Preparation method of aqueous aluminium ion battery cathode, and aqueous aluminium ion battery

A technology of aluminum ion battery and negative electrode, which is applied in the direction of electrode manufacturing, battery electrode, electrode collector coating, etc., to achieve the effects of stable structure, avoiding low cycle stability and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Embodiments of the present invention provide a method for preparing a negative electrode of an aqueous aluminum ion battery, which includes:

[0024] Na 2 V 6 o 16 ·3H 2 O the negative electrode material is mixed with a conductive agent and a binder according to a preset ratio to obtain a mixture;

[0025] Add deionized water to the mixture and stir to form a homogeneous slurry;

[0026] The slurry is coated on the current collector and dry roll die cut.

[0027] Further, in a preferred embodiment of the present invention, Na 2 V 6 o 16 ·3H 2 O The negative electrode material is mixed with the conductive agent and the binder according to a preset ratio of 8:1:1. Of course, in other embodiments of the present invention, the amount of negative electrode material, conductive agent and binder can also be selected according to requirements, which are not limited in this embodiment of the present invention.

[0028] Further, in a preferred embodiment of the present ...

Embodiment 1

[0045] This embodiment provides a method for preparing a negative electrode of an aqueous aluminum ion battery, which includes:

[0046]S1: At room temperature, 0.546gV 2 o 5 and 0.142gNa 2 SO 4 Dissolve in 30ml of distilled water and stir for 1 hour to obtain a mixed solution;

[0047] S2: The mixed solution was transferred to a 50ml Teflon-lined stainless steel autoclave, and hydrothermally reacted at 180°C for 24h, and then cooled to room temperature to obtain the first product;

[0048] S3: alternately washing the red-brown product three times with distilled water and absolute ethanol for the first product and centrifuging to obtain the washed second product;

[0049] S4: the washed second product is placed in a vacuum oven at 60°C for 12 hours to obtain Na 2 V 6 o 16 ·3H 2 O anode material;

[0050] S5: Prepared Na 2 V 6 o 16 ·3H 2 O negative electrode material is mixed with conductive agent, binding agent according to mass ratio 8:1:1 to obtain mixture;

[...

experiment example 1

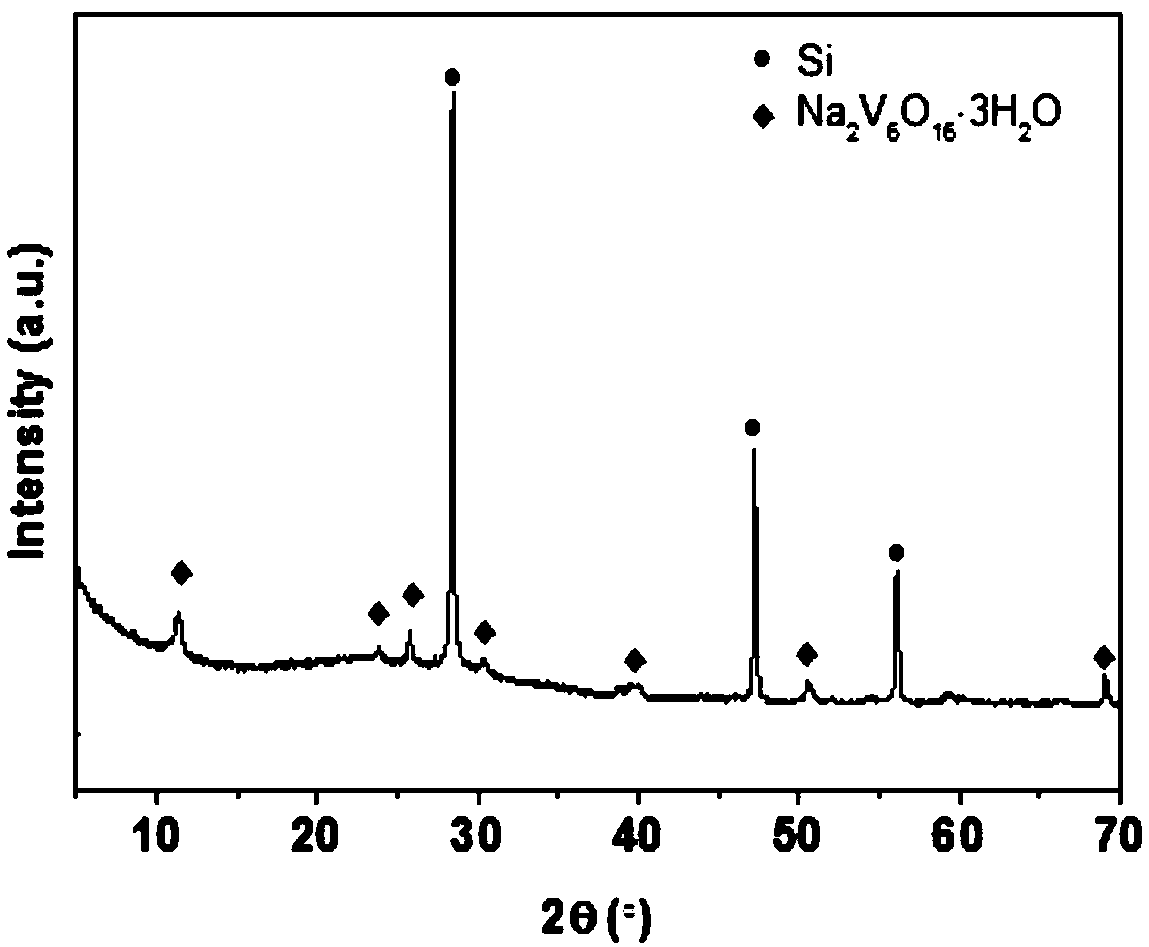

[0054] The XRD spectrum of the negative electrode material that embodiment 1 prepares is as figure 1 As shown, with silver-silver chloride as the reference electrode, graphite rod electrode For the counter electrode, the electrolyte is 1mol L -1 Al(NO 3 ) 3 aqueous solution, and the electrochemical performance test of the prepared negative electrode was carried out.

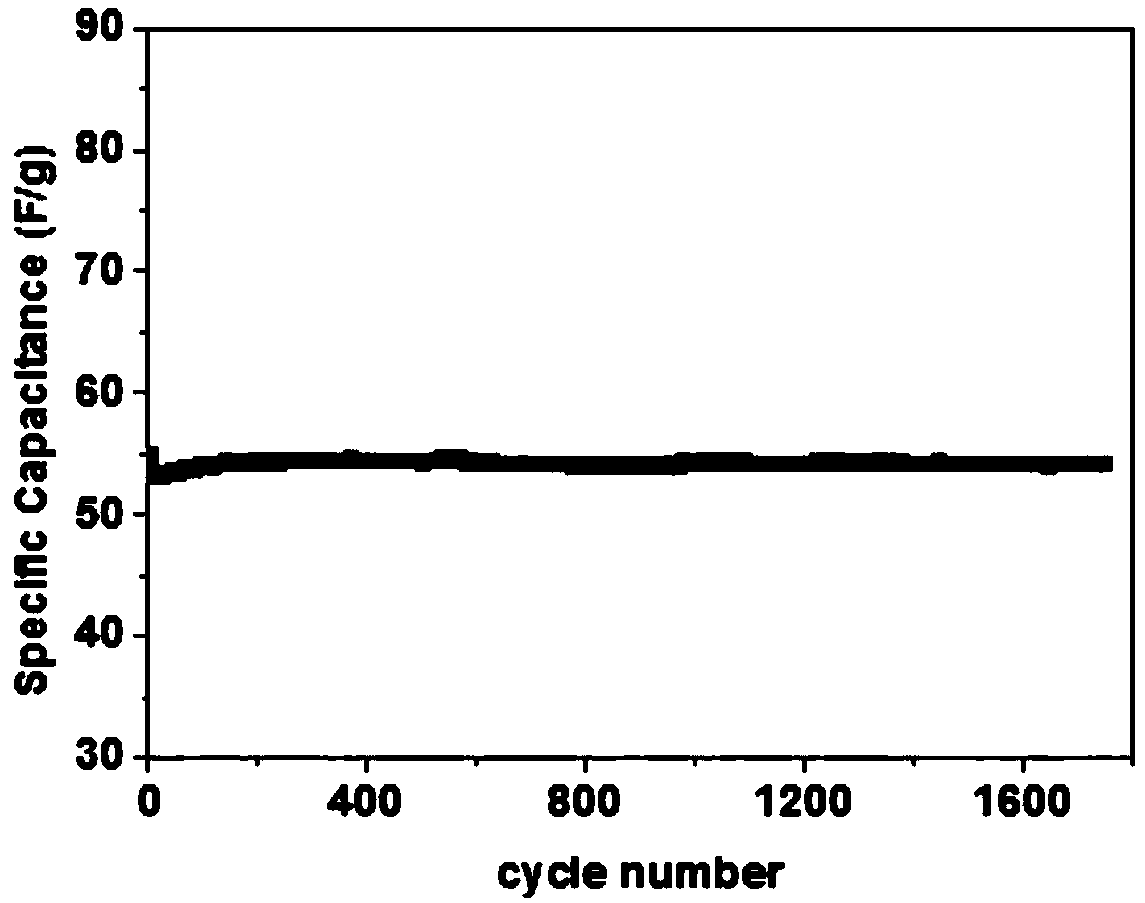

[0055] Such as figure 2 As shown, Na 2 V 6 o 16 ·3H 2 The first discharge specific capacity of O is 54.8F / g. After 100 cycles, the specific capacity remains basically unchanged. After 1700 cycles, the discharge specific capacity is 54.1F / g, the capacity retention rate is 98.7%, and the cycle stability is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com