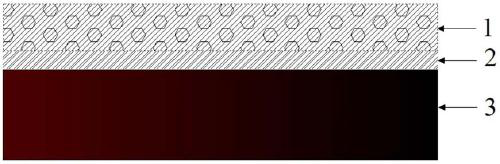

Iron-based composite structure high-temperature anti-corrosion and anti-skid coating and preparation method thereof

A composite structure, anti-skid coating technology, applied in the direction of coating, metal material coating process, etc., can solve the problems of unstable coating friction coefficient, poor thermal shock resistance, insufficient wear resistance, etc., and achieve excellent high temperature resistance. Erosion performance, good anti-skid and wear-resistant performance, low pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the laser cladding iron-based high-temperature corrosion-resistant anti-skid coating comprises the following steps:

[0035] (1) Select Q235 carbon steel with a thickness of 3mm as the substrate (substrate 1), perform sandblasting and degreasing treatment on its surface, then use acetone and absolute ethanol to perform ultrasonic cleaning, clean and dry it with a sample bag Well packaged to avoid surface oxidation;

[0036](2) According to the mass fractions: 31wt% iron, 28wt% chromium, 12wt% boron, 11wt% cobalt, 10wt% nickel, and 8wt% silicon are used to configure the alloy powder, and the proportion of the configured alloy powder to the total mass is 40% alumina powder is mixed and then ball-milled to a particle size of 200-300 mesh to obtain spray powder.

[0037] (3) Bake the SAM2X5 alloy powder without organic binder and the composite powder configured in step (2) in a vacuum oven at 90°C for 30 minutes;

[0038] (4) Laser cladding is ca...

Embodiment 2

[0040] Embodiment 2 (comparative example 1, compared with embodiment 1, does not contain corrosion-resistant bottom layer)

[0041] The preparation method of the laser cladding iron-based high-temperature corrosion-resistant anti-skid coating comprises the following steps:

[0042] (1) Choose Q235 carbon steel with a thickness of 3mm as the substrate, sandblast and degrease the surface, and then clean it with acetone and absolute ethanol ultrasonically. After cleaning and drying, seal it with a sample bag to avoid surface oxidation;

[0043] (2) According to the mass fractions: 31wt% iron, 28wt% chromium, 12wt% boron, 11wt% cobalt, 10wt% nickel, and 8wt% silicon are used to configure the alloy powder, and the proportion of the configured alloy powder to the total mass is 40% alumina powder is mixed and then ball-milled to a particle size of 200-300 mesh to obtain spray powder.

[0044] (3) Bake the prepared composite powder in a vacuum oven at 90°C for 30 minutes;

[0045] ...

Embodiment 3

[0046] Embodiment 3 (comparative example 2, compared with embodiment 1, surface layer does not contain ceramic powder)

[0047] The preparation method of the laser cladding iron-based high-temperature anti-skid coating comprises the following steps:

[0048] (1) Choose Q235 carbon steel with a thickness of 3mm as the substrate, sandblast and degrease the surface, and then clean it with acetone and absolute ethanol ultrasonically. After cleaning and drying, seal it with a sample bag to avoid surface oxidation;

[0049] (2) According to the mass fractions: 31wt% iron, 28wt% chromium, 12wt% boron, 11wt% cobalt, 10wt% nickel, and 8wt% silicon, the alloy powder is configured, and the configured alloy powder is ball milled to 200-300 mesh Particle size, get spray powder.

[0050] (3) Bake the SAM2X5 alloy powder without organic binder and the alloy powder configured in step (2) in a vacuum oven at 90°C for 30 minutes;

[0051] (4) Laser cladding is carried out by synchronous powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com