Preparation method of c@ ferric oxide composite nanomaterial with porous structure as well as product and application of c@ ferric oxide composite nanomaterial

A technology of composite nanomaterials and porous structures, which is applied in the field of preparation of C@ferric oxide composite nanomaterials, can solve the problems of poor electrical conductivity of semiconductor metal oxides, improve gas sensing performance, increase specific surface area, and improve the preparation process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Take 10g of egg white and deionized water, mix and stir, the concentration of egg white is 30wt%, filter and remove the white floc in the egg white solution, and obtain solution A;

[0020] According to the molar concentration of 0.05mol / L with FeSO 4 ·7H 2 O aqueous solution, after stirring for 30min, add ethylene glycol to the above solution, the volume ratio of ethylene glycol and deionized water is 1:1, stir for 10min, to obtain solution B;

[0021] Mix solution A and solution B, the volume ratio of solution A and solution B is 1~3; after stirring for 30 minutes, heat the solution to 60 °C under stirring, keep the solution for 8 hours, then cool the solution to room temperature, and put the obtained product at -80 ℃ freeze-drying; the dried samples were placed in a tube furnace, and heat-treated in a high-purity nitrogen gas atmosphere. The heat treatment temperature was 300°C for 2 hours, 500°C for 2.5h, and the heating rate was 2°C / min. Grinding to obtain C@Fe ...

Embodiment 2

[0024] Take 10g of egg white and deionized water, mix and stir, the concentration of egg white is 20wt%, filter and remove the white floc in the egg white solution to obtain solution A;

[0025] According to the molar concentration of 0.1mol / L with FeSO 4 ·7H 2 O aqueous solution, after stirring for 30min, add ethylene glycol to the above solution, the volume ratio of ethylene glycol and deionized water is 1:3, stir for 10min, to obtain solution B;

[0026] Mix solution A and solution B, the volume ratio of solution A and solution B is 1~2; after stirring for 30 minutes, heat the solution to 50 °C under stirring, keep the solution for 8 hours and then lower the solution to room temperature, and put the obtained product at -80 ℃ freeze-drying; put the dried sample in a tube furnace, and heat-treat it in a high-purity nitrogen gas atmosphere. @Fe 2 o 3 composite nanomaterials.

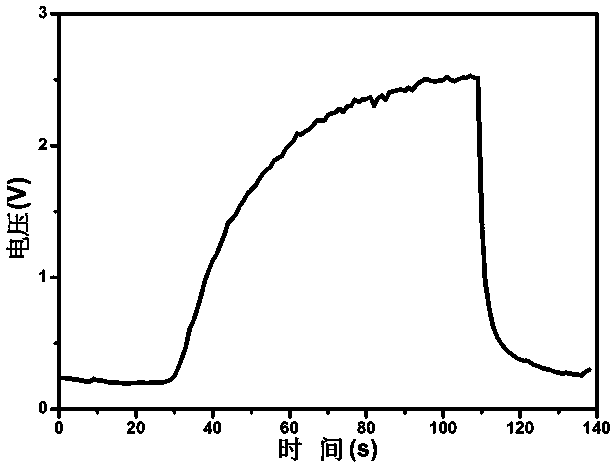

[0027] The porous C@Fe synthesized in this example 2 o 3 The sensitivity to 1ppm acetone is 17...

Embodiment 3

[0029] Take 10g of egg white and deionized water, mix and stir, the concentration of egg white is 10wt%, filter and remove the white floc in the egg white solution, and obtain solution A;

[0030] According to the molar concentration of 0.2mol / L with FeSO 4 ·7H 2 O aqueous solution, after stirring for 30min, add ethylene glycol to the above solution, the volume ratio of ethylene glycol and deionized water is 1:2, stir for 10min, to obtain solution B;

[0031] Mix solution A and solution B, the volume ratio of solution A and solution B is 1~2; after stirring for 30 minutes, heat the solution to 50 °C under stirring, keep the solution for 8 hours and then lower the solution to room temperature, and put the obtained product at -80 ℃ freeze-drying; put the dried sample in a tube furnace, and heat-treat it in a high-purity nitrogen gas atmosphere. @Fe 2 o 3 composite nanomaterials.

[0032] The porous C@Fe synthesized in this example 2 o 3 The sensitivity to 1ppm acetone is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com