Y type molecular sieve prepared from white clay served as raw material and method thereof

A technology of molecular sieve and lime mud, which is applied in the direction of octahedral crystalline aluminosilicate zeolite and crystalline aluminosilicate zeolite, can solve the problems of environmental pollution and large emissions, and achieve simple preparation process, single crystal phase, and easy industrialization The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] 1) Add 40.0 g of anhydrous sodium carbonate solid to 20.0 g of lime mud, mix evenly, and calcinate at 850°C for 2 hours to obtain alkali fusion clinker;

[0060] 2) After the above-mentioned alkali fusion clinker is cooled to room temperature, add 300ml of deionized water and 40ml of directing agent to mix, so that the whole system has 16.1Na 2 O: Al 2 o 3 :10SiO2 2 :715H 2 The material molar ratio of O, after stirring for 5h, silica-alumina gel is obtained;

[0061] 3) Aging the silica-alumina gel obtained above at a temperature of 20°C for 48h, placing it in a crystallization tank at 85°C for 24h, cooling and filtering to remove the mother liquor, washing with deionized water until neutral Dry at 100°C to obtain Y-type molecular sieve.

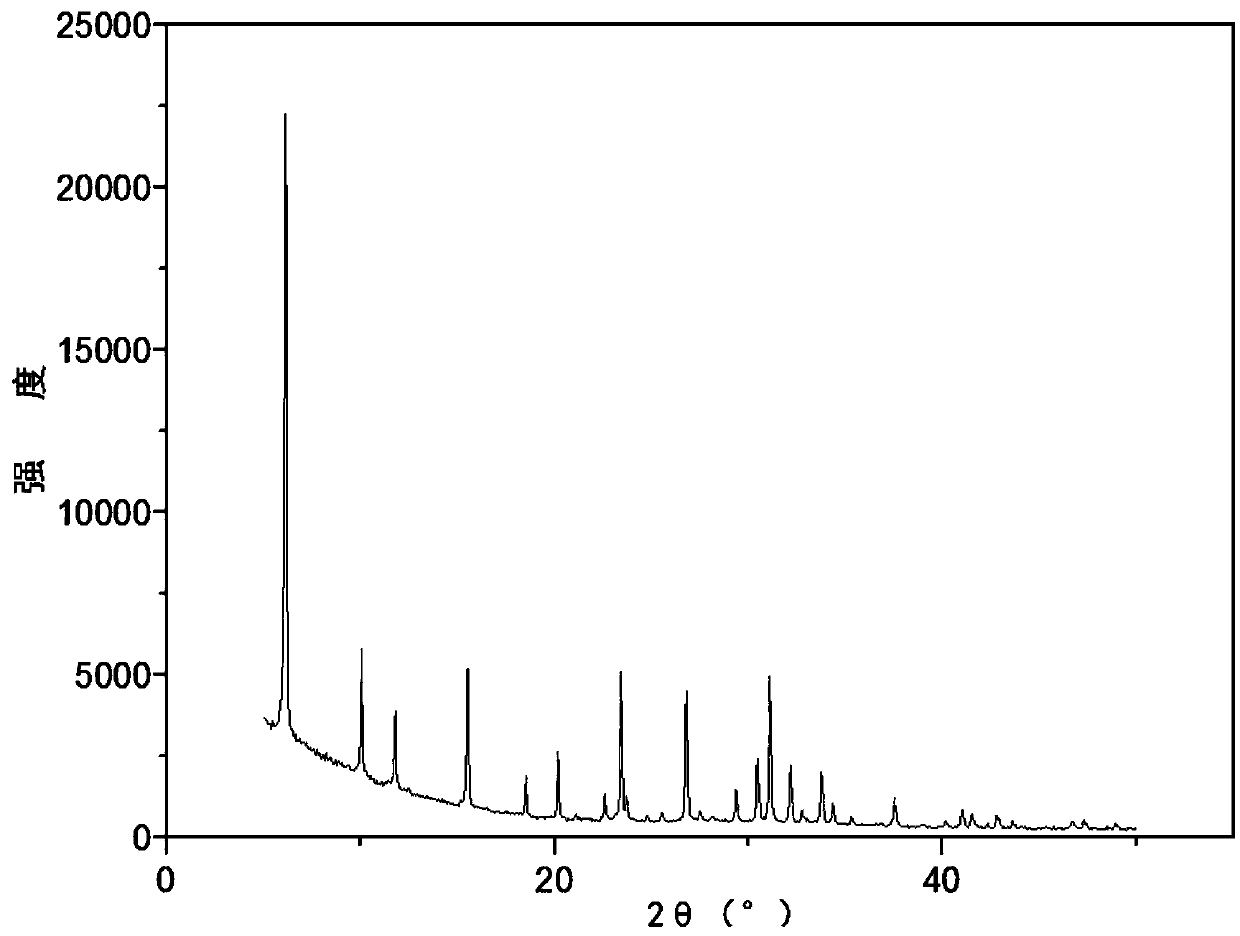

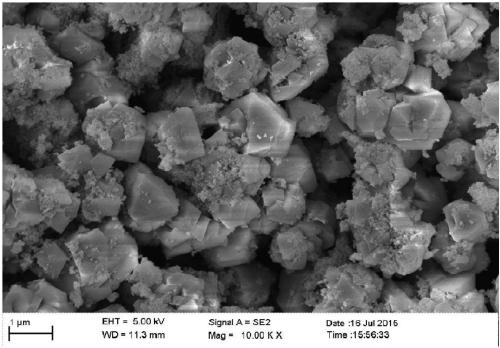

[0062] After testing, the XRD spectrum of the Y-type molecular sieve gained in Example 1 is shown in figure 1 , SEM photo see figure 2 , nitrogen isotherm adsorption-desorption curve see Figure 5 , the pore size distribution...

Embodiment 2

[0064] 1) Add 26.0 g of sodium hydroxide solid to 20.0 g of lime mud, mix well, and calcinate at 650°C for 3 hours to obtain alkali fusion clinker;

[0065] 2) After the above-mentioned alkali fusion clinker is cooled to room temperature, add 320ml of deionized water and 44ml of directing agent to mix, so that the whole system has 13.9Na 2 O: Al 2 o 3 :10SiO2 2 :763H 2 The material molar ratio of O, after stirring for 3h, silica-alumina gel is obtained;

[0066] 3) Aging the silica-alumina gel obtained above at a temperature of 23°C for 30h, placing it in a crystallization kettle at 90°C for 60h, cooling and filtering to remove the mother liquor, washing with deionized water until neutral Dry at 100°C to obtain Y-type molecular sieve.

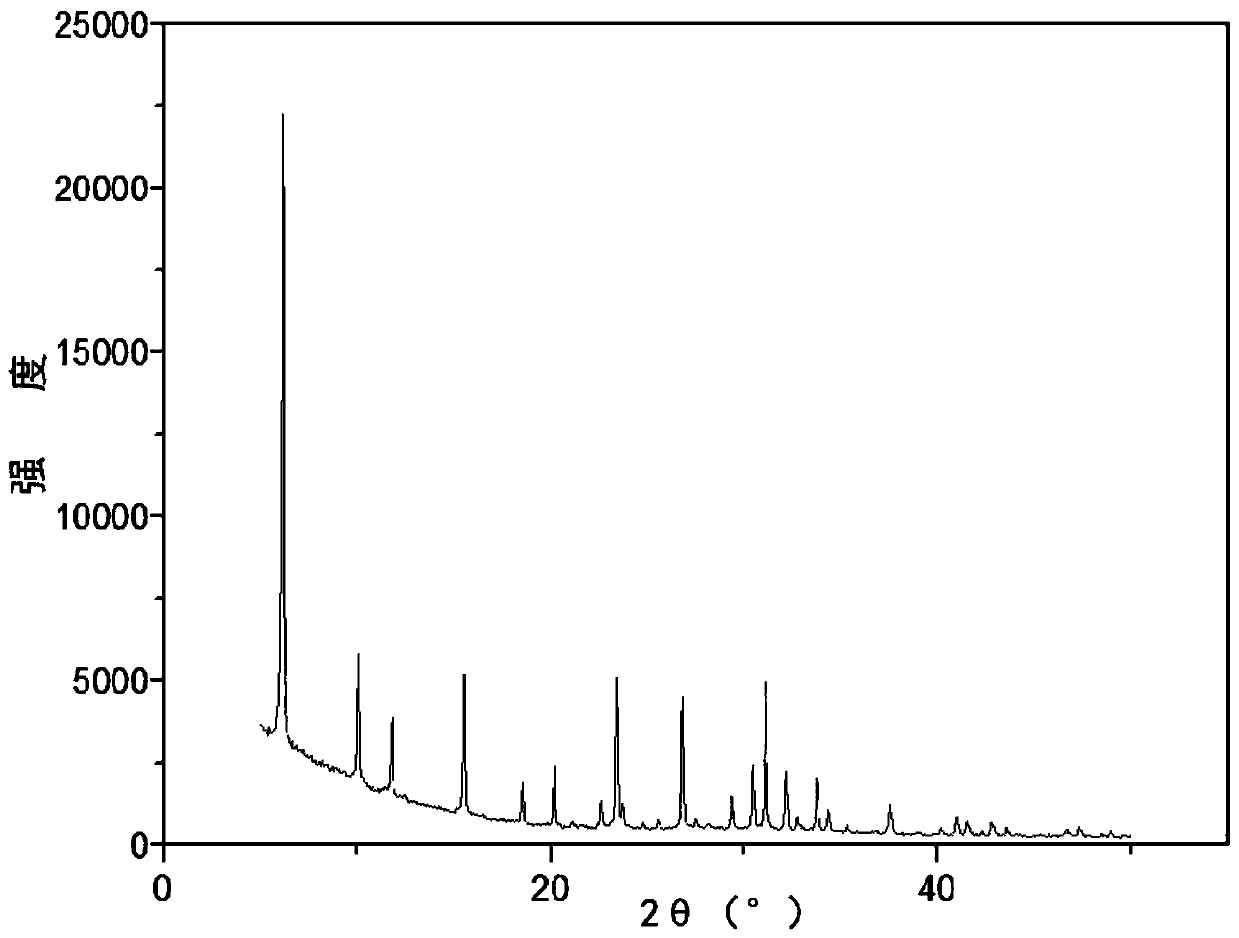

[0067] After testing, the XRD spectrum of the obtained Y-type molecular sieve is shown in image 3 .

Embodiment 3

[0069] 1) Add 30.0 g of sodium hydroxide solid to 20.0 g of lime mud, mix well, and calcinate at 780°C for 2.5 hours to obtain alkali fusion clinker;

[0070] 2) After the above-mentioned alkali fusion clinker is cooled to room temperature, add 360ml of deionized water and 46.8ml of directing agent to mix, so that the whole system has 16.0Na 2 O: Al 2 o 3 :10SiO2 2 :800H 2 The material molar ratio of O, after stirring for 4h, silica-alumina gel is obtained;

[0071] 3) Aging the silica-alumina gel obtained above at a temperature of 25°C for 24h, placing it in a crystallization tank at 110°C for 24h, cooling and filtering to remove the mother liquor, washing with deionized water until neutral Dry at 100°C to obtain Y-type molecular sieve.

[0072] After testing, the XRD spectrum of the obtained Y-type molecular sieve is shown in Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com