A method of extracting aluminum oxide from fly ash

A fly ash and alumina technology, applied in chemical instruments and methods, alumina/aluminum hydroxide, inorganic chemistry, etc., can solve the problems of waste of fly ash resources, large amount of tailings, secondary pollution, etc. Achieve the effect of solving high cost, reducing production cost and increasing safe supply

Inactive Publication Date: 2016-02-10

常州深海环保科技有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the sintering method needs to add a large amount of lime to react at high temperature (>1150°C), the energy consumption is high, and the tailings are produced in a huge amount, causing serious secondary pollution problems

[0006] At present, the main purpose is to extract alumina from fly ash. The production process not only consumes a lot of energy, but also causes waste of resources of valuable elements in fly ash, causing secondary pollution problems.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0131] The present application is explained by the following examples, but those skilled in the art should understand that the present application is not limited to the specific examples. In this example, the analysis of the chemical composition was determined by the national standard GB / T1574-1995 method.

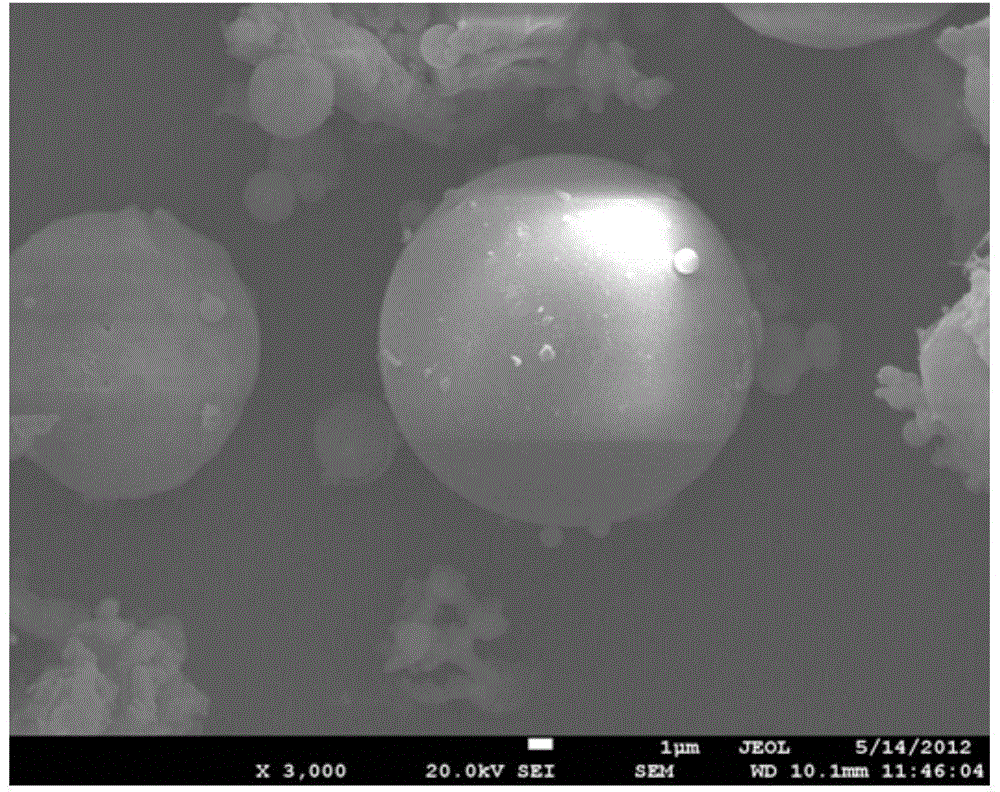

[0132] Activation of fly ash to produce activated fly ash

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

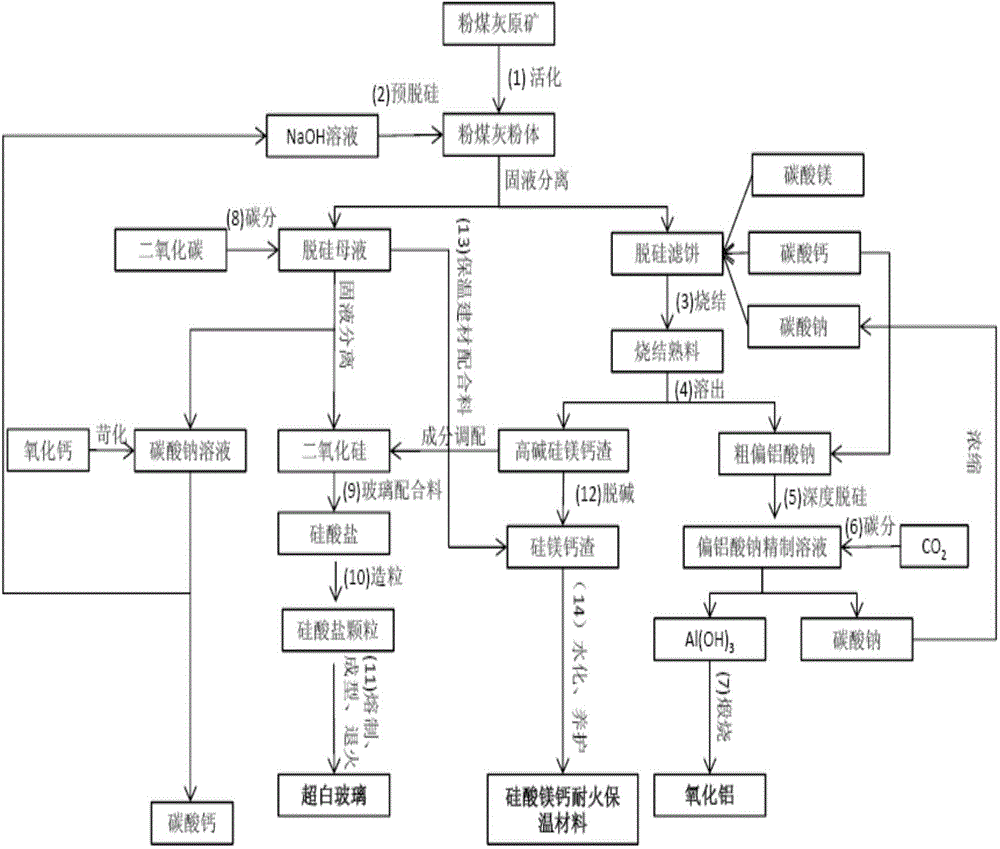

The invention relates to a method of extracting aluminum oxide from coal ash and particularly relates to an integrated method for extracting aluminum oxide from a large quantity of coal ash discharged by an industrial solid waste coal-fired power plant and co-producing ultra clear glass and a calcium magnesium silicate material serving as a fireproof insulating material. The successfully developed method can thoroughly solve the problem that an ash storage field of the power plant occupies a large area and coal ash causes pollution, so that the comprehensive utilization ratio of coal ash is improved. The problem of resource shortage of bauxite is solved, so that safe supply of aluminum sources is effectively increased. The method solves the problems that extraction of aluminum from coal ash is high in cost, single type of product is generated, and secondary pollution is caused. The method solves the problem of rare raw materials for ultra clear glass production, so that the production cost of the ultra clear glass is greatly lowered.

Description

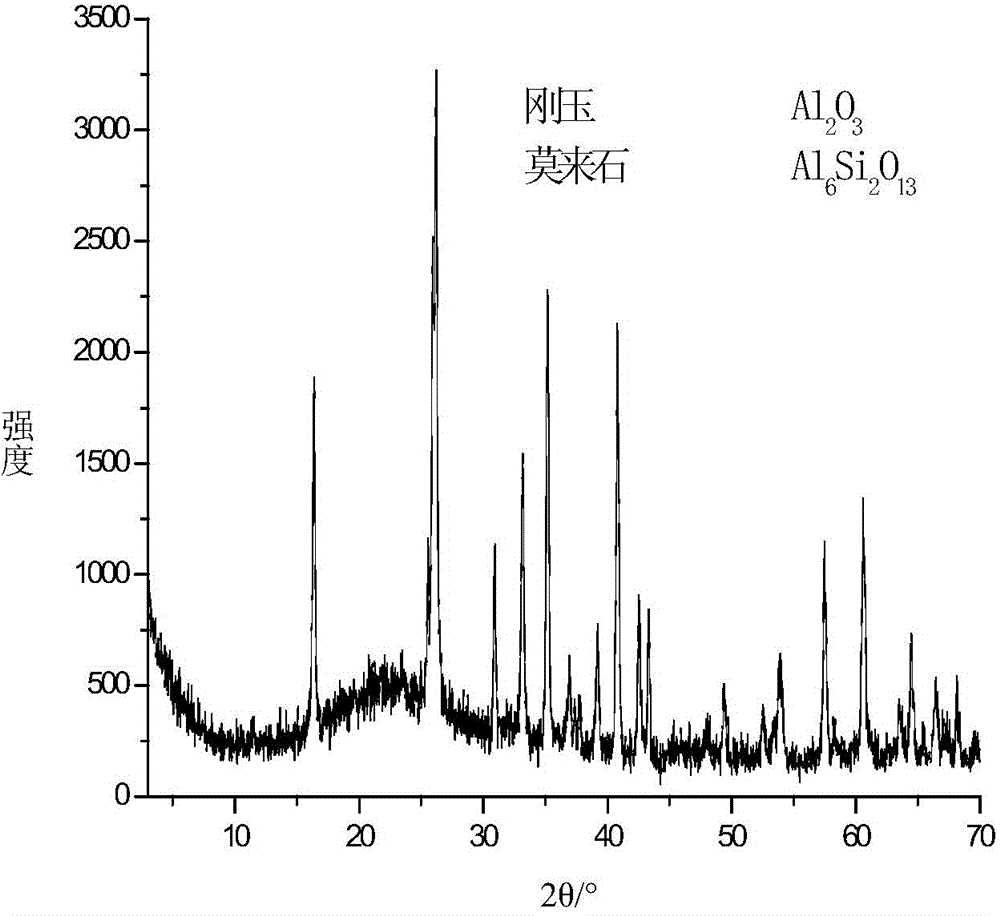

technical field [0001] This application relates to a method of extracting alumina from fly ash. In particular, it relates to an integrated method for extracting alumina from fly ash discharged from bulk industrial solid waste coal-fired power plants, and co-producing ultra-clear glass and magnesium-calcium silicate materials as refractory and thermal insulation materials. Background technique [0002] In China, fly ash is mainly high-aluminum fly ash, which is the main solid waste discharged from coal-fired power plants. The main oxide composition of fly ash is: SiO 2 、Al 2 o 3 , FeO, Fe 2 o 3 , CaO, TiO 2 etc., and associated impurity elements such as vanadium, lead, gallium, germanium, etc. Among them, more than 90% of the aluminum exists in the mullite-corundum crystal phase in the form of alumina and aluminosilicate, and the silicon oxide content is about 40%. [0003] At present, the methods for extracting alumina from fly ash mainly include acid and alkali proc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01F7/02C01F7/44C03C3/087C04B7/24

CPCY02P40/10Y02P40/18

Inventor 孙琦王宝冬马铜锁

Owner 常州深海环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com