Method of producing high color value red yeast rice from mixed raw materials

A technology of mixing raw materials and high color value, which is applied in the field of red yeast rice fermentation, can solve the problems of increasing processing cost and use cost, and unsatisfactory color value, and achieve the effects of increasing color value, reducing viscosity, and increasing dissolved oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

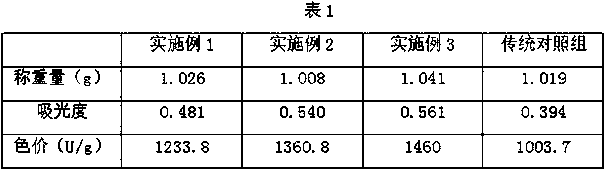

Examples

Embodiment 1

[0024] (1) Separation and purification of Monascus, cultured on a slant for 6 days at a temperature of 32°C;

[0025] (2) After the slant culture is completed, transfer to the liquid culture medium for liquid culture, the culture time is 1d, and the culture temperature is 33°C;

[0026] (3) After liquid culture, get the inoculum, spread the inoculum with a mass fraction of 10%, transfer it to 200ml liquid medium, and cultivate for 1d; get the diffusion culture, then transfer the diffusion culture to In 2L liquid medium, culture time is 1d to obtain the final inoculum;

[0027] (4) Separate the final inoculum into tanks and carry out culture in a liquid fermenter for 2 days to obtain a bacterium culture medium;

[0028] The liquid medium components used in steps (2), (3) and (4) in this example include 17 parts by mass of rice flour, 13 parts of soybean flour, 12 parts of potato flour, 8 parts of glucose, and 2 parts of yeast extract -Parts and NaNO 3 0.7 parts.

[0029] (...

Embodiment 2

[0031] (1) Separation and purification of Monascus, cultured on a slant for 8 days at a temperature of 34°C;

[0032] (2) After the slant culture is completed, transfer to the liquid medium for liquid culture, the culture time is 2 days, and the culture temperature is 35°C;

[0033] (3) After liquid culture, get the inoculum, spread the inoculum with a mass fraction of 10%, transfer it to 200ml liquid medium, and cultivate for 2 days; get the diffusion culture, then transfer the diffusion culture to In 2L liquid medium, the culture time is 2 days to obtain the final inoculum;

[0034] (4), the final inoculum was divided into tanks, and cultured in a liquid fermenter for 4 days to obtain a bacterium culture medium;

[0035] The liquid medium components used in steps (2), (3) and (4) in this example include 21 parts by mass of rice flour, 16 parts of soybean flour, 13 parts of potato flour, 10 parts of glucose, and 3 parts of yeast extract Parts and NaNO 3 1 serving.

[003...

Embodiment 3

[0038] (1) Separation and purification of Monascus, cultured on a slant for 9 days at a temperature of 36°C;

[0039] (2) After the slant culture is completed, transfer to the liquid medium for liquid culture, the culture time is 3 days, and the culture temperature is 37°C;

[0040] (3) After liquid culture, get the inoculum, spread the inoculum with a mass fraction of 10%, transfer it to 200ml liquid medium, and cultivate for 3 days; get the diffusion culture, then transfer the diffusion culture to In 2L liquid medium, the culture time is 3 days to obtain the final inoculum;

[0041] (4) Divide the final inoculum into tanks and carry out culture in a liquid fermenter for 5 days to obtain a bacterium culture medium;

[0042] The liquid medium components used in steps (2), (3) and (4) in this example include 25 parts by mass of rice flour, 18 parts of soybean flour, 15 parts of potato flour, 12 parts of glucose, and 4 parts of yeast extract Parts and NaNO 3 1.3 servings.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com