Preparation method of electrocatalyst for oxygen evolution reaction

A technology of electrocatalyst and oxygen evolution reaction, which is applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the problems of poor electrical conductivity, limited Pt reserves, high catalyst cost, etc., and achieve low cost, simple preparation process, and improved catalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

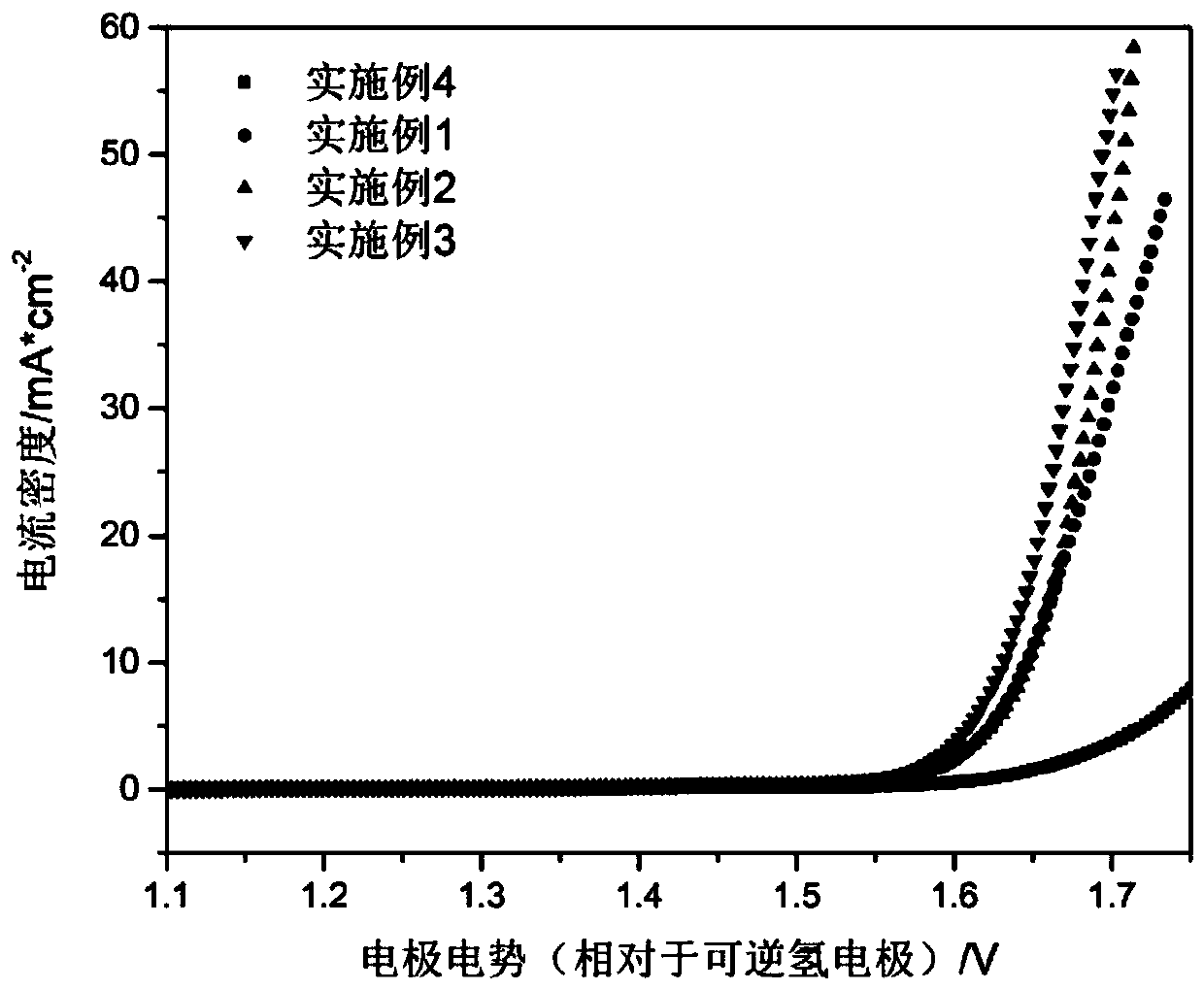

Embodiment 1

[0024] 1) Ventilate and dry 200g of goat blood purchased on the market at 90°C for 6 hours, grind and pulverize it for 10 minutes, weigh 1.011g of the powder and put it in a porcelain boat;

[0025] 2) Place the porcelain boat in a tube furnace, fill it with nitrogen atmosphere, set the heating rate at 5°C / min, and keep it at the target temperature of 600°C for 2 hours to obtain the precursor;

[0026] 3) Take 29ml of deionized water, weigh 0.144g of cobalt acetate tetrahydrate and put it in. The precursor in step 2) is ground and put in together. After mixing, ultrasonically oscillate for 20 minutes, magnetically stir for 20 minutes, and then ultrasonically oscillate for 20 minutes ;

[0027] 4) Transfer the mixed solution in step 3) to a hydrothermal kettle, add 1ml of ammonia water, keep the hydrothermal kettle at 150°C for 2 hours, take it out, wash it with deionized water after cooling, and ventilate and dry at 60°C for 24 hours , to obtain the finished electrocatalyst Y...

Embodiment 2

[0030] 1) 230g of goat blood purchased in the market was ventilated and dried at 80°C for 5 hours, ground and pulverized for 15 minutes, and 1.004g of the powder was weighed and placed in a porcelain boat;

[0031] 2) Place the porcelain boat in a tube furnace, fill it with nitrogen atmosphere, set the heating rate at 6°C / min, and keep it at the target temperature of 650°C for 2.5h to obtain the precursor;

[0032] 3) Take 28ml of deionized water, weigh 0.299g of cobalt acetate tetrahydrate and put it in. The precursor in step 2) is ground and put in together. After mixing, ultrasonically oscillate for 25 minutes, magnetically stir for 25 minutes, and then ultrasonically oscillate for 20 minutes ;

[0033] 4) Transfer the mixture in step 3) to a hydrothermal kettle, add 2ml of ammonia water, keep the hydrothermal kettle at 160°C for 2.5h, take it out, wash it with deionized water after cooling, and place it at 65°C to ventilate and dry After 24 hours, the finished electrocata...

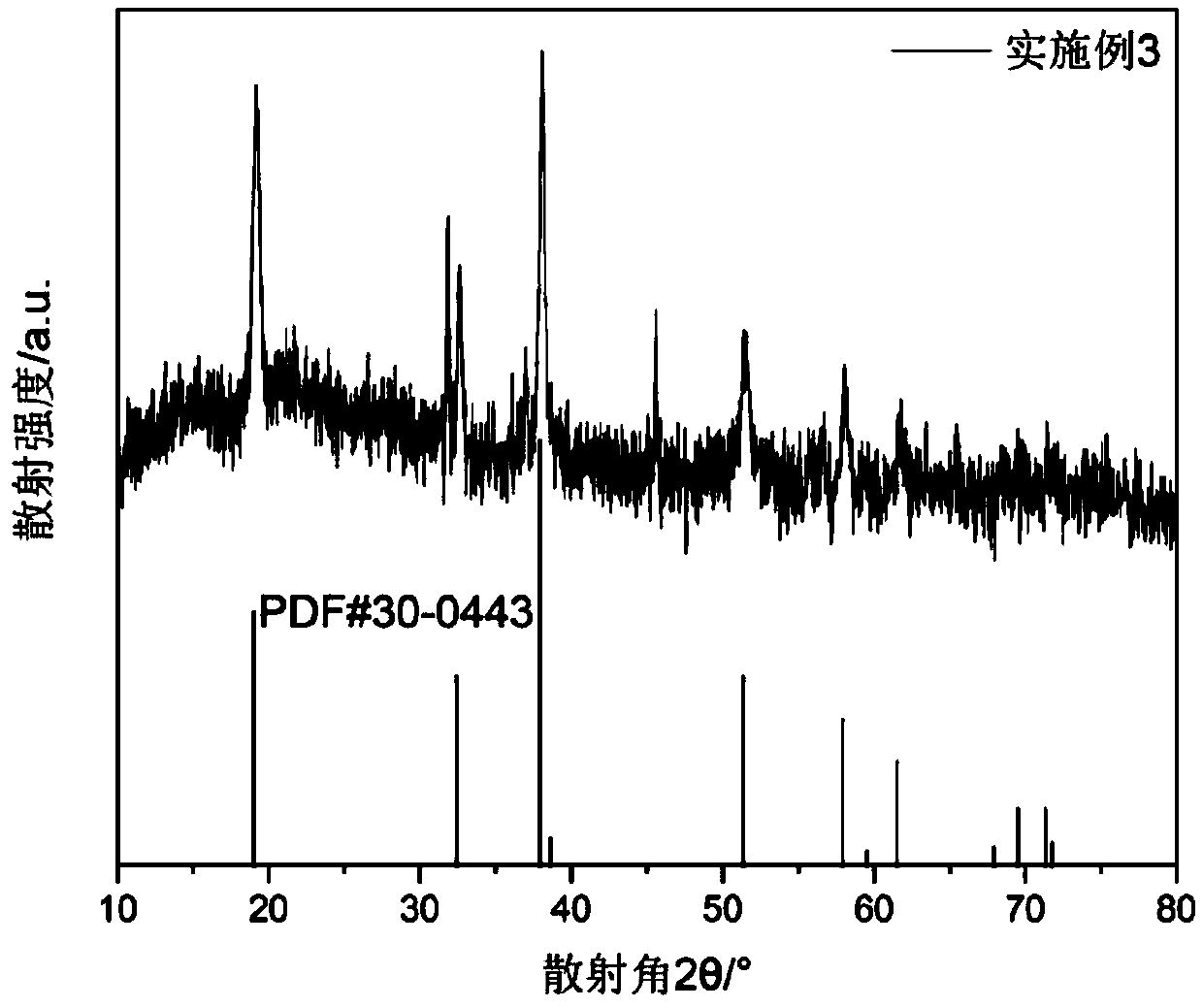

Embodiment 3

[0036] 1) Ventilate and dry 250g of goat blood purchased on the market at 95°C for 7 hours, grind and pulverize it for 20 minutes, weigh 1.000g of the powder and put it in a porcelain boat;

[0037] 2) Place the porcelain boat in a tube furnace, fill it with nitrogen atmosphere, set the heating rate at 8°C / min, and keep it at the target temperature of 700°C for 3 hours to obtain the precursor;

[0038] 3) Take 27ml of deionized water, weigh 0.434g of cobalt acetate tetrahydrate and put it in. The precursor in step 2) is ground and put in together. After mixing, ultrasonically oscillate for 15 minutes, magnetically stir for 15 minutes, and then ultrasonically oscillate for 25 minutes ;

[0039] 4) Transfer the mixed solution in step 3) to a hydrothermal kettle, add 3ml of ammonia water, keep the hydrothermal kettle at 170°C for 2 hours, take it out, wash it with deionized water after cooling, and place it at 55°C to ventilate and dry for 24 hours , to obtain the finished elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com