Preparation method for compounding three-dimensional graphene under assistance of L-cysteine

A cysteine and graphene technology, applied in graphene, chemical instruments and methods, carbon compounds, etc., can solve problems such as complex preparation process, achieve simple preparation process, improve electrochemical performance, and non-toxic and harmless raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method for L-cysteine assisted synthesis of three-dimensional graphene, comprising the following steps:

[0026] 1) Disperse GO powder in ultrapure water and sonicate for 2h, and the sonication power is 70W to obtain 2mg / mL GO aqueous solution.

[0027] 2) Weigh L-cysteine and add it to the GO aqueous solution in step 1), wherein the mass ratio of GO and L-cysteine is 1:(5-20), and stir for 10 minutes.

[0028] 3) The mixed solution in step 2) was placed in an oil bath at 80° C. for 9 h, and then washed with deionized water and absolute ethanol for 4 to 6 times to obtain GO hydrogel.

[0029] 4) The GO hydrogel in step 3) was freeze-dried at -40°C for 48 hours to obtain GO aerogel.

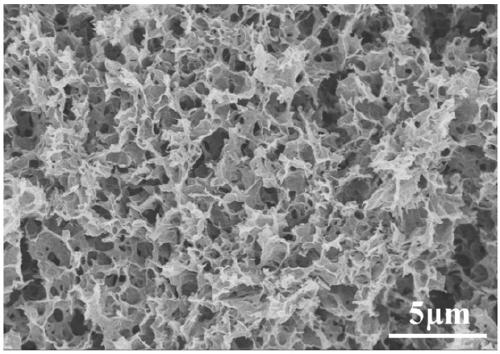

[0030] 5) Calcining the GO airgel in step 4) at 750° C. for 2 h in an Ar atmosphere to obtain a three-dimensional rGO airgel.

Embodiment 1

[0033] 1) Disperse GO powder in ultrapure water and sonicate for 2 h to obtain 2 mg / mL GO aqueous solution.

[0034] 2) Weigh L-cysteine and add it to the GO aqueous solution in step 1), wherein the mass ratio of GO and L-cysteine is 1:5, and stir for 10 min.

[0035] 3) The mixed solution in step 2) was placed in an oil bath at 80° C. for 9 h, and then washed 4 times with deionized water and absolute ethanol to obtain GO hydrogel.

[0036] 4) The GO hydrogel in step 3) was freeze-dried for 48 hours to obtain GO aerogel.

[0037] 5) Calcining the GO airgel in step 4) at 750° C. for 2 h in an Ar atmosphere to obtain a three-dimensional rGO airgel.

Embodiment 2

[0039] 1) Disperse GO powder in ultrapure water and sonicate for 2 h to obtain 2 mg / mL GO aqueous solution.

[0040] 2) Weigh L-cysteine and add it to the GO aqueous solution in step 1), wherein the mass ratio of GO and L-cysteine is 1:15, and stir for 10 min.

[0041] 3) The mixed solution in step 2) was placed in an oil bath at 80° C. for 9 h, and then washed five times with deionized water and absolute ethanol to obtain GO hydrogel.

[0042] 4) The GO hydrogel in step 3) was freeze-dried for 48 hours to obtain GO aerogel.

[0043] 5) Calcining the GO airgel in step 4) at 750° C. for 2 h in an Ar atmosphere to obtain a three-dimensional rGO airgel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com