Ultraviolet-proof fabric

A technology of anti-ultraviolet and fabrics, applied in the field of fabrics, can solve the problems of poor anti-ultraviolet performance, human skin damage, poor air permeability, etc., and achieve the effect of good antistatic property, wide application and low transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

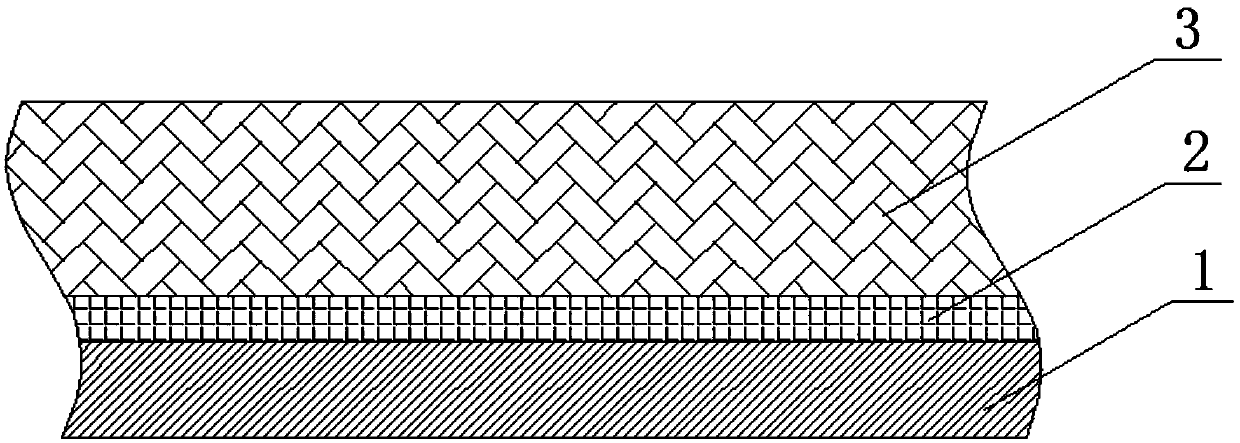

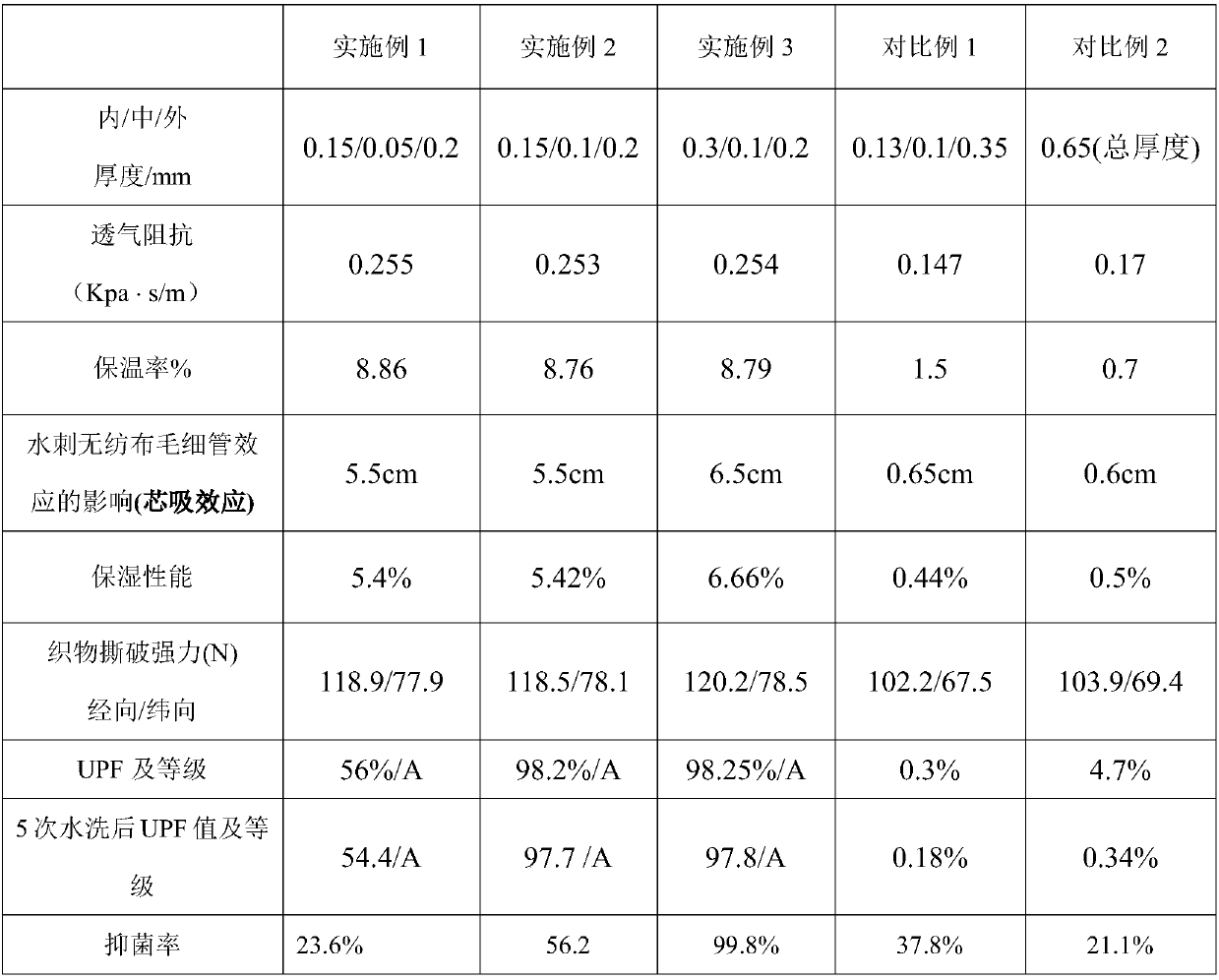

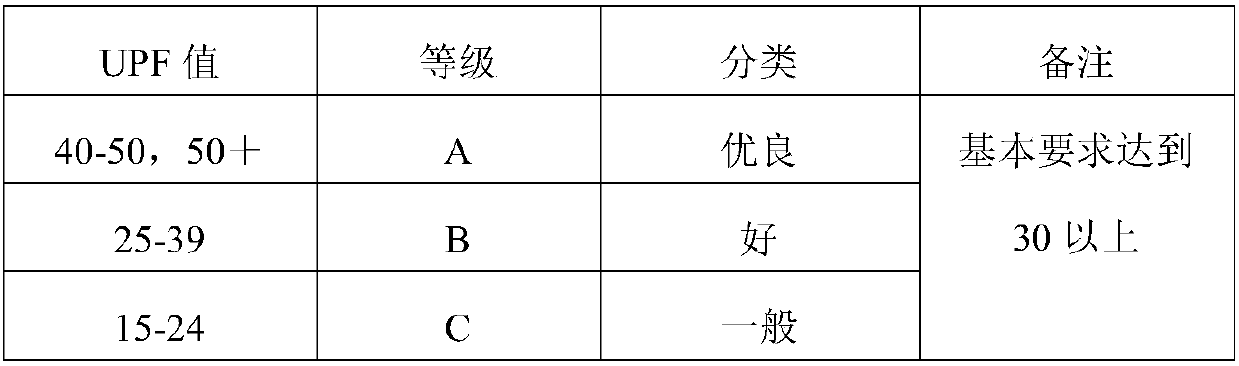

[0020] An anti-ultraviolet fabric, the fabric is sequentially composed of a moisturizing inner layer 1, an anti-ultraviolet middle layer 2 and a breathable outer layer 3 from the inside to the outside. bonded together; the moisturizing inner layer 1 is a spunlace non-woven fabric made of mulberry silk, wherein the fineness of the mulberry silk is 1.2tex, and the length is 45mm. The anti-ultraviolet middle layer 2 is a polytetrafluoroethylene microporous film with a graphene coating on the outer layer; the air-permeable outer layer 3 is a double-sided bird's-eye structure, which is woven by anti-ultraviolet yarn, and the ribbed needle arrangement, The dial needles are sorted in ABAB order, and the cylinder needles are sorted in AABC order. The anti-ultraviolet yarn is a composite yarn made of polylactic acid filament (150D), polyester filament (136D) and flax fiber filament (3.6D) It is made by twisting and plying.

[0021] The thickness of the moisturizing inner layer 1 is 0....

Embodiment 2

[0025] The difference between embodiment 2 and embodiment 1 is that the thickness of the anti-ultraviolet intermediate layer 2 is 0.1 mm, and the outer surface of the graphene coating on the anti-ultraviolet intermediate layer 2 is coated with a nano-titanium dioxide coating. Wherein, the particle size of titanium dioxide is 5nm, and the concentration of the coating solution is 4%.

[0026] The surface of the graphene coating has a concave-convex sheet structure, and the nano-titanium dioxide coating has a good adhesion effect. Moreover, the nano-titanium dioxide coating has good self-cleaning performance and ultraviolet shielding performance.

Embodiment 3

[0028] On the basis of Example 2, a layer of bamboo fiber antibacterial layer is arranged between the moisturizing inner layer 1 and the ultraviolet-proof middle layer 2, and the bamboo fiber is used as warp and weft yarns and is woven with a plain weave structure.

[0029] The antibacterial layer of bamboo fiber can greatly improve the antibacterial performance of the fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com