Antibacterial biodegradable water absorbing material used for refrigerated foods and preparation method thereof

A technology for biodegradable and water-absorbing materials, applied in the field of bacteriostatic biodegradable water-absorbing materials and their preparation, can solve problems such as poor biodegradability, hidden dangers, ecological environment threats, etc., and achieve high content of tea polyphenols and high antibacterial properties. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of antibacterial biodegradable water-absorbing material used for refrigerated food is obtained according to the following steps:

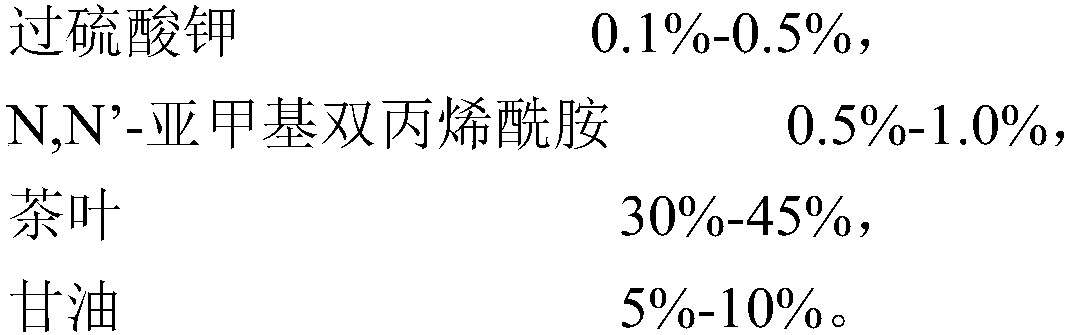

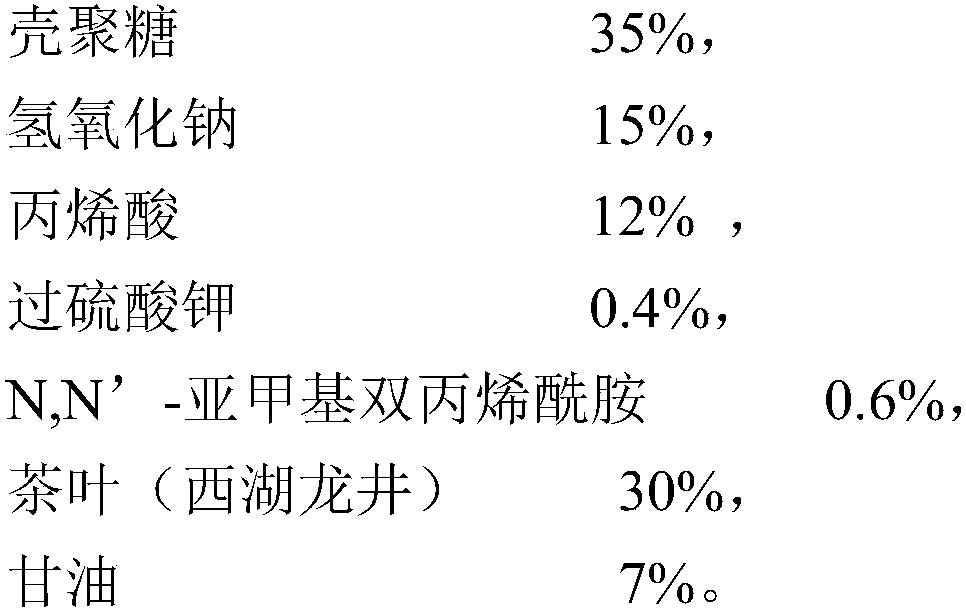

[0036] (1) Take raw materials by mass percentage:

[0037]

[0038] (2) Preparation of freeze-dried tea powder

[0039] Wash the fresh West Lake Longjing and dry it naturally, crush and grind the fresh tea leaves, vacuum freeze-dry the ground tea leaves at -40°C and 5Pa for 22 hours, and then crush the freeze-dried tea leaves , crushed into powder below 20 mesh for later use,

[0040] (3) Preparation of chitosan water-absorbent resin

[0041] Dissolve sodium hydroxide in deionized water, slowly add acrylic acid, stir constantly to make the reaction complete, and cool the obtained neutralizing solution for later use; then dissolve chitosan in deionized water, pour it into the neutralizing solution after fully stirring, and then Add initiator potassium persulfate and cross-linking agent N,N'-methylenebisacrylamide, and stir contin...

Embodiment 2

[0045] A kind of antibacterial biodegradable water-absorbing material used for refrigerated food is obtained according to the following steps:

[0046] (1) Take raw materials by mass percentage:

[0047]

[0048] (2) Preparation of freeze-dried tea powder

[0049] Wash the fresh West Lake Longjing and dry it naturally, crush and grind the fresh tea leaves, vacuum freeze-dry the ground tea leaves at -50°C and 10Pa for 24 hours, and then crush the freeze-dried tea leaves , crushed into powder below 20 mesh for later use,

[0050] (3) Preparation of chitosan water-absorbing resin

[0051] Dissolve sodium hydroxide in deionized water, slowly add acrylic acid, stir constantly to make the reaction complete, and cool the obtained neutralizing solution for later use; then dissolve chitosan in deionized water, pour it into the neutralizing solution after fully stirring, and then Add initiator potassium persulfate and cross-linking agent N,N'-methylenebisacrylamide, and stir conti...

Embodiment 3

[0055] A kind of antibacterial biodegradable water-absorbing material used for refrigerated food is obtained according to the following steps:

[0056] (1) Take raw materials by mass percentage:

[0057]

[0058] (2) Preparation of freeze-dried tea powder

[0059] Wash the fresh West Lake Longjing and dry it naturally, crush and grind the fresh tea leaves, vacuum freeze-dry the ground tea leaves at -30°C and 8Pa for 24 hours, and then crush the freeze-dried tea leaves , crushed into powder below 20 mesh for later use,

[0060] (3) Preparation of chitosan water-absorbent resin

[0061] Dissolve sodium hydroxide in deionized water, slowly add acrylic acid, stir constantly to make the reaction complete, and cool the obtained neutralizing solution for later use; then dissolve chitosan in deionized water, pour it into the neutralizing solution after fully stirring, and then Add initiator potassium persulfate and cross-linking agent N,N'-methylenebisacrylamide, and stir contin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com