3D printing wax model support material and its preparation method based on mjp technology

A technology of 3D printing and supporting materials, applied in the field of 3D printing materials, can solve the problems of scarcity of supporting materials for 3D printing wax molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

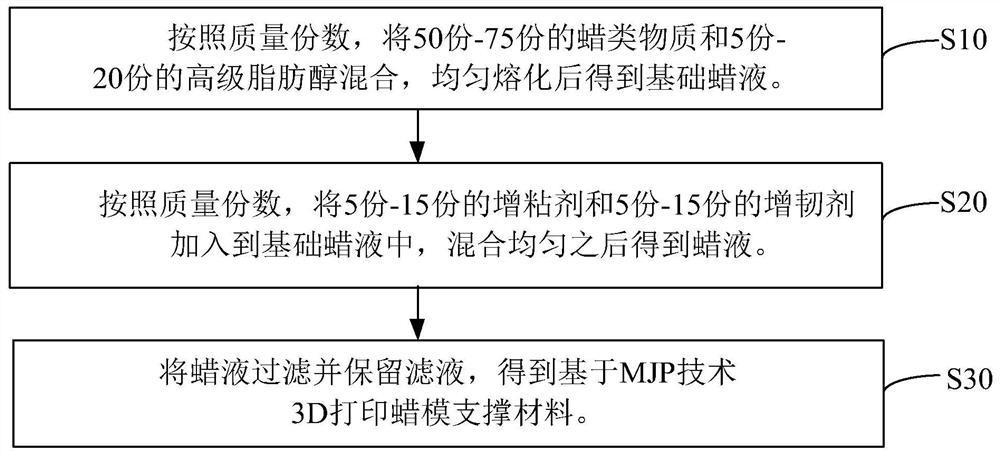

[0040] See figure 1 , a method for preparing a 3D printing wax model support material based on MJP technology according to an embodiment of the present invention, comprising the following steps:

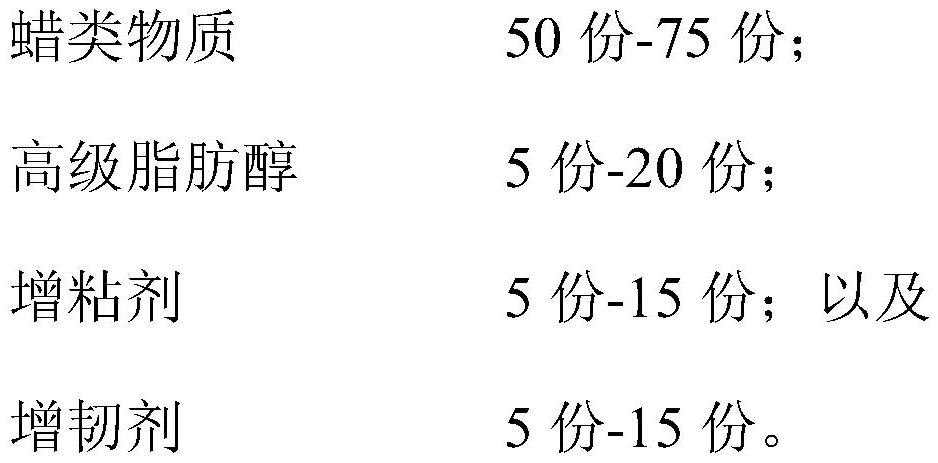

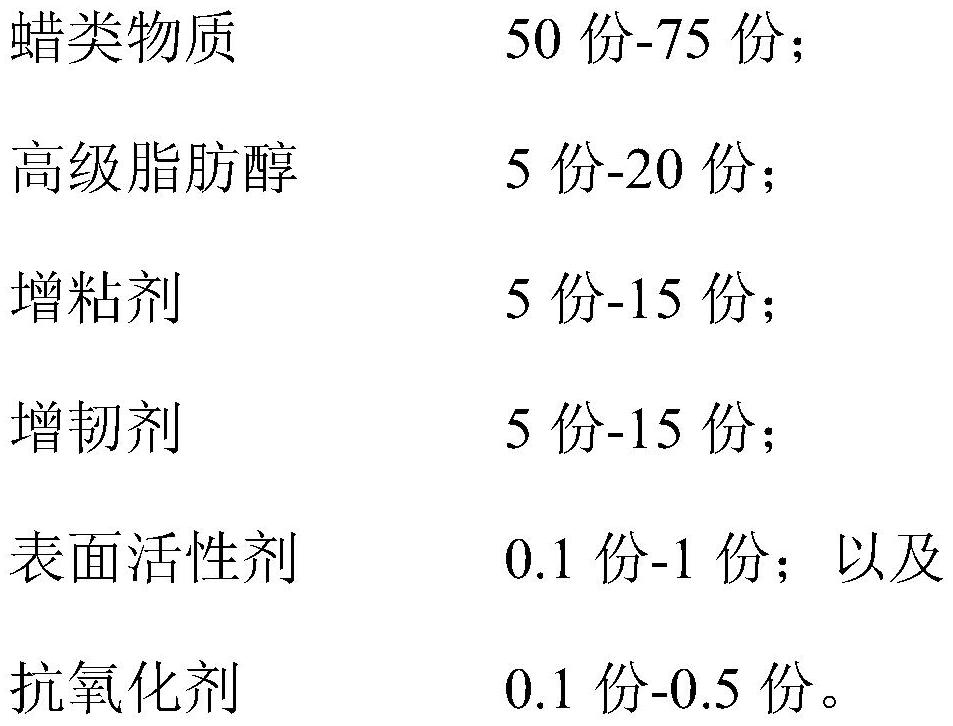

[0041] S10. Mix 50-75 parts of the wax substance and 5-20 parts of the higher fatty alcohol according to the parts by mass, and uniformly melt to obtain the base wax liquid.

[0042] Preferably, 50-75 parts of waxy substances and 5-20 parts of higher aliphatic alcohols are mixed in parts by mass, and in the operation of uniform melting: maintain the mixing temperature at 100°C-110°C. Since the above-mentioned raw materials are not solid, maintaining the mixing temperature at 100°C-110°C can make the raw materials better mixed evenly.

[0043] S20. Add 5-15 parts of tackifier and 5-15 parts of toughening agent into the basic wax liquid according to the parts by mass, and mix uniformly to obtain the wax liquid.

[0044] Preferably, the homogeneous mixing operation is: mixing by stirrin...

Embodiment 1

[0052] Add 72.4g of polyethylene glycol wax and 6.5g of cetyl alcohol into the reaction kettle, control the temperature to 100°C, and obtain the basic wax liquid after uniform melting.

[0053] Add 14.7g of water-based rosin resin, 5.3g of polyvinyl alcohol, 1g of polysorbate-80 and 0.1g of butyl hydroxyanisole into the above-mentioned basic wax liquid, control the temperature at 100°C, and stir at a stirring speed of 450r / min for 2h Afterwards a wax solution is obtained.

[0054] The above wax liquid is filtered through a suction filter bottle with a 5 μm filter element, and the filtrate is bottled to obtain a 3D printing wax model support material based on MJP technology.

Embodiment 2

[0056] Add 39.3g of polyethylene glycol wax, 9.8g of water-soluble silicone wax and 20g of behenyl alcohol into the reaction kettle according to mass percentage, adjust the temperature at 100°C, and obtain the basic wax liquid after uniform melting.

[0057] Add 10.3g rosin polyol ester resin, 4.5g alkyd resin, 9.4g polyacrylamide, 5.6g gelatin, 1g cetearyl alcohol and 0.1g 2,6-di-tert-butyl p-cresol to the above basic wax liquid In the process, the temperature was controlled at 110° C., and the wax liquid was obtained after stirring at a stirring speed of 800 r / min for 1 h.

[0058] The above wax liquid is filtered through a suction filter bottle with a 5 μm filter element, and the filtrate is bottled to obtain a 3D printing wax model support material based on MJP technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com