Heavy oil viscosity reducer as well as preparation method and application thereof

A heavy oil viscosity reducer and heavy oil technology, applied in chemical instruments and methods, earth drilling, production fluids, etc., can solve the problem of low viscosity reduction rate, achieve low oil-water interfacial tension, good solubility, and wide application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides a preparation method for the heavy oil viscosity reducer described in the above technical solution, comprising the following steps:

[0030] Lauryl dimethyl benzyl ammonium chloride, isopropanol, nonylphenol polyoxyethylene ether, ethylene glycol monobutyl ether, disodium edetate, polyoxyethylene octylphenol ether and Mix with water to get thick oil viscosity reducer.

[0031] In the present invention, the order of mixing is preferably: dissolving disodium edetate and polyoxyethylene octylphenol ether in water first, then adding isopropanol, nonylphenol polyoxyethylene ether, ethyl alcohol Glycol Monobutyl Ether, Lauryl Dimethyl Benzyl Ammonium Chloride.

[0032] The present invention has no special limitation on the mixing method, and conventional mixing methods in the field can be used, such as stirring specifically. The present invention has no special limitation on the time and rate of the stirring, as long as the complete disso...

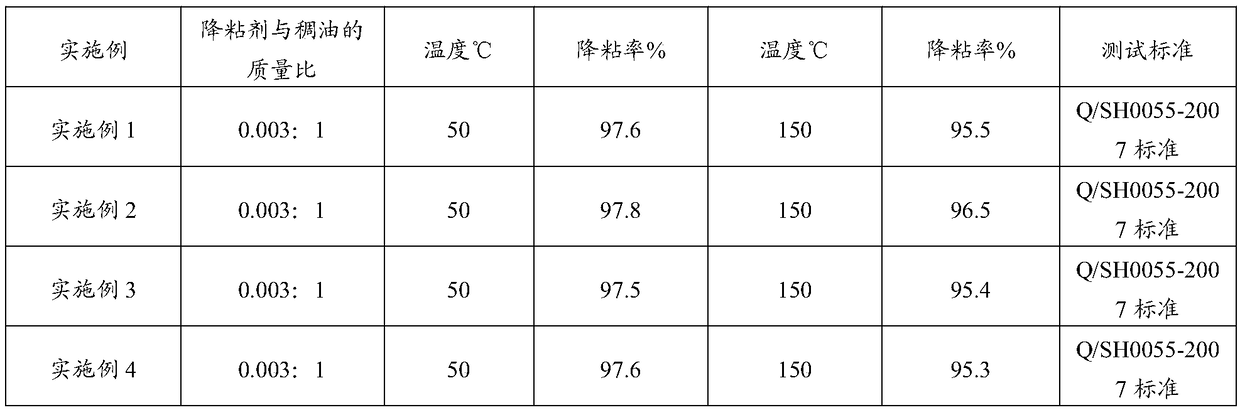

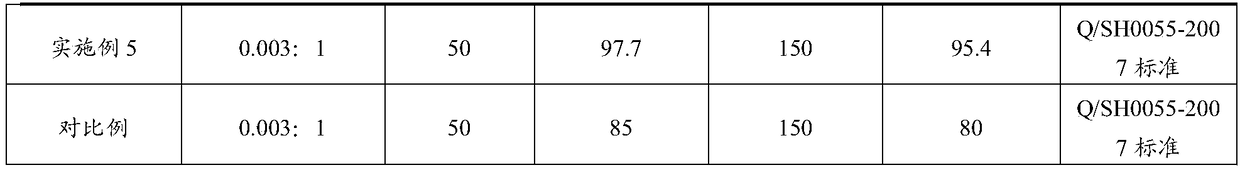

Embodiment 1

[0045] A thick oil viscosity reducer is composed by weight percentage: 2.5% of dodecyl dimethyl benzyl ammonium chloride, 3.4% of isopropanol, 6.7% of nonylphenol polyoxyethylene ether, ethylene glycol monobutyl ether 2.32%, disodium edetate 3%, polyoxyethylene octyl phenol ether 4%, and the balance of water.

[0046] Dissolve disodium edetate and polyoxyethylene octyl phenol ether in water first, then add isopropanol, nonylphenol polyoxyethylene ether, ethylene glycol monobutyl ether, dodecyl dimethyl Benzyl benzyl ammonium chloride, and stir evenly to obtain thick oil viscosity reducer.

[0047] See Table 1 for the evaluation results of the viscosity reduction test of the prepared heavy oil viscosity reducer under the condition of heavy oil viscosity of 1200mPa·S; see Table 2-Table 5 for the evaluation results of viscosity reduction test of the heavy oil viscosity of 50000mPa·S.

Embodiment 2

[0049]A thick oil viscosity reducer is composed by weight percentage: 6.5% of dodecyl dimethyl benzyl ammonium chloride, 2.4% of isopropanol, 0.315% of nonylphenol polyoxyethylene ether, ethylene glycol monobutyl ether 5.81%, disodium edetate 1%, polyoxyethylene octylphenol ether 7%, and the balance of water.

[0050] Dissolve disodium edetate and polyoxyethylene octyl phenol ether in water first, then add isopropanol, nonylphenol polyoxyethylene ether, ethylene glycol monobutyl ether, dodecyl dimethyl Benzyl benzyl ammonium chloride, and stir evenly to obtain thick oil viscosity reducer.

[0051] See Table 1 for the evaluation results of the viscosity reduction test of the prepared heavy oil viscosity reducer under the condition of heavy oil viscosity of 1200mPa·S; see Table 2-Table 5 for the evaluation results of viscosity reduction test of the heavy oil viscosity of 50000mPa·S.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com