Non-formaldehyde albumin adhesive and preparation method thereof

An adhesive and protein glue technology, which is used in the preparation of protein adhesives, animal glue or gelatin, and adhesives, etc., can solve the problem of formaldehyde release from gluing wood-based panels, inability to use wood-based panels for outdoor use, and poor water resistance. and other problems, to achieve the effect of uniform adhesive system, good stability and good water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Above-mentioned curing agent is hydroxyethyl melamine; The preparation method of described curing agent comprises the following steps:

[0048]Put 160kg of 30% glyoxal solution into the reaction kettle, adjust the pH value to 9.0, heat to 60°C, add 55kg of melamine into the reaction solution, raise the temperature to 80°C, keep it warm for 30 minutes, adjust the pH value to 6.0, and react 10 minutes, adjust the pH value to 10.0 and react for 30 minutes, low temperature distillation to 50% solid content, cool down and discharge.

[0049] The above-mentioned dispersion medium water is selected from ordinary tap water or demineralized water.

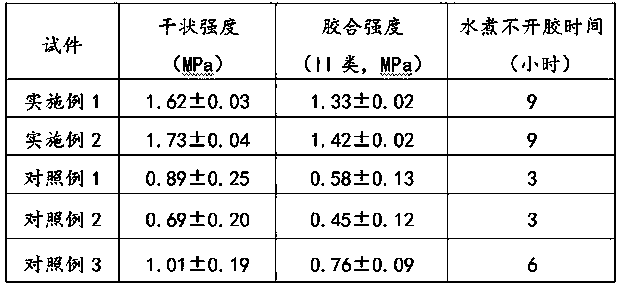

[0050] The adhesive prepared by the preparation method of the present invention, the aldehyde-free protein adhesive has small molecular weight, high activity, good solubility, self-reinforcement, high water-resistant bonding performance, and high stability, and the prepared board can meet the requirements of wood-based panels. The w...

Embodiment 1

[0053] An aldehyde-free protein adhesive consisting of the following materials by weight:

[0054] Demineralized water 72 kg;

[0056] Bromelain 0.1 kg;

[0057] Activator 0.5 kg;

[0058] Ethylene glycol diglycidyl ether 0.3 kg;

[0059] Curing agent 0.9 kg.

[0060] When using the formaldehyde-free protein adhesive in this example: Stir the prepared feather protein adhesive prepolymer and curing agent at room temperature for 10 minutes, and stir well before use.

Embodiment 2

[0062] An aldehyde-free protein adhesive consisting of the following materials by weight:

[0063] Demineralized water 72 kg;

[0065] Bromelain 0.3 kg;

[0066] Activator 1 kg;

[0067] Ethylene glycol diglycidyl ether 0.5 kg;

[0068] Curing agent 1.2 kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com