Composting sewage environmental-friendly recycling system

A recycling system and sewage technology, applied in water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as poisoning aquatic organisms, affecting drinking water sources, scenic spots and landscapes, etc. Achieve the effect of increasing sewage purification capacity, improving structural synergy, and reducing plant shutdowns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

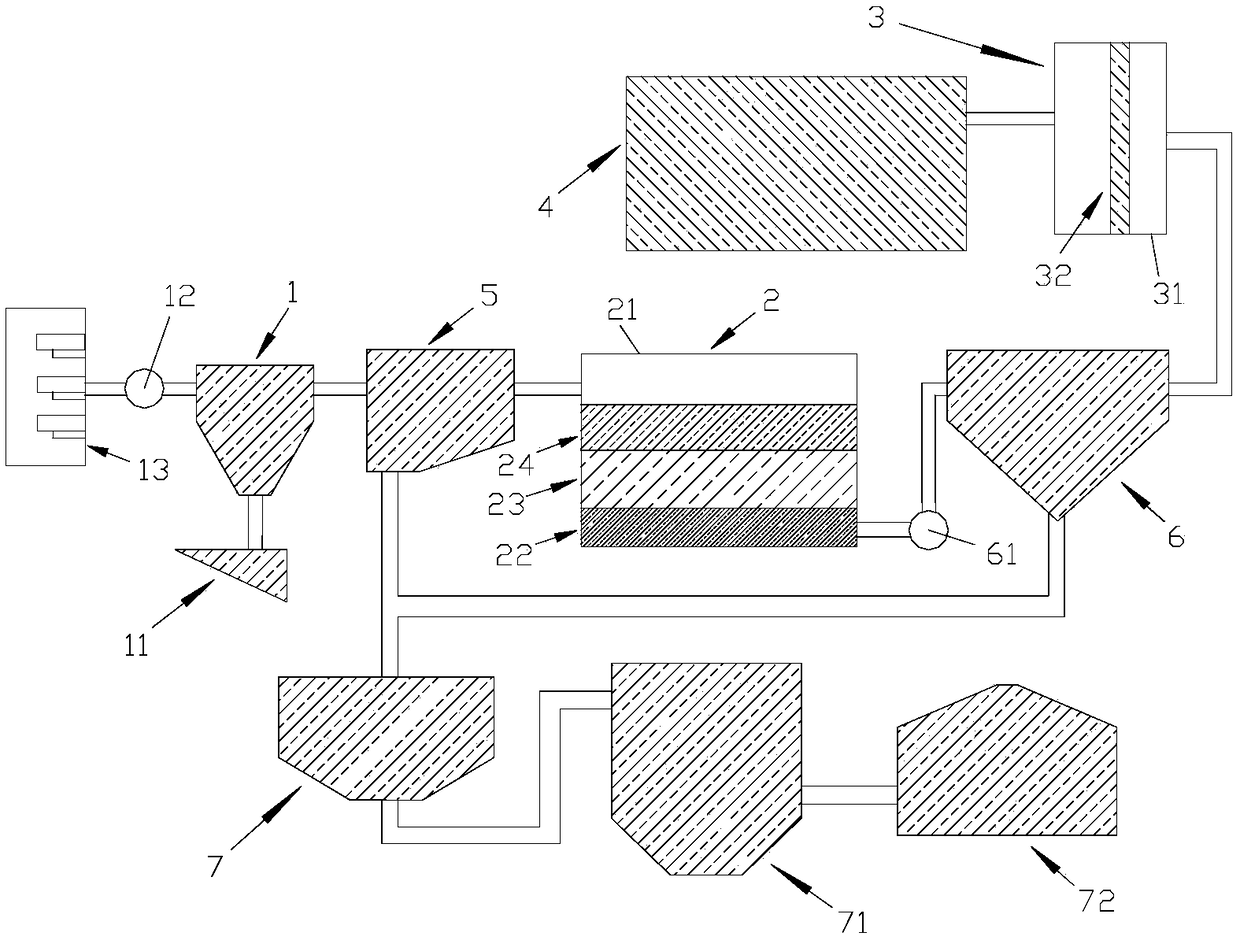

[0017] refer to figure 1 As shown, an environmental protection recovery system for composting sewage, including an aeration grit chamber 1, an artificial infiltration pond 2 arranged on one side of the aeration grit chamber 1, and a filter membrane pond 3 arranged on one side of the artificial infiltration pond 2 The bottom of the aeration grit chamber 1 is connected with a sand washing room 11, and one side of the aeration grit chamber 1 is connected with a water pump 12, and the water pump 12 is connected with a grid room 13; the artificial infiltration tank 2 includes the artificial infiltration tank body 21, and the activated carbon layer 22 arranged inside the artificial infiltration tank body 21, and the marble sand layer 23 arranged inside the artificial infiltration tank body 21 and above the activated carbon layer 22, and arranged on the artificial infiltration tank body 21. The inside of the pool body 21 and the river impact sand layer 24 above the marble sand layer ...

Embodiment 2

[0028] refer to figure 1 As shown, an environmental protection recovery system for composting sewage, including an aeration grit chamber 1, an artificial infiltration pond 2 arranged on one side of the aeration grit chamber 1, and a filter membrane pond 3 arranged on one side of the artificial infiltration pond 2 The bottom of the aeration grit chamber 1 is connected with a sand washing room 11, and one side of the aeration grit chamber 1 is connected with a water pump 12, and the water pump 12 is connected with a grid room 13; the artificial infiltration tank 2 includes the artificial infiltration tank body 21, and the activated carbon layer 22 arranged inside the artificial infiltration tank body 21, and the marble sand layer 23 arranged inside the artificial infiltration tank body 21 and above the activated carbon layer 22, and arranged on the artificial infiltration tank body 21. The inside of the pool body 21 and the river impact sand layer 24 above the marble sand layer ...

Embodiment 3

[0039] refer to figure 1 As shown, an environmental protection recovery system for composting sewage, including an aeration grit chamber 1, an artificial infiltration pond 2 arranged on one side of the aeration grit chamber 1, and a filter membrane pond 3 arranged on one side of the artificial infiltration pond 2 The bottom of the aeration grit chamber 1 is connected with a sand washing room 11, and one side of the aeration grit chamber 1 is connected with a water pump 12, and the water pump 12 is connected with a grid room 13; the artificial infiltration tank 2 includes the artificial infiltration tank body 21, and the activated carbon layer 22 arranged inside the artificial infiltration tank body 21, and the marble sand layer 23 arranged inside the artificial infiltration tank body 21 and above the activated carbon layer 22, and arranged on the artificial infiltration tank body 21. The inside of the pool body 21 and the river impact sand layer 24 above the marble sand layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com