Plant fruit thinning agent and plant fruit thinning method

A plant and fruit technology, applied in the directions of botanical equipment and methods, plant growth regulators, plant growth regulators, etc., can solve the negative impact of air quality and environmental sanitation, affect the growth and ornamental value of ginkgo trees, and increase the burnt edge of ginkgo biloba Disease incidence and other issues, to achieve the effect of plant safety, economical and practical, easy to promote and use on a large scale, and to avoid the weakening of plant vigor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

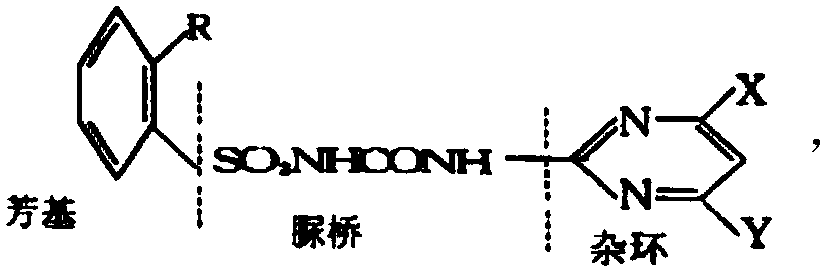

[0041] The original drug and auxiliary agents are compounded into 20% wettable powder, wherein the original drug includes forchlorfenuron, triiodobenzoic acid, 3-(4,6-dimethoxy Pyrimidin-2-yl)-1-(2-methoxyformylbenzyl) sulfonylurea, auxiliary agent selects NP10, white carbon black, kaolin, and the percentages by weight of each component are as follows: original drug 20%, NP10 10%, white carbon black 15%, and kaolin to make up to 100%. The preparation process is to mix each component uniformly in a double-screw mixer according to weight percentage, and then pulverize it through an ultrafine pulverizer or jet pulverizer to control the particle size less than 325 mesh (wet sieving method), and then mix evenly in another double-screw mixer to obtain 20% wettable powder.

Embodiment 2

[0043] The original drug 6-benzyl adenine, chlorphenamine, and cycloheximide are dissolved in absolute ethanol at a weight ratio of 1:1:3 to prepare a 5% solution.

Embodiment 3

[0045] The original drug and auxiliary agents are compounded into 20% wettable powder, wherein the original drug includes indole ester, 2,4-dichlorophenoxyacetic acid, 2-chloroethyl Trimethylammonium chloride, ethyl 5-(4,6-dimethyloxypyrimidin-2-ylcarbamoylsulfamoyl-1-methylpyrazole-4-carboxylate, NP10, white carbon as additives Black, kaolin, the percentages by weight of each component are as follows: 20% of the original drug, 10% of NP10, 15% of white carbon black, and kaolin is added to 100%. The preparation process is to mix each component by weight percentage in a double-screw mixer After mixing evenly, pulverize with an ultrafine pulverizer or jet mill to control the particle size to be less than 325 mesh (wet sieving method), and then mix evenly in another double-screw mixer to obtain a 20% wettable powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com