Low-salt cuttlefish paste with high cuttlefish meat content and preparation method of low-salt cuttlefish paste

A technology of cuttlefish slippery and cuttlefish, applied in the direction of freezing/cooling preservation of meat/fish, food science, etc., to achieve the effect of improving whiteness, increasing mass ratio, and improving gel performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

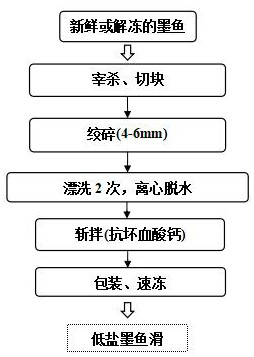

Method used

Image

Examples

Embodiment 1

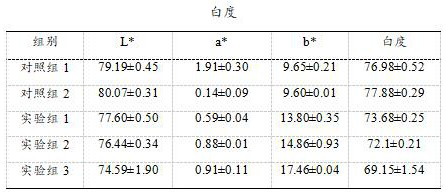

[0031] Remove the head, skin, and viscera of the frozen cuttlefish, wash and cut into pieces; grind the fish pieces, and wring them out through a 4-6 mm sieve plate. The fish meat was rinsed with 0.2% (w / v) sodium bicarbonate, 0.2% (w / v) sodium citrate, 0.1% (w / v) sodium carbonate and 0.2% (w / v) yeast extract Rinse twice with the rinsing liquid, the mass ratio of the fish meat to the rinsing liquid is 1:2.5, stir while rinsing, 10 min each time, and centrifuge and dehydrate at a speed of 3000-3500 r / min for 3-5 min; the fish after rinsing and dehydration is empty Chop until the hand feels no grainy, and the fish paste is smooth; add 1.0% (w / w) salt and 2.0% (w / w) calcium ascorbate to the above fish paste and continue beating for 3-5 minutes; add other auxiliary materials to the slurry, including 1.0% (w / w) TGase, 2.0% (w / w) white sugar, 3.0% (w / w) egg white liquid, 2.0% (w / w) vegetable oil, 2.0% (w / w) potato starch, mixed uniform; the above slurry is poured into a plastic pac...

Embodiment 2

[0033] Remove the head, skin, and viscera of fresh cuttlefish, wash and cut into pieces; grind the fish pieces, and wring them out through a 4-6 mm sieve plate. The fish meat was rinsed with 0.2% (w / v) sodium bicarbonate, 0.2% (w / v) sodium citrate, 0.1% (w / v) sodium carbonate and 0.1% (w / v) yeast extract Rinse twice with the rinsing liquid, the mass ratio of the fish meat to the rinsing liquid is 1:2, stir while rinsing, 10 min each time, and centrifuge and dehydrate at a speed of 3000-3500 r / min for 3-5 min; the fish after rinsing and dehydration is empty Chop until the hand feels no grainy, and the fish paste is smooth; add 1.0% (w / w) salt and 2.5% (w / w) calcium ascorbate to the above fish paste and continue beating for 3-5 minutes; add other auxiliary materials to the paste, including 1.0% (w / w) TGase, 2.0% (w / w) white sugar, 3.0% (w / w) egg white liquid, 2.0% (w / w) vegetable oil, 2.0% (w / w) potato starch, mixed uniform; the above slurry is poured into a plastic packaging b...

Embodiment 3

[0035]Remove the head, skin, and viscera of the frozen cuttlefish, wash and cut into pieces; grind the fish pieces, and wring them out through a 4-6 mm sieve plate. The fish meat was rinsed with 0.2% (w / v) sodium bicarbonate, 0.2% (w / v) sodium citrate, 0.1% (w / v) sodium carbonate and 0.3% (w / v) yeast extract Rinse twice with rinsing solution, the mass ratio of fish meat to rinsing solution is 1:3, stir while rinsing, 10 minutes each time, and centrifuge and dehydrate at a speed of 3000-3500 r / min for 3-5 minutes; the fish after rinsing and dehydration is empty Chop until the hand feels no grainy, and the fish paste is smooth; add 1.0% (w / w) salt and 1.5% (w / w) calcium ascorbate to the above fish paste and continue beating for 3-5 minutes; add other auxiliary materials to the slurry, including 1.0% (w / w) TGase, 2.0% (w / w) white sugar, 3.0% (w / w) egg white liquid, 2.0% (w / w) vegetable oil, 2.0% (w / w) potato starch, mixed uniform; the above slurry is poured into a plastic packag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com