Feed additive for reducing astringency of goat meat and preparation method thereof

A feed additive, goat meat technology, applied in the molding or processing of animal feed, animal feed, animal feed, etc., can solve the problems of goat meat odor and taste can not be achieved, achieve tender and safe meat, promote dirt excretion, improve The effect of anti-aging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

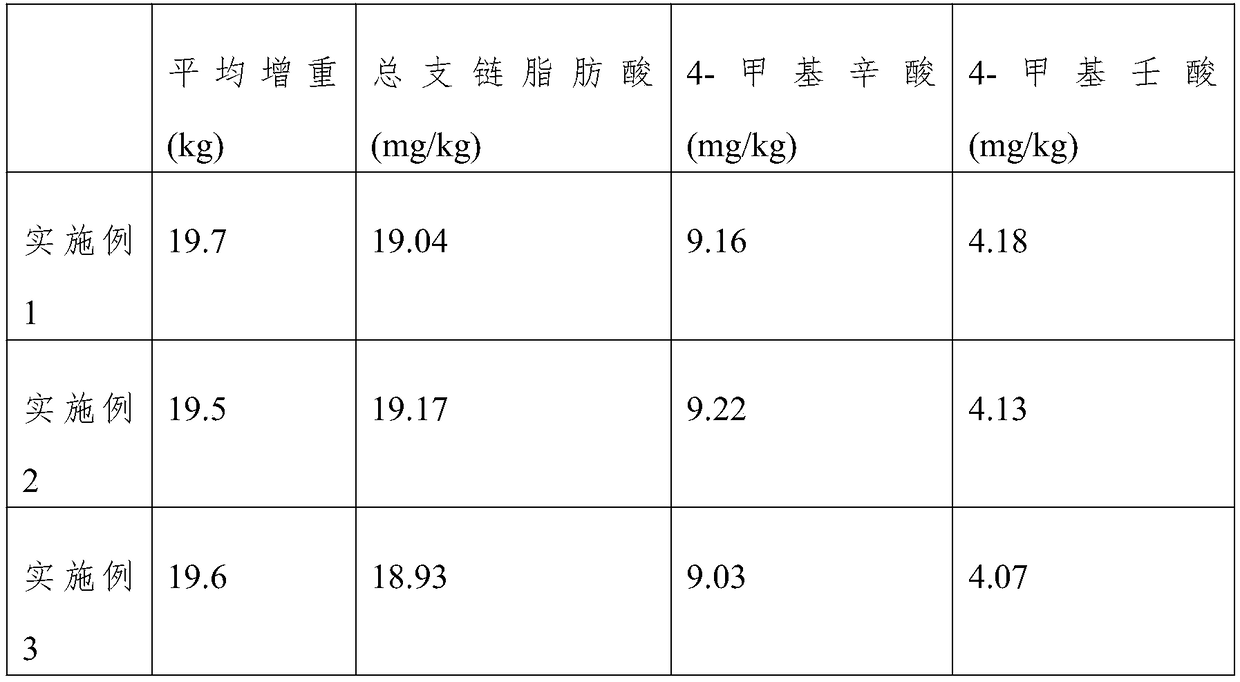

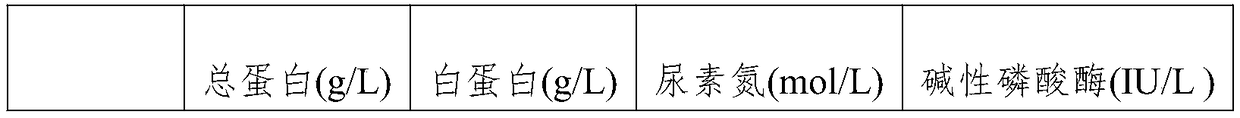

Embodiment 1

[0023] A preparation method of a feed additive for reducing the smell of goat meat, comprising 10kg of butter, 66kg of shrimp shell powder, 6kg of fragrant tea, 0.2kg of EM bacteria, 20kg of bone meal, 20kg of seaweed, 9kg of modified starch, and 9kg of Chinese medicine extract 1. Pretreat 4kg of sludge at the bottom of the pond, stir for 20min at a temperature of 80°C and a rotation speed of 180r / min, place it at a temperature of 5°C for 2h, and then grind to pass 200 mesh;

[0024] The modified starch is mixed with starch, calcium lactate, and water in a mass ratio of 46:1:170, and starts to heat up. When the temperature rises to 87° C., react for 35 minutes; add titanium powder with an amount of calcium lactate of 0.5, and continue The temperature rises to 99°C, reacts for 30 minutes, irradiates with ultraviolet light for 10 minutes, cools down and discharges;

[0025] The starch is corn starch, wheat starch, rice starch, potato starch, potato starch, tapioca starch or any ...

Embodiment 2

[0031] A preparation method of a feed additive for reducing the smell of goat meat, comprising 5 kg of butter, 56 kg of shrimp shell powder, 3 kg of fragrant tea, 0.1 kg of EM bacteria, 10 kg of bone meal, 10 kg of seaweed, 5 kg of modified starch, and 5 kg of Chinese medicine extract 1. Stir 1 kg of pretreated bottom sludge at a temperature of 60°C and a rotation speed of 150r / min for 15 minutes, place it at a temperature of 0°C for 1 hour, and then grind to pass 200 mesh;

[0032] The modified starch is mixed with starch, calcium lactate, and water in a mass ratio of 40:1:150, and starts to heat up. When the temperature rises to 80° C., react for 30 minutes; add titanium powder with an amount of calcium lactate of 0.1, and continue The temperature rises to 96°C, reacts for 20 minutes, irradiates with ultraviolet light for 5 minutes, cools down and discharges;

[0033] The starch is corn starch, wheat starch, rice starch, potato starch, potato starch, tapioca starch or any tw...

Embodiment 3

[0039]A preparation method of a feed additive for reducing the smell of goat meat, comprising 7kg of butter, 60kg of shrimp shell powder, 5kg of fragrant tea, 0.15kg of EM bacteria, 15kg of bone meal, 15kg of seaweed, 7kg of modified starch, and 7kg of Chinese medicine extract 1. Pretreat 3kg of sludge at the bottom of the pond, stir for 18 minutes at a temperature of 70°C and a rotation speed of 165r / min, place it at a temperature of 4°C for 1 hour, and then grind to pass 200 mesh;

[0040] The modified starch is mixed with starch, calcium lactate, and water in a mass ratio of 45:1:160, and starts to heat up. When the temperature rises to 85° C., react for 30 minutes; add titanium powder with an amount of calcium lactate of 0.2, and continue The temperature rises to 98°C, reacts for 20 minutes, irradiates with ultraviolet light for 5-10 minutes, cools down and discharges;

[0041] Described starch is the mixture of cornstarch, wheatstarch and ricestarch in equal mass ratio; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com