Fish flesh fragrance-locking, taste-controlling, and flavor-improving method

A technology for fish meat and aroma locking, which is applied to food ingredients as taste modifiers, food ingredients as taste modifiers, and preservation of meat/fish with a coating protective layer, etc. It can improve the anti-freezing denaturation ability, good aroma locking effect and fast absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

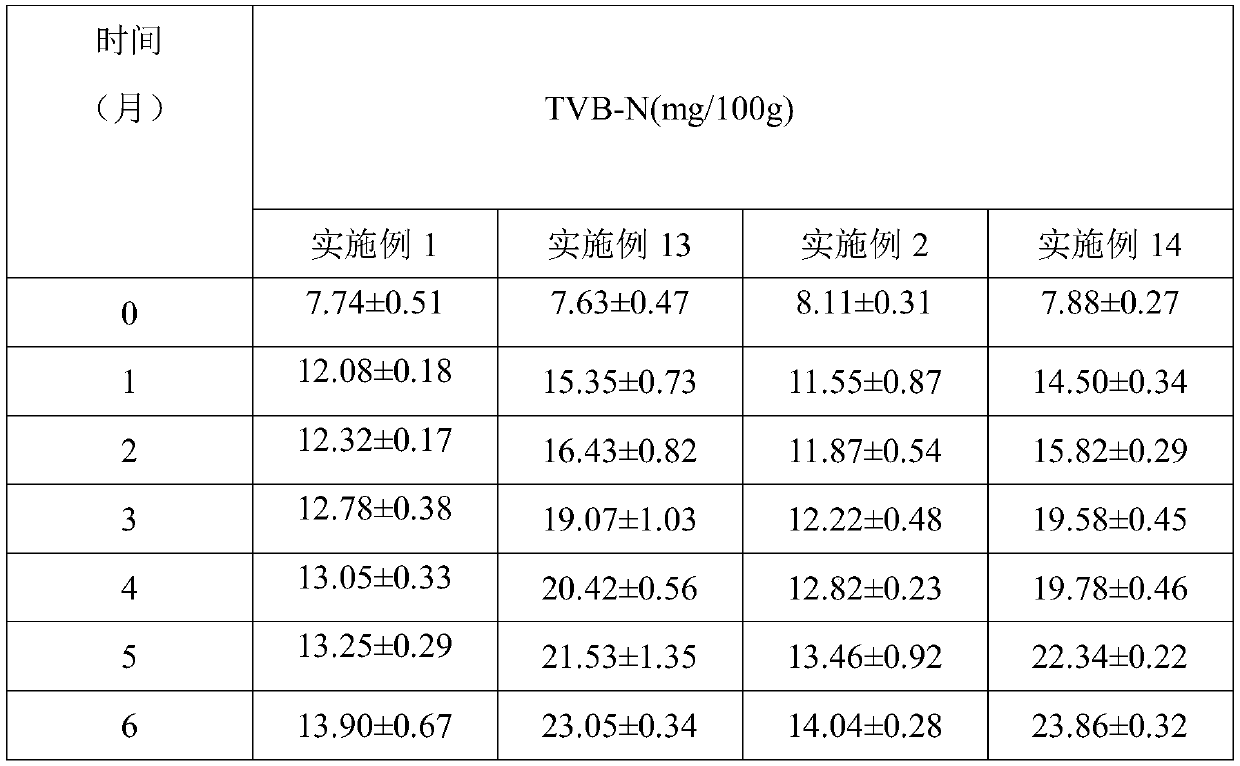

[0043] Example 1: Fragrance and taste control and flavor improvement of frozen silver carp fillets

[0044] 1) Silver carp pretreatment: Remove scales, viscera and gills from fresh or thawed silver carp, cut them into fillets with a thickness of 3-4mm, wash and drain for later use.

[0045]2) Pulse breathing tumbling of silver carp fillets and coating solid film on the surface of the fish meat: Weigh 1000kg silver carp fillets and add them to the vacuum tumbling machine, add 1000kg of compound deodorizing quality improver solution (contains seaweed sugar 4kg, sodium polyphosphate 5kg, carrageenan 0.4kg, perilla powder 1.3kg, black tea powder 0.5kg, ginger powder 1.7kg), vacuum-tumble and marinate for 0.5 hour, deflate, then add 0.05kg calcium lactate and 0.07 kg potassium chloride in the drum, vacuum-tumbled and marinated for 0.5 hours, deflated, then added 0.05kg calcium lactate and 0.07kg potassium chloride in the drum, vacuum-tumbled and marinated for 0.5 hours, deflated, a...

Embodiment 2

[0047] Example 2: Fragrance and flavor control of frozen silver carp fish segments and its flavor improvement

[0048] 1) Silver carp pretreatment: Remove scales, viscera and gills from fresh or thawed silver carp, cut them into 6-8cm fish segments, wash, drain and set aside.

[0049] 2) Pulse breathing tumbling of silver carp fish segments and coating solid film on the surface of fish meat: Weigh 1000kg silver carp fish segments and put them into a vacuum tumbler, add 2000kg of compound deodorizing quality improver solution (contains seaweed 24kg of sugar, 30kg of sodium polyphosphate, 2.4kg of carrageenan, 1.5kg of perilla powder, 1.6kg of black tea powder, and 1.6kg of ginger powder), vacuum-tumbled and marinated for 0.5 hours, deflated, and then added 0.4kg of calcium lactate and 0.5 kg potassium chloride in the drum, vacuum-tumble and marinate for 0.5 hours, let the air out, then add 0.4kg calcium lactate and 0.5kg potassium chloride in the drum, vacuum-tumble and marinat...

Embodiment 3

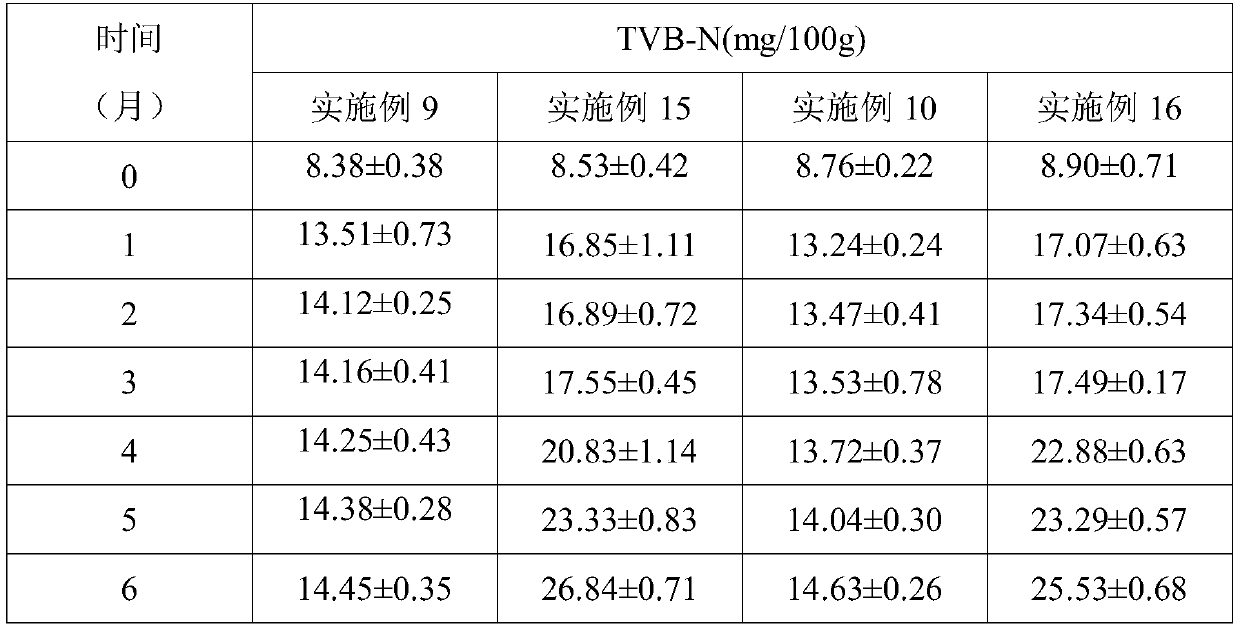

[0051] Example 3: Fragrance and taste control and flavor improvement of frozen bighead carp fillets

[0052] 1) Pretreatment of bighead carp: kill the commercially available bighead carp quickly or after thawing, remove the scales, viscera and gills, cut into fillets with a thickness of 3-4 mm, wash, drain and set aside.

[0053] 2) Pulse breathing tumbling of bighead carp fillets and coating and solid film on the surface of fish meat: Weigh 1000kg bighead carp fillets and put them into a vacuum tumbler, add 1000kg of compound deodorizing quality improver solution (contains trehalose 4.5kg, sodium polyphosphate 5kg, carrageenan 0.4kg, perilla powder 0.5kg, black tea powder 0.8kg, ginger powder 1.0kg), vacuum-tumbled and marinated for 0.5 hour, deflated, then added 0.05kg calcium lactate and 0.07 kg potassium chloride in the drum, vacuum-tumbled and marinated for 0.5 hours, deflated, then added 0.05kg calcium lactate and 0.07kg potassium chloride in the drum, vacuum-tumbled and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com