Composite board for power distribution cabinet

A technology for composite panels and power distribution cabinets, which is applied to electrical equipment shells/cabinets/drawers, electrical components, chassis/boxes/drawer parts, etc., which can solve the problem of high cost, uneven conduction, and inability to form conductive channels and other problems to achieve the effect of avoiding multiple processes, avoiding accumulation of static electricity, and uniform contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

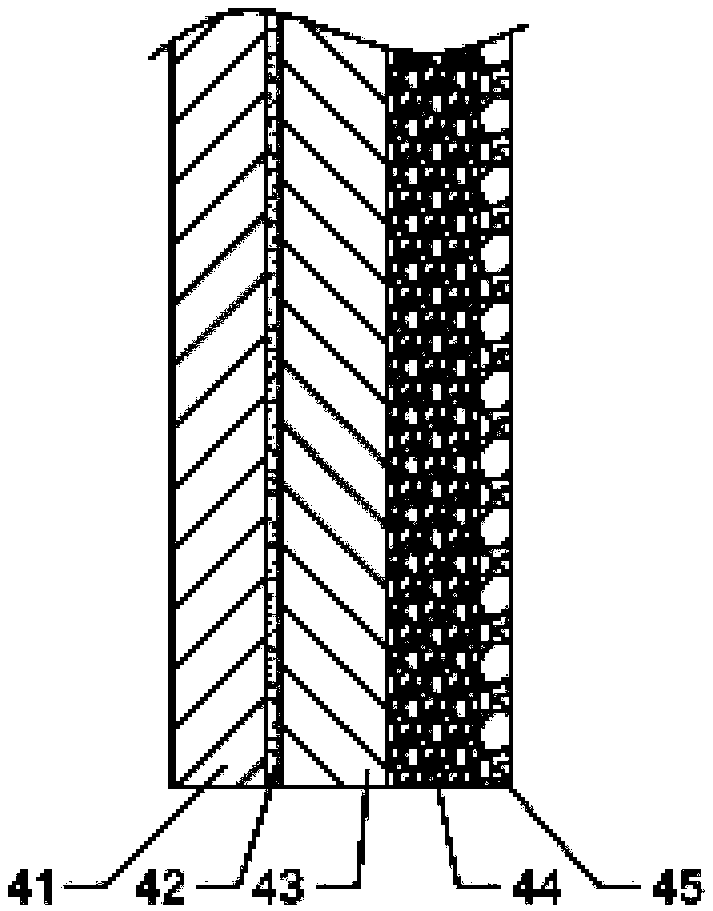

[0023] Embodiment 1: Step 1: Weigh 30 parts of phenolic resin powder, 10 parts of graphite, 5 parts of polyacrylic acid, 7 parts of glass fiber, and 3 parts of urotropine by weight, mix the above raw materials evenly, and place in a vacuum environment Extrude, then heat to 240~245°C, and press for 1.5 hours to obtain a transition layer plate; Step 2: Weigh 10 parts by weight of phenol, 15 parts of formaldehyde, stir well, then slowly add 4 parts of ammonia water, at 60°C Reduce the pressure and condense for 1 hour to obtain a translucent mixed colloid; continue to condense for another 1 hour to obtain a transparent colloid; Step 3: Put the transition layer plate into the plate mold, the area of the mold is slightly larger than the area of the transition layer plate, and the depth of the mold is higher than that of the transition layer Plate thickness, take 5~10 parts of aluminum-doped zinc oxide powder and evenly cover the transition layer plate, take copper wire, place one...

Embodiment 2

[0024] The difference between the second embodiment and the first embodiment is that the silica gel particles with a diameter of 0.5-1 mm are removed from the raw materials in step 5, and finally the finished product C is obtained.

[0025] Refer to the "Test Method for Volume Resistivity and Surface Resistivity of Solid Insulating Materials (GB 1410-89)", the surface resistivity of the transition layer side of the initial product A falls below 10 5 ~10 6 Within the range of Ω·cm, it conforms to the design of the present invention.

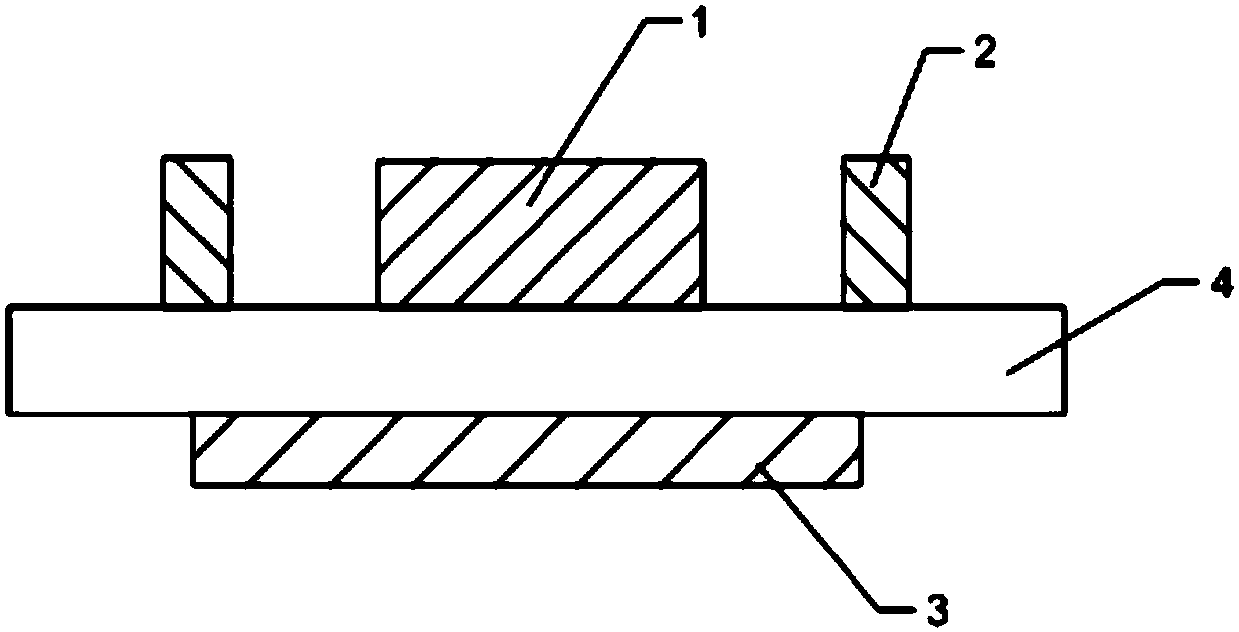

[0026] Refer to the "Testing Method for Volume Resistivity and Surface Resistivity of Solid Insulating Materials (GB 1410-89)", wherein sample 4 is a square plate, and electrodes 1, 2, and 3 are all set on the cross-section of sample 4. The actual The measured data is the parallel resistance between the materials of each layer, but since the resistance of other layers except the conductive layer is very large, the influence on the test result is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com