Thermosetting resin compound

A resin composition and thermosetting technology, which is applied in the field of thermosetting resin composition and its composite material, can solve the problems of poor line glue filling effect and poor fluidity, and achieve the effects of not being easy to cut, improving the processability of the substrate, and increasing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

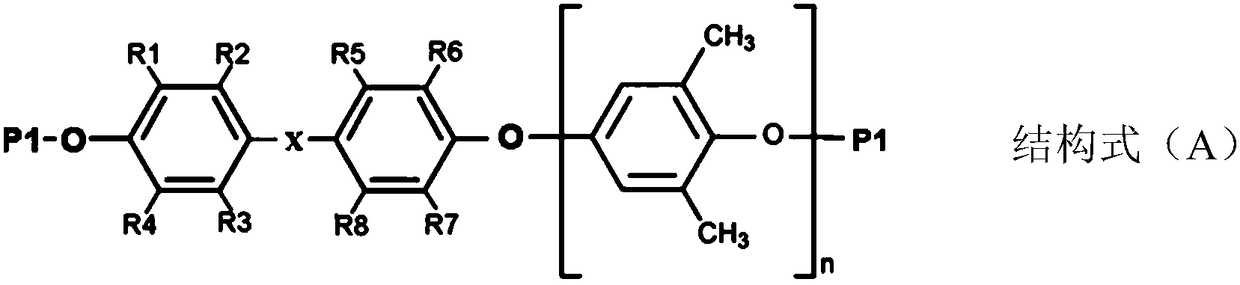

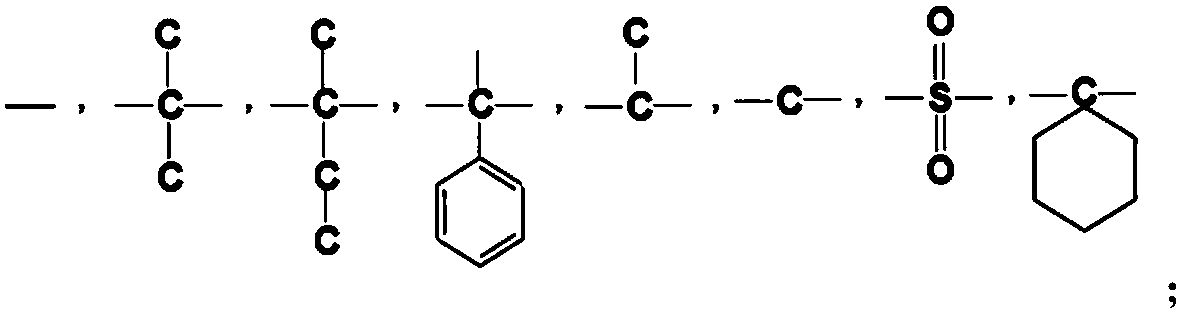

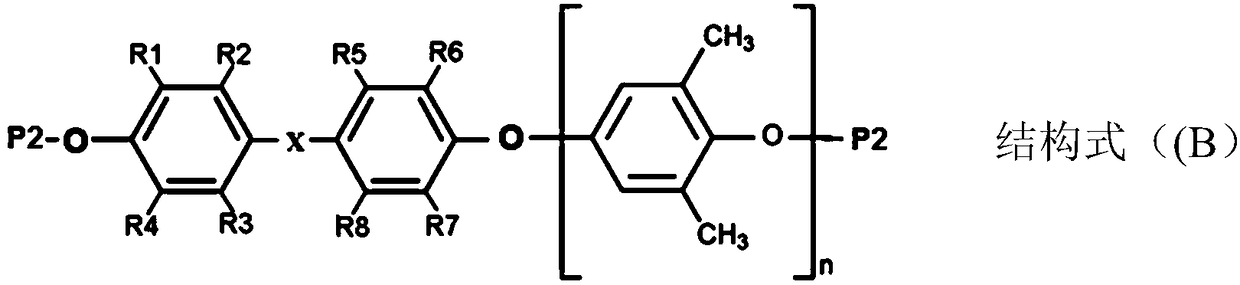

Method used

Image

Examples

Embodiment 1~11

[0109] [Examples 1-11, Comparative Examples 1-3]

[0110] The resin composition shown in Table 1 was mixed with toluene to form the varnish (Varnish) of the thermosetting resin composition, and the above-mentioned varnish was impregnated with Nanya glass fiber cloth (Nanya Plastic Company, cloth type 7628) at room temperature, and then heated at 110 ℃ (impregnation machine) after drying for a few minutes, a prepreg with a resin content of 43wt% was obtained. Finally, four prepregs were stacked layer by layer between two 35μm thick copper foils, at 25kg / cm 2 At a pressure and temperature of 85°C, keep the constant temperature for 20 minutes, then heat up to 185°C at a heating rate of 3°C / min, then keep the constant temperature for 120 minutes, and then slowly cool to 130°C to obtain 0.8mm thick copper foil substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com