared by interfacial polymerization with deltamethrin as the core material and polyurea as the wall material, with an average particle size of 4 μm and a core-to-wall ratio of 1:4 - Microencapsulated particles between 4:1. The specific preparation method of insecticide microcapsules is as follows:

[0044] a) Oil phase preparation: fully dissolve 0.1%-0.4% deltamethrin in cyclohexanone, add toluene-2,4-diisocyanate and mix evenly;

[0045] b) Water phase preparation: disperse 3%-7% compound emulsifier into deionized water, and make emulsifier / water system under high shear rate;

[0046] c) emulsification: adding the oil...

Embodiment 2

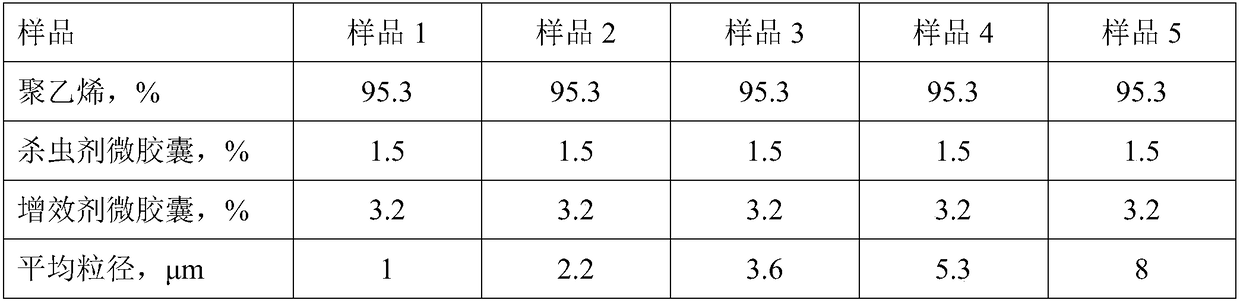

[0062] The production raw materials include polyethylene, insecticide microcapsules (containing deltamethrin) and synergist microcapsules (containing butyronyl ether), and the content percentage of each raw material is:

[0063] Polyethylene: 95.3%; the content ratio of HDPE to LDPE is 30:1.

[0064] Insecticide microcapsules (containing deltamethrin): 1.5%; adopt the interfacial polymerization method described in Example 1 to prepare respectively with deltamethrin as the core material, polyurea as the wall material, and the ratio of core to wall is 1:2 , microcapsule particles with an average particle size between 1-8 μm.

[0065] Synergist microcapsules (containing synergistic ether): 3.2%; adopt the interfacial polymerization method described in Example 1 to prepare respectively with synergistic ether as the core material, polyurea as the wall material, and the core-to-wall ratio is 1:2, the average Microcapsule particles with a particle size between 1-8 μm.

[0066] The ...

Embodiment 3

[0076] The production raw materials include polyethylene, insecticide microcapsules (containing deltamethrin) and synergist microcapsules (containing butyronyl ether), and the content percentage of each raw material is:

[0077] Polyethylene: 96.8%; the content ratio of HDPE to LLDPE is 30:1.

[0078] Insecticide microcapsules (containing deltamethrin): 1.1%; the interfacial polymerization method described in Example 1 is used to prepare polyurethane as the wall material, and deltamethrin is the microcapsule of the core material, and its average particle diameter is 4.8 μm, the core-to-wall ratio is 2:1. The specific preparation method is:

[0079] a) Oil phase preparation: fully dissolve 0.73% deltamethrin in cyclohexanone, add toluene-2,4-diisocyanate and mix evenly;

[0080]b) Water phase preparation: disperse 5% of the compound emulsifier into deionized water, and make an emulsifier / water system at a high shear rate;

[0081] c) emulsification: adding the oil phase of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com